MAINTENANCE

SERVICE PROCEDURE

4-49

EVERY 250 HOURS SERVICE

4

Maintenance for every 50 and 100 hours service should be carried out at the same time.

CHECK BATTERY ELECTROLYTE LEVEL

4

Carry out this procedure before operating the machine.

WARNING

q

Do not use the battery if the battery electrolyte level is below the LOWER LEVEL line. This will acceler-

ate deterioration of the inside of the battery and reduce the service life of the battery. In addition, it

may cause an explosion.

q

The battery generates flammable gas and there is danger of explosion, do not bring fire or sparks near

the battery.

q

Battery electrolyte is dangerous. If it gets in your eyes or on your skin, wash it off with a large amount

of water and consult a doctor.

q

When adding distilled water to the battery, do not allow the battery electrolyte to go above the UPPER

LEVEL line. If the electrolyte level is too high, it may leak and cause damage to the paint surface or

corrode other parts.

NOTICE

If there is danger of the electrolyte freezing if distilled water is added, add the distilled water before start-

ing operations on the next day.

Inspect the battery electrolyte level at least once a month and follow the basic safety procedures given below.

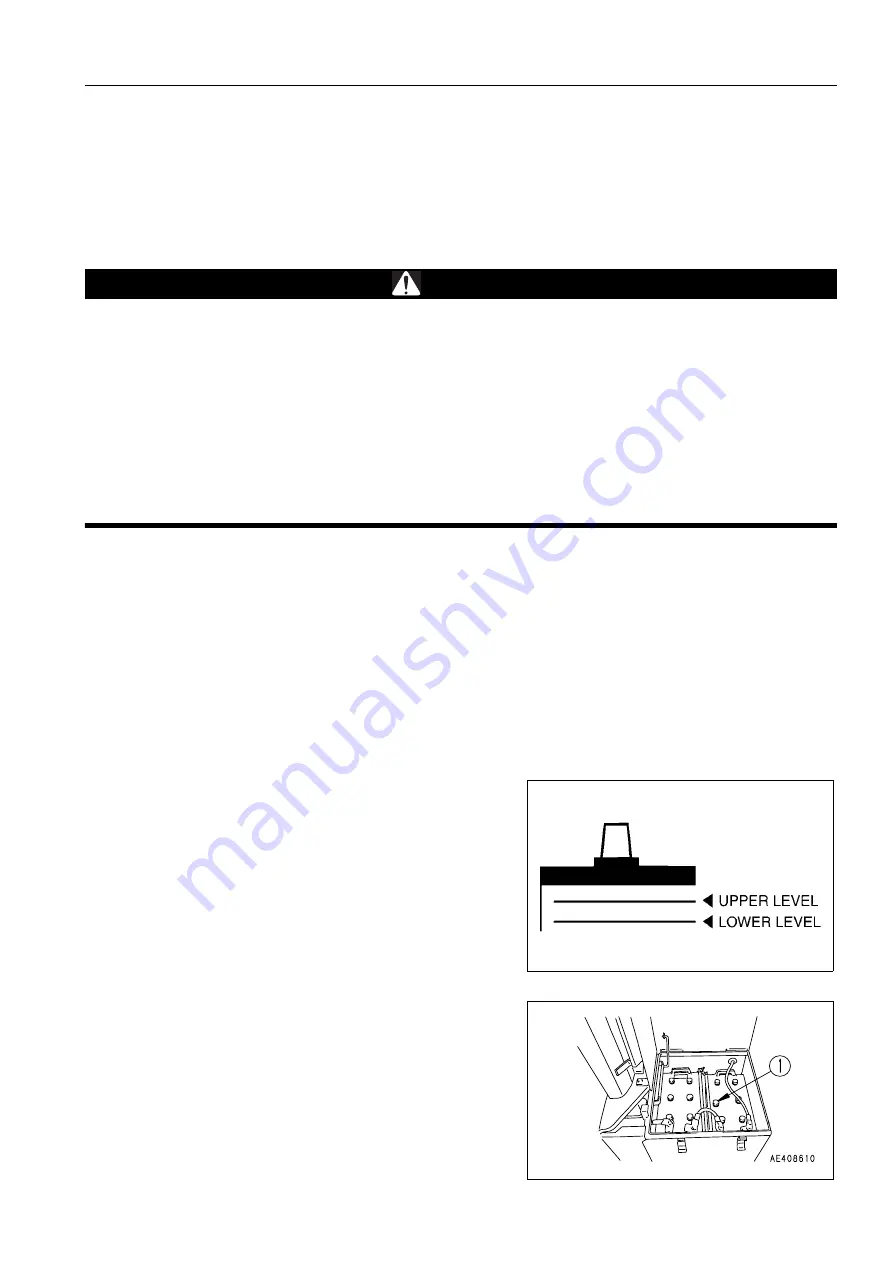

WHEN CHECKING ELECTROLYTE LEVEL FROM SIDE OF BATTERY

If it is possible to check the electrolyte level from the side of the battery, check as follows.

1.

Use a wet cloth to clean the area around the electrolyte

level lines and check that the electrolyte level is between

the UPPER LEVEL (U.L.) and LOWER LEVEL (L.L.) lines.

If the battery is wiped with a dry cloth, static electricity may

cause a fire or explosion.

2.

If the electrolyte level is below the mid point of U.L and L.L

marks, remove the cap (1) immediately and add the dis-

tilled water.

3.

After adding distilled water, tighten cap (1) securely.

REMARK

If distilled water is added to above the U.L. line, use a syringe

to lower the level to the U.L. line. Neutralize the removed fluid

with baking soda (sodium bicarbonate), then flush it away with

a large amount of water or consult your Komatsu distributor or

battery maker.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...