HANDLING AUTO-GREASING SYSTEM

ATTACHMENTS, OPTIONS

6-12

2.

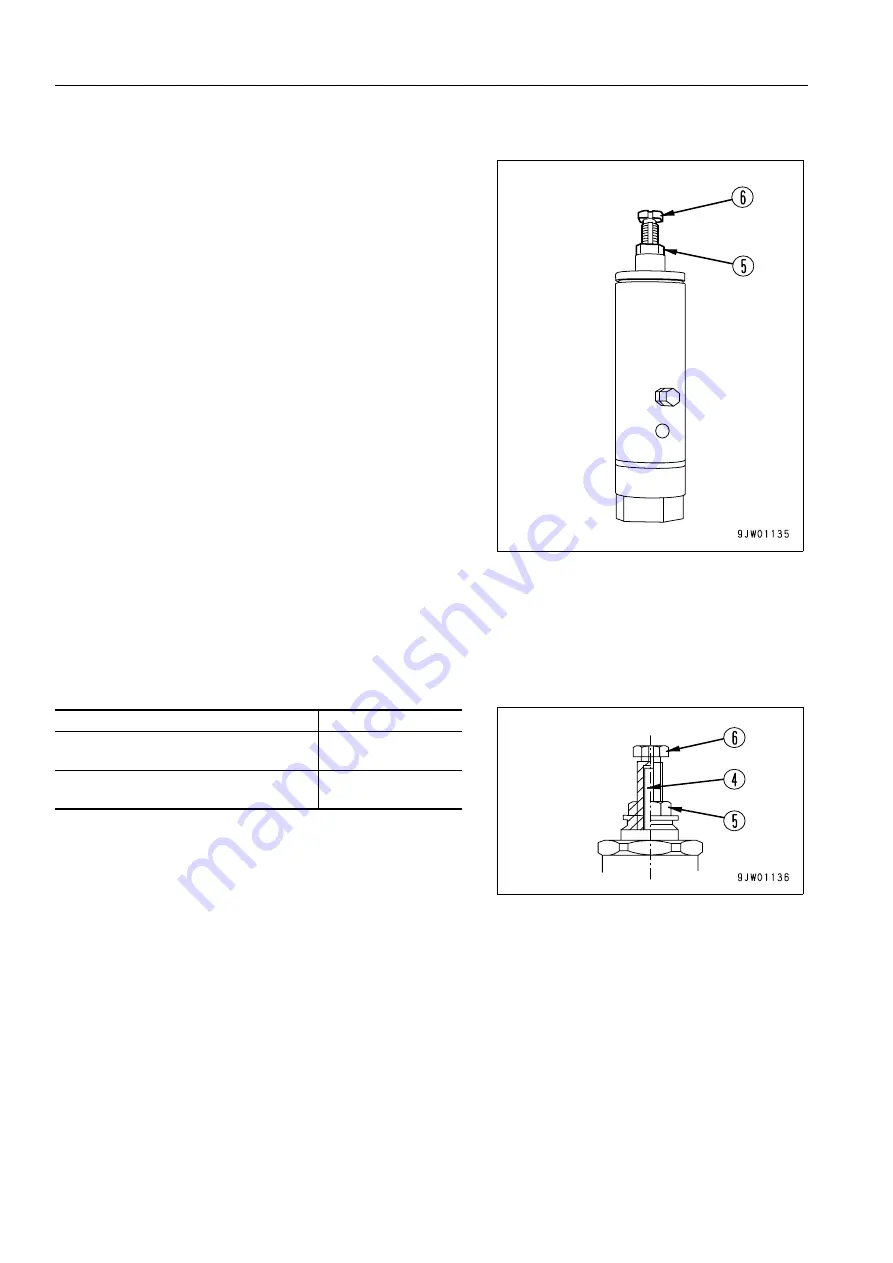

Injector (SL11)

1) The injector is operated by the pressure from the pump,

and it feeds grease of the specified quantity to the bearing.

2) To see if the injector works normally, check the operation

of indicator pin (4) on its head. If the injector is normal, the

pin is retracted first. If the pump stops and the pressure is

lost, the pin returns and it is reset for the next greasing.

3) Adjust the discharge from the injector with adjustment

screw (6) on its head.

1] To reduce the discharge, loosen lock nut (5) and turn

adjustment screw clockwise. If the adjustment screw stops

(at the stopper), the discharge is minimized.

2] If the adjustment screw is returned by 10 turns from the

fully tightened position (minimum discharge) in 1] above,

the discharge is maximized (8.2 cc/st).

After adjusting the discharge from the injector, be sure to

tighten lock nut.

4) Although the injector can be overhauled and repaired, replace it with a spare one, if possible, when it has any

trouble.

q

Discharge adjusting procedure for large-sized injector (SL-11) (Added to bucket pin)

Loosen lock nut (5) and turn adjustment screw (6) to adjust the discharge of grease made each time.

One turn between the maximum and minimum positions change the discharge by 0.82 cc.

After adjusting the discharge, be sure to tighten the lock nut.

Discharge (cc/cycle)

Turn clockwise to stopper

(Min. discharge)

0.82

Turn counterclockwise by 10 turns

from above position (Max. discharge)

8.2

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...