OPERATION

OPERATION

3-77

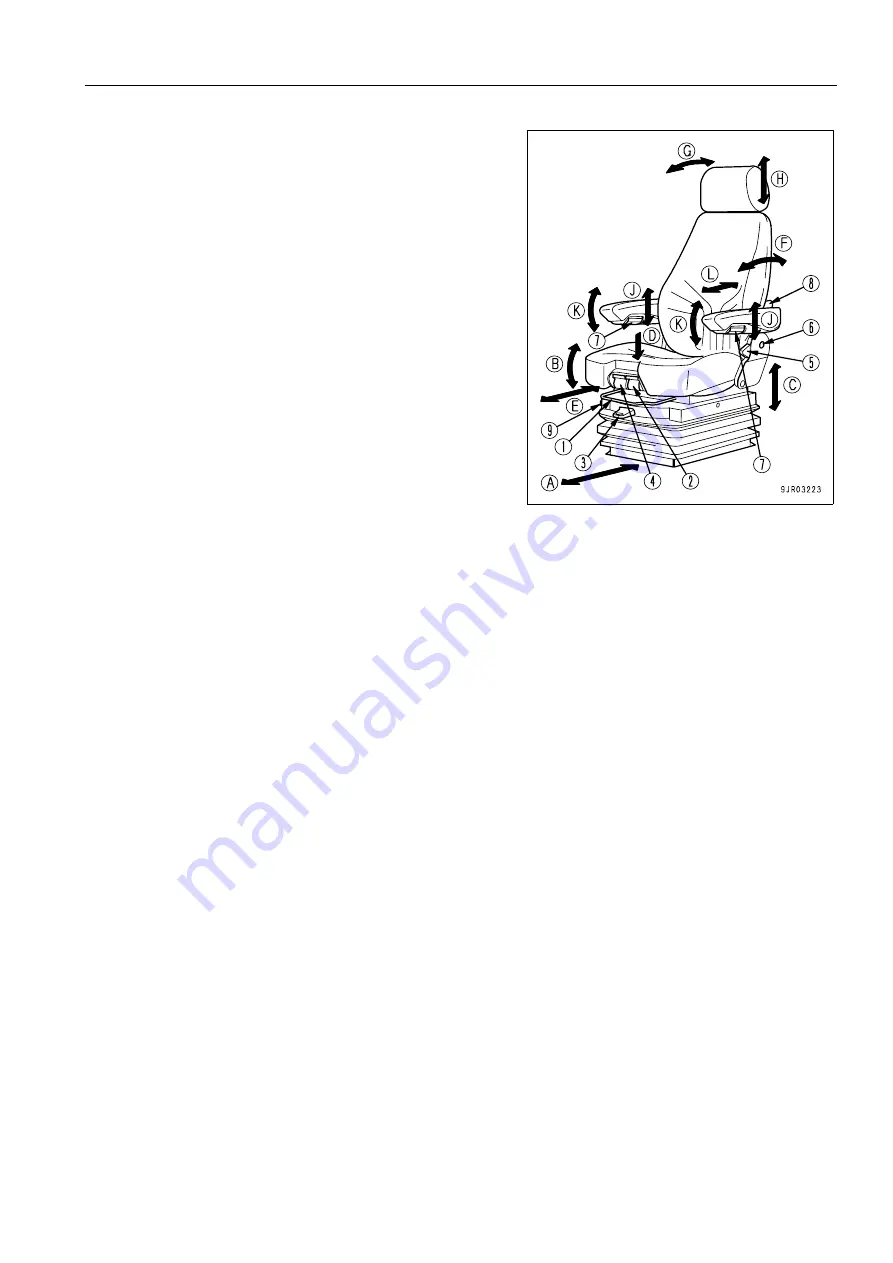

(A) Fore-and-aft adjustment

Move lever (1) up and move the seat to the desired position

and release the lever.

Fore-and-aft adjustment: 210 mm (10 mm x 21 stages)

(B) Adjusting seat angle

Move lever (2) up, move the seat cushion at the front up or

down to set to the desired position, then release the lever.

Amount of adjustment

Forward tilt: 3 degrees

Rear tilt: 11 degrees

(C) Adjusting seat height

The seat height adjustment uses an air system, and it can be

adjusted steplessly.

When adjusting the height, pull lever (3) up fully or push it down fully (when pulling it up, pull it until a click is felt).

When the seat is set at the desired height, release the lever. If the lever is kept pulled up, the position where the

seat does not rise any further is the maximum height. When the seat reaches the maximum height, the suspen-

sion automatically goes down slightly to secure the amount of movement of the lever.

If the operator raises his body from the seat or changes the amount of weight applied to the seat during adjust-

ment, the air in the suspension may be discharged.

Amount of adjustment: 80 mm

REMARK

If lever (3) is pulled up further from the maximum height, the air compressor may make a sound of actuation but

the seat may not rise. This does not indicate any abnormality.

If this happens, the air compressor will stop automatically after approx. 8 seconds. It will also stop if lever (3) is

pushed down.

(D) Setting seat for weight

To protect the operator, it is necessary to adjust the suspension to match the operator's weight. When carrying out

this adjustment, stop the machine, set the seat to the correct posture, then operate the lever.

Pull up lever (3) lightly a short distance. The weight setting is adjusted automatically. (The air pressure inside the

suspension is increased or decreased to match the operator's weight.)

REMARK

When making initial adjustment or when adjusting the weight settings when operators change shifts, set the damp-

ing force of the suspension damper to the soft setting (for details, see “Adjusting hardness of suspension

damper“), then adjust it to match the operator's weight. If the damping force of the suspension damper is left set to

the hard setting and the height of the seat is adjusted, even if the height is raised, the seat may go down. If the

seat goes down, set the damping force of the suspension damper to the soft setting, lower the seat, then adjust the

weight again. After completing adjustment of the weight and height, set the damping force of the suspension

damper to the desired strength.

To protect the operator, the suspension must be adjusted to match the operator's weight. Adjust the weight before

starting operations.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...