SERVICE PROCEDURE

MAINTENANCE

4-78

REPLACE BRAKE OIL TANK BREATHER

4

WARNING

q

The parts and oil are at high temperature immediately after the engine is stopped, and may cause

burns. Wait for the temperature to go down before starting the work.

q

When removing the oil filler cap, turn it slowly to release the internal pressure, then remove it.

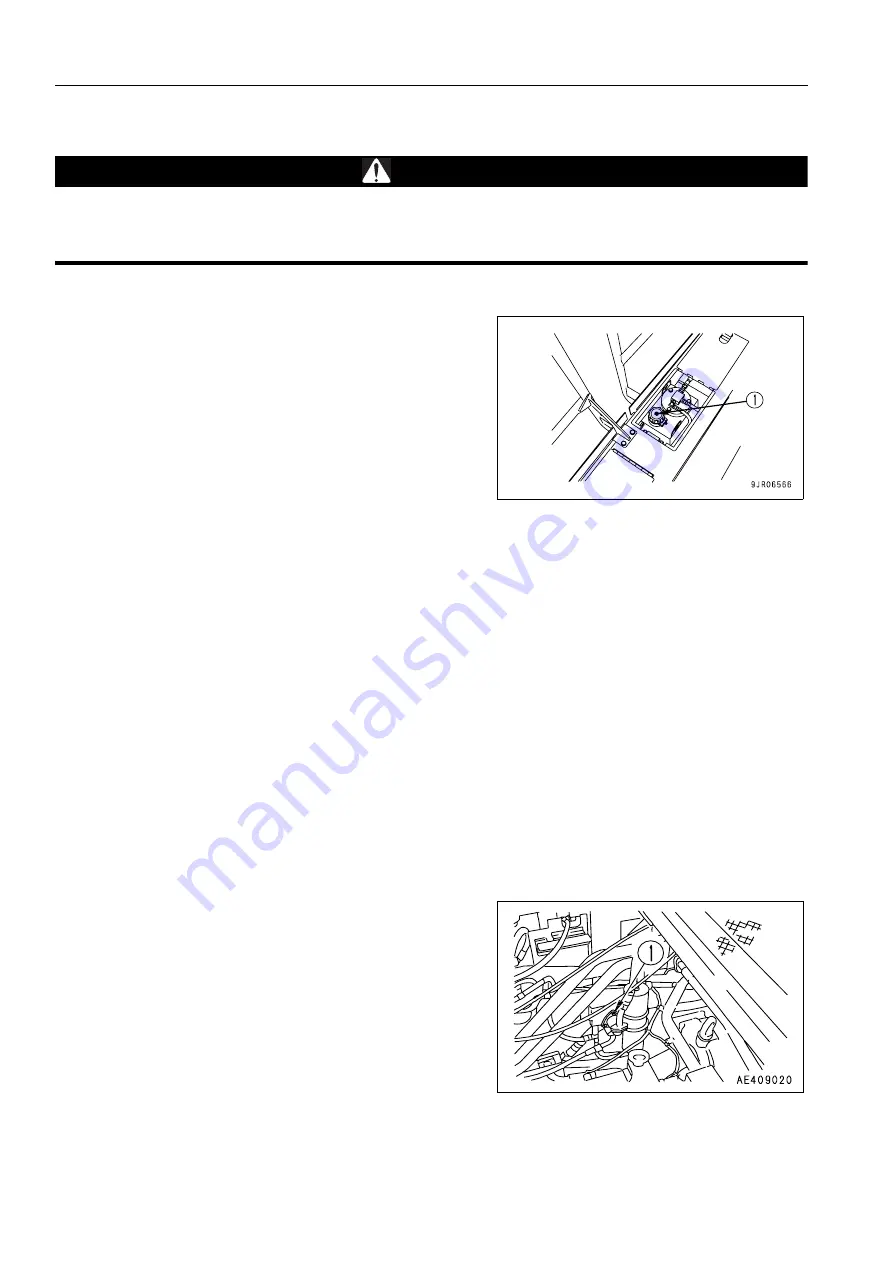

1.

Open the cover on top of the platform on the left side of the

cab.

2.

Loosen bolt (1) at the top of the cap.

3.

Remove the cap and take out the element.

4.

Coat O-ring of the new element with grease, then install.

5.

Align the cap with indent or protrusion of the body, then

tighten bolt (1).

6.

Close the cover on top of the platform on the left side of the

cab.

REPLACE ELEMENT IN AIR CONDITIONER RECIRCULATION AIR FILTER, FRESH AIR

FILTER

4

Remove both the recirculation air filter and fresh air filter in the same way as when cleaning, and replace them with

new parts.

For details of cleaning the recirculation air filter, see “CLEAN ELEMENT IN AIR CONDITIONER RECIRCULA-

TION FILTER (4-53)“.

For details of cleaning the fresh air filter, see “CLEAN ELEMENT IN AIR CONDITIONER FRESH AIR FILTER (4-

48)“.

CLEAN PPC CIRCUIT STRAINER

4

1.

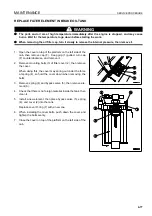

Remove 3 bolts (1) of the PPC circuit strainer.

2.

Remove the strainer case and pull out the strainer, then

wash the strainer with clean diesel fuel.

3.

Install the strainer in the strainer case, and install it with

bolts (1).

4.

Put bucket control lever in TILT position and lift arm control

lever in FLOAT position, and after cylinder reaches stroke

end, keep in that position for one minute.

5.

Put bucket control lever in DUMP position and lift arm con-

trol lever in RAISE position, and after cylinder reaches

stroke end, keep in that position for one minute.

6.

Bleed the air from the hydraulic circuit. For details, see “BLEEDING AIR FROM PPC CIRCUIT (4-36)“.

Summary of Contents for WA800-3E0

Page 2: ......

Page 3: ...FOREWORD 11...

Page 27: ...SAFETY SAFETY LABELS 2 5 LOCATION OF SAFETY LABELS 2...

Page 66: ...GENERAL VIEW OPERATION 3 4...

Page 84: ...EXPLANATION OF COMPONENTS OPERATION 3 22 SWITCHES 3...

Page 224: ...TROUBLESHOOTING OPERATION 3 162...

Page 309: ...SPECIFICATIONS 15...

Page 330: ...HANDLING MACHINES EQUIPPED WITH VHMS ATTACHMENTS OPTIONS 6 20...

Page 331: ...INDEX 17...

Page 332: ...INDEX 7 2...

Page 335: ...COLOPHON 18...