OPERATION

OPERATION

3-66

OPERATION

3

CHECK BEFORE STARTING ENGINE, ADJUST

3

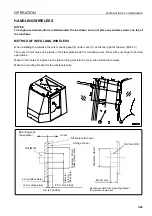

WALK-AROUND CHECK

3

Before starting the engine, walk around the machine and look at the underside of chassis for anything unusual like

loose bolts and nuts, leakage of fuel, oil and coolant. Also check the condition of the work equipment and the

hydraulic system.

Also check for loose wiring, play, and collection of dust at places that reach high temperature.

WARNING

q

Always hang a warning sign on the work equipment control levers.

q

Spilled fuel or oil or accumulation of flammable materials around the battery or other high-temperature

parts of the engine, such as the engine muffler or turbocharger will cause fire on the machine. Always

check thoroughly and repair any problems or contact your Komatsu distributor.

q

Always repair any damage to the handrails and steps, and tighten any loose bolts. Failure to do this

may cause workers to fall and suffer serious personal injury.

If the machine is at an angle, reposition it level before checking.

Always carry out the items in this section before starting the engine each day.

1.

Check for damage, wear, play in work equipment, cylinders, linkage and hoses.

Check that there are no cracks, excessive wear, or play in the work equipment, cylinders, linkage, or hoses. If

any abnormality is found, repair it.

2.

Remove dirt and dust from around engine, battery and radiator.

Check that there is no dirt accumulated in the radiator or around the engine. Check also that there are no flam-

mable materials (dry leaves, twigs, etc) accumulated around the battery or other high-temperature parts of the

engine, such as the engine muffler or turbocharger. If any dirt or flammable materials are found, remove them

immediately.

3.

Check for coolant or oil leakage around the engine.

Check that there is no oil leakage from the engine or coolant leakage from the cooling system. If any problem

is found, repair it.

4.

Check for leakage of oil from transmission case, axle, hydraulic tank, hoses, joints.

Check that there is no oil leakage. If any abnormality is found, repair the leakage.

5.

Check for oil leakage from the brake line.

Check that there is no oil leakage. If any abnormality is found, repair the leakage.

6.

Check for damage or wear to tires and loose mounting bolts.

Check for cracks or peeling of the tires and for cracks or wear to the wheels (side rim, rim base, lock ring).

Tighten any loose wheel bolts. If any abnormality is found, repair or replace the part.

If any valve caps are missing, install new caps.

7.

Check for damage and loose bolts on the handrail and steps.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

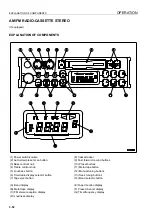

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...