SERVICE PROCEDURE

MAINTENANCE

4-62

REPLACE FUEL MAIN FILTER CARTRIDGE

4

WARNING

q

After the engine has been operated, all parts are at high temperature, so do not replace the filter imme-

diately. Wait for all parts to cool down before starting the operation.

q

High pressure is generated inside the engine fuel piping system when the engine is running.

When replacing the filter, wait for at least 30 seconds after stopping the engine to let the internal pres-

sure go down before replacing the filter.

q

Do not bring any fire or flame close.

NOTICE

q

Genuine Komatsu fuel filter cartridges use a special filter that has highly efficient filtering ability.

When replacing the filter cartridge, always use a genuine Komatsu part.

q

The common rail fuel injection system used on this machine consists of more precise parts than the

conventional injection pump and nozzle.

If any part other than a genuine Komatsu filter cartridge is used, dust or dirt may get in and cause

problems with the injection system. Always avoid using substitute parts.

q

When carrying out inspection or maintenance of the fuel system, pay more attention than normal to

the entry of dirt. If dirt is stuck to any part, use fuel to wash it off completely.

q

Prepare a container to catch the fuel.

q

Prepare a filter wrench

1.

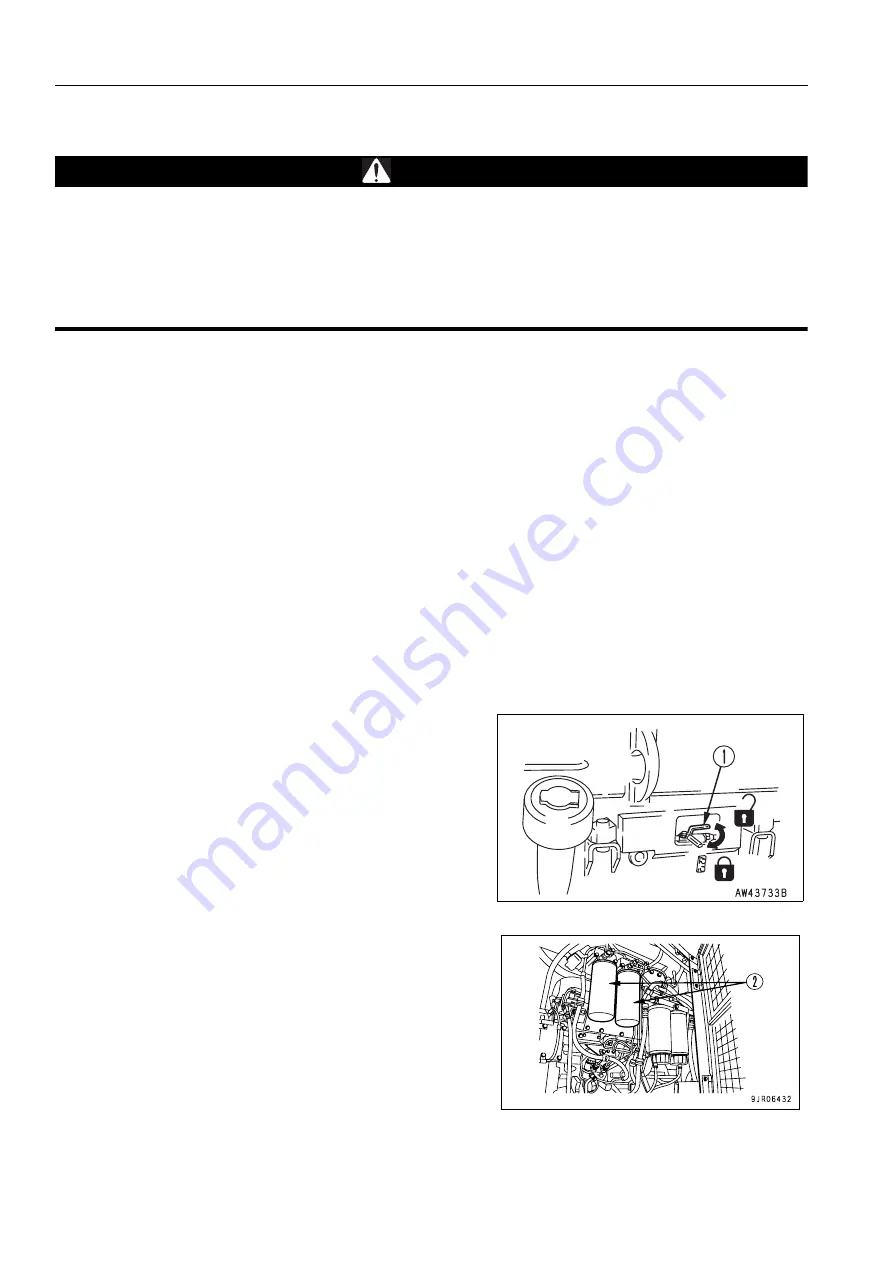

Open the side panel located on the right of the machine

and lock the open lock.

2.

Set a container under the fuel main filter cartridge to catch

the fuel.

Turn fuel stop lever (1) toward you to prevent the fuel from

dripping.

3.

Using a filter wrench, turn filter cartridge (2) counterclock-

wise to remove it.

4.

Clean the filter holder.

5.

Coat the packing surface of the filter cartridge with oil.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...