MAINTENANCE

SERVICE PROCEDURE

4-29

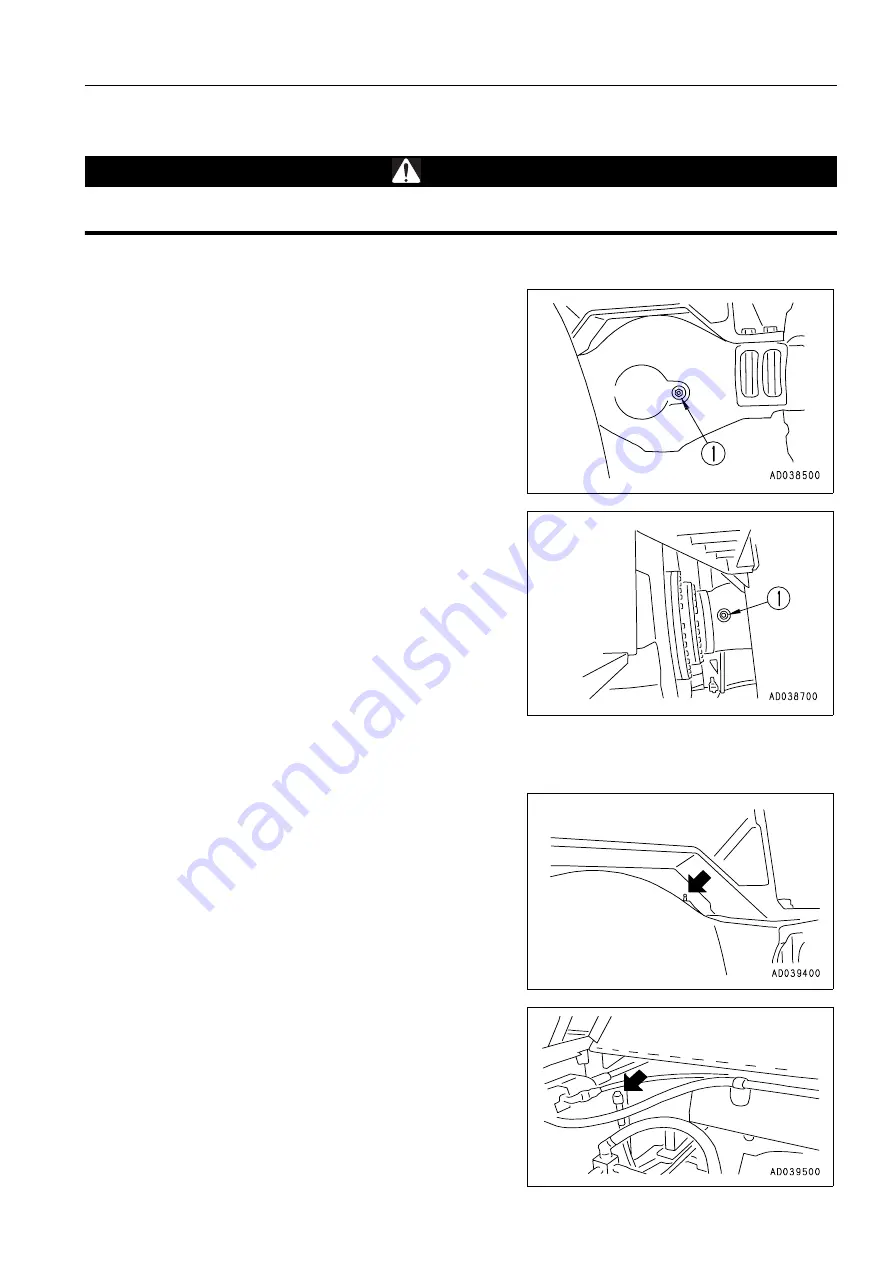

CHECK AXLE OIL LEVEL, ADD OIL

4

WARNING

The parts and oil are at high temperature immediately after the engine is stopped, and may cause burns.

Wait for the temperature to go down before starting the work.

Perform this procedure if there is any sign of oil on the axle

case.

Inspect the machine on a horizontal surface.

(If the road surface is at an angle, the oil level cannot be

checked correctly.)

1.

Stop the machine in a horizontal place.

2.

Stop the engine, then wait for the oil temperature to go

down.

3.

Remove level plug (1).

4.

Check that the oil level is near the bottom of the plug hole.

5.

If the oil is not near the bottom edge of the hole, add oil

through oil filler (F).

6.

If the oil level is correct, install level plug (1)

Tightening torque: 127 to 177 Nm (13.0 to 18.0 kgm)

CLEAN AXLE CASE BREATHER

4

1.

Stop the machine in a horizontal place.

2.

Stop the engine.

3.

Use a brush to clean off any mud or dirt from around the

breather.

4.

After removing all the mud or dirt from around the breather,

remove the breather, and soak it in flushing liquid to clean

it.

When cleaning the breather, clean the breathers at two

places (front and rear).

After removing the breather, take steps to prevent dirt or

dust from entering the mount.

5.

Install the breather.

When cleaning the breather, clean the breathers at two

places (front and rear).

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...