MAINTENANCE

SERVICE PROCEDURE

4-53

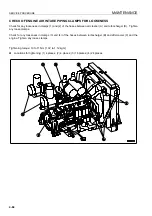

CHECK FOR LOOSE WHEEL HUB NUTS, TIGHTEN

4

If wheel hub nuts (1) are loose, tire wear will be increased and accidents may be caused.

1.

Check for loose nuts, and tighten if necessary.

When checking for loose nuts, always turn the nuts in the

direction of tightening to check.

Tightening torque: 735.7 to 912.3 Nm (75 to 93 kgm)

2.

If any stud bolt is broken, replace all the stud bolts for that

wheel.

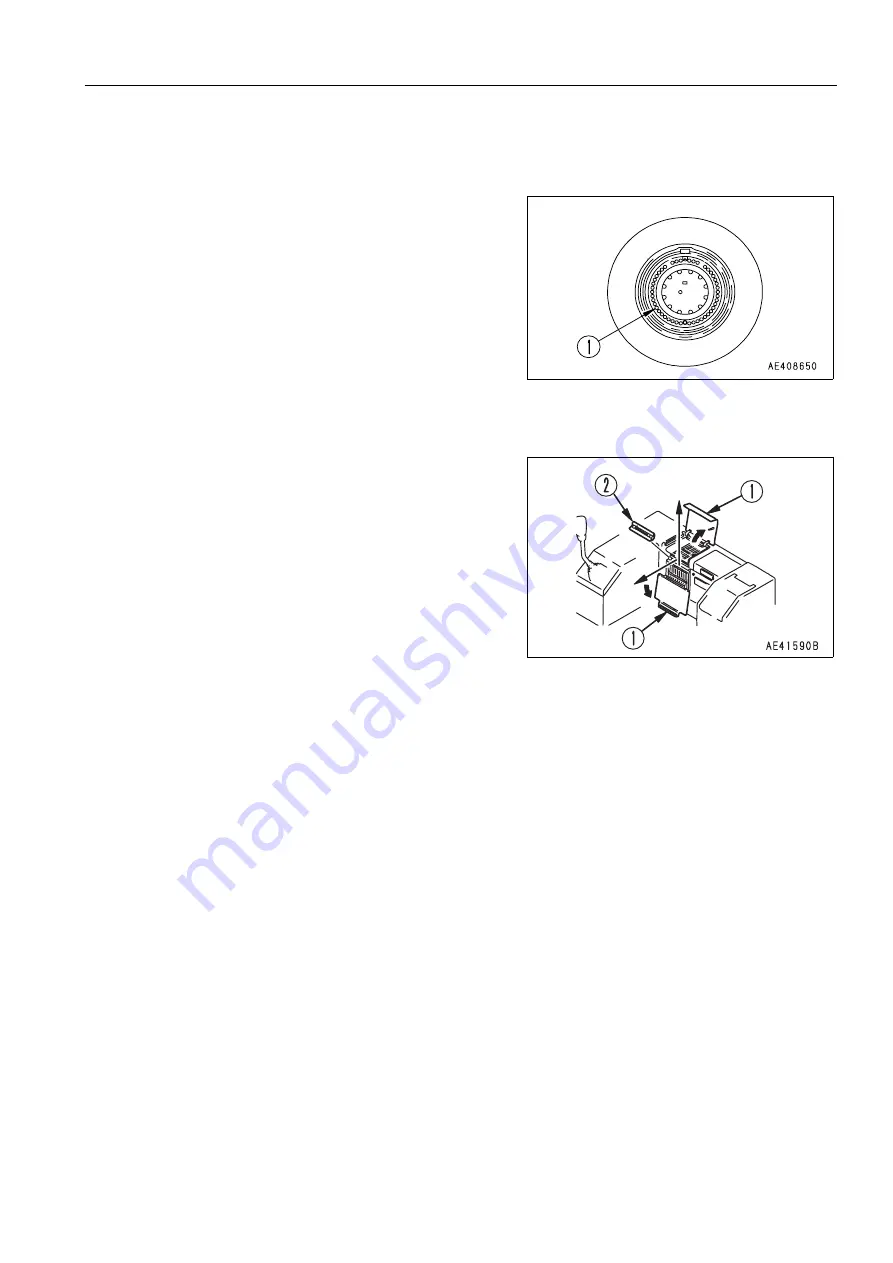

CLEAN ELEMENT IN AIR CONDITIONER RECIRCULATION FILTER

4

1.

Open the filter inspection covers (1), remove the filter cover

(2), then pull out the filter in the direction of the arrow.

Note: when removing the filter facing to the side, push the

seat down fully first.

2.

Clean with compressed air in the same way as for the fresh

air filter.

If the filter is extremely dirty, rinse it in water.

After rinsing the filter, dry it completely before installing it

again.

CHECKING FUNCTION OF ACCUMULATOR

4

For details of handling the accumulator, see Section “ACCUMULATOR (2-36)“.

BRAKE ACCUMULATOR

If the engine stops when the machine is traveling, the oil pressure in the accumulator can be used to apply the

brake as an emergency measure.

1.

Stop the machine on level ground and lower the work equipment completely to the ground.

2.

Apply the parking brake.

3.

Start the engine, run it at a mid-range speed for 1 minute, then stop the engine.

4.

Turn the starting switch key to the ON position and depress the brake pedal repeatedly.

q

If the brake oil pressure caution lamp does not light up even when the brake is depressed 6 times, the gas

pressure in the accumulator is normal.

q

If the brake oil pressure caution lamp lights up when the brake has been depressed 5 or less times, the

gas pressure in the accumulator has probably dropped. Please contact your Komatsu distributor to have

the accumulator inspected.

REMARK

Carry out the check within 5 minutes after stopping the engine. If the machine is left with the engine stopped, the

accumulator pressure will drop and it will be impossible to check the cause of the problem.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...