SERVICE PROCEDURE

MAINTENANCE

4-24

CLEAN INSIDE OF COOLING SYSTEM

4

WARNING

q

Immediately after the engine is stopped, the coolant is at high temperature and the radiator is under

high internal pressure. If the cap is removed in this condition and the water is drained, it will cause

burns. Wait for the temperature to go down, then turn the cap slowly to release the pressure.

q

The engine is run during the flushing operation. Before standing up from or leaving the operator's

seat, always set the lock lever (work equipment, steering) to the LOCK position.

q

For details of the procedure when starting the engine, see “CHECK BEFORE STARTING ENGINE,

ADJUST (3-66)“ and “STARTING ENGINE (3-83)“.

q

When the engine is running, never go inside the rear of the machine.

Clean the inside of the cooling system, change the coolant and replace the corrosion resistor according to the

table below.

*: Permanent type antifreeze shall meet the requirements of ASTM D3306-03.

Stop the machine on level ground when cleaning or changing the coolant.

The coolant has the important function of preventing corrosion as well as preventing freezing.

Even in the areas where freezing is not an issue, the use of antifreeze coolant is essential.

Komatsu machines are supplied with Komatsu Supercoolant (AF-NAC). Komatsu Supercoolant (AF-NAC) has

excellent anticorrosion, antifreeze and cooling properties and can be used continuously for 2 years or 4000 hours.

Komatsu Supercoolant (AF-NAC) is strongly recommended wherever available.

To maintain the anticorrosion properties of Supercoolant (AF-NAC), always keep the density of Supercoolant

between 30% and 68%.

When deciding the ratio of antifreeze to water, check the lowest temperature in the past, and decide from the mix-

ing table given below.

It is actually better to estimate and temperature about 10°C lower when deciding the mixing ratio.

The mixing ratio depends on the ambient temperature, but it should always be a minimum of 30% by volume (anti-

freeze/total amount of coolant x 100).

The freezing temperature of undiluted antifreeze is -15°C. Do not store undiluted antifreeze at a temperature of

below -15°C.

Antifreeze coolant

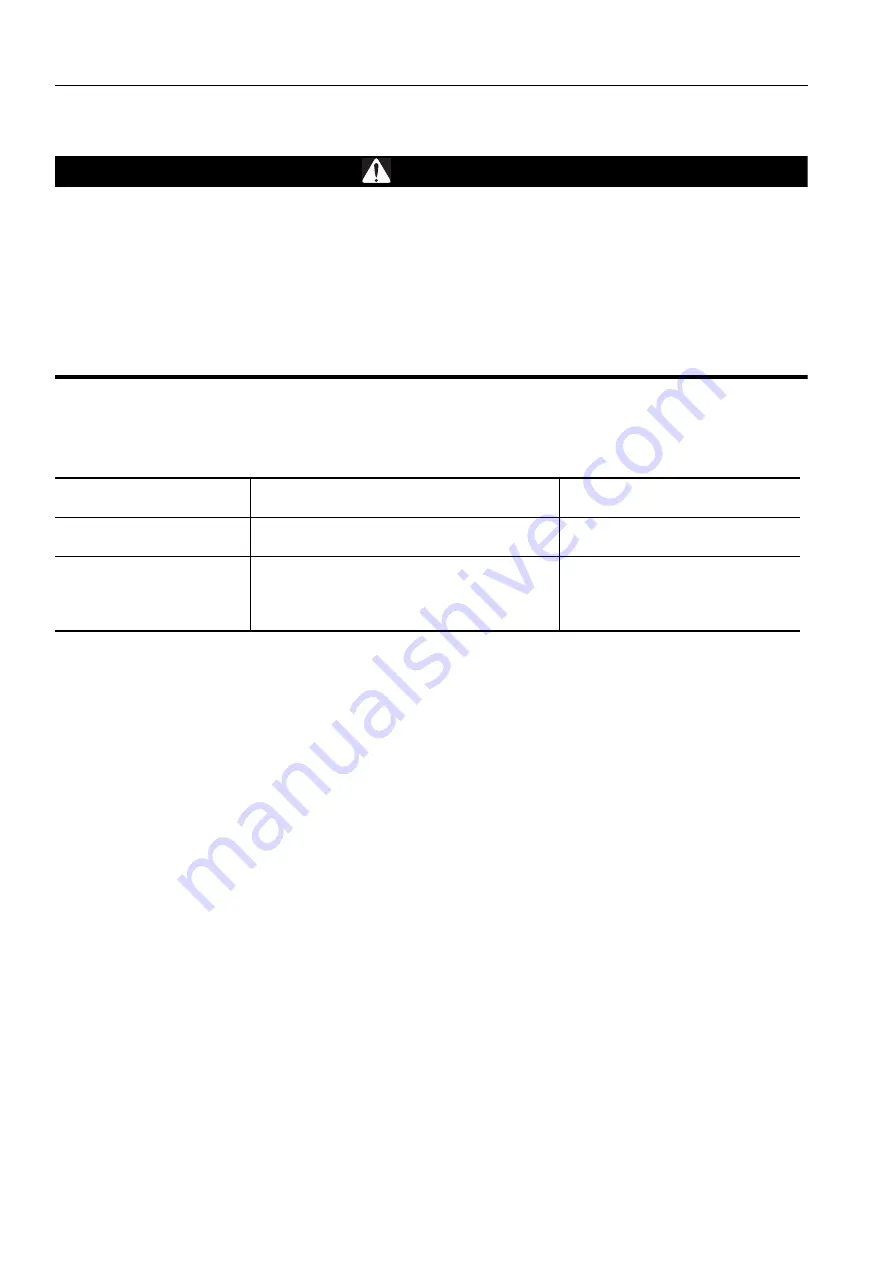

Interval of cleaning inside of cooling system

and changeing antifreeze coolant

Replacing corrosion resistor

Komatsu supercoolant

(AF-NAC)

Every two years or every 4000 hours which-

ever comes first

unnecessary

Permanent type antifreeze

(All-season type, *)

Every year (autumn) or every 2000 hours

whichever comes first

Every 1000 hours

and when cleaning the inside

of the cooling system

and when changing coolant

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...