MAINTENANCE

SERVICE PROCEDURE

4-45

EVERY 100 HOURS SERVICE

4

Maintenance for every 50 hours service should be carried out at the same time.

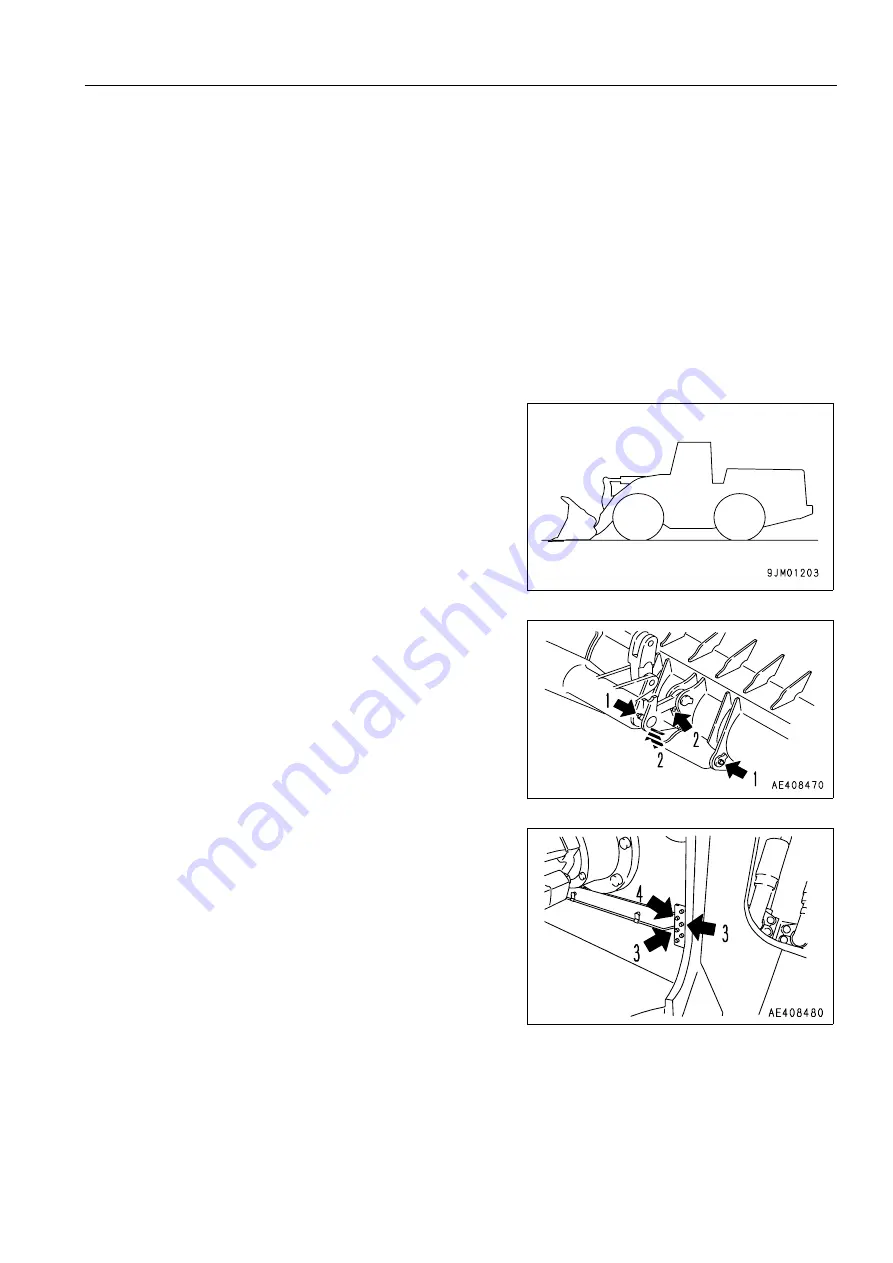

LUBRICATING

4

(Applicable for machines with no auto greasing system installed.)

NOTICE

q

In the extremely hard working conditions, grease the following pins (1) through (6) every 10 hours of

operation or daily, whichever way is deemed appropriate.

q

During the initial breaking in for a new machine, carry out ubrication every 10 hours for the first 50

hours of operation.

1.

Using a grease pump, pump in grease through the grease

fittings marked by the arrows.

2.

After greasing, wipe off any old grease that was pushed

out.

Lower the bucket to the ground and set it horizontally.

(1) Bucket pin (2 places)

(2) Bucket link pin (2 places)

(3) Lift arm hinge pin (2 places)

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...