7

I

NCREASED

R

ELIABILITY

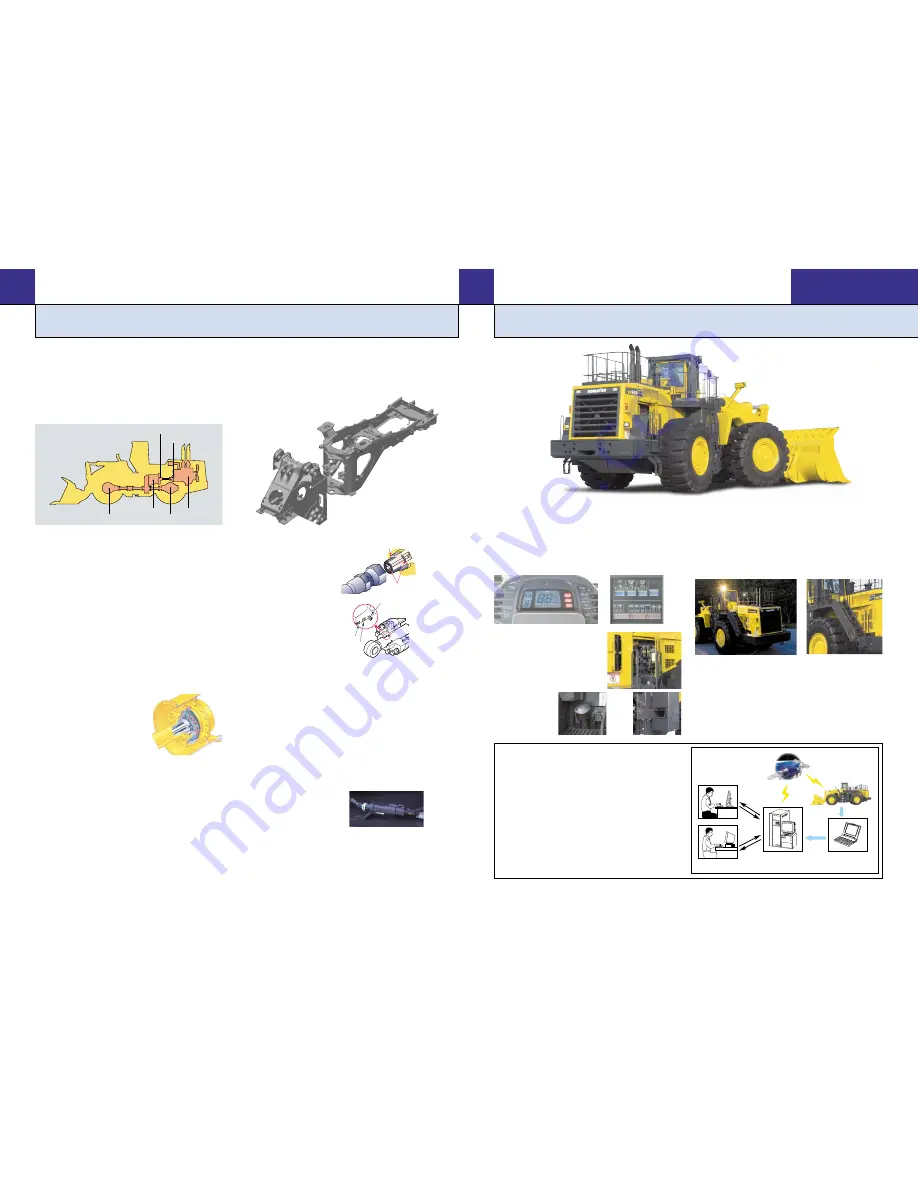

WHEEL LOADER

WA900

-3E0

W

H E E L

L

O A D E R

E

ASY

M

AINTENANCE

6

Komatsu Components

Komatsu manufactures the engine, torque converter,

transmission, hydraulic units, electric parts, on this wheel

loader. Komatsu loaders are manufactured

with an integrated production system under a strict quality

control system.

Engine pre-lube System (optional)

Durability of the engine is achieved by raising the engine oil

pressure before starting the engine. When the operator turns

the key, the pre-lubrication pump sends oil from the engine

oil pan to the engine oil filter and raises the pressure of that

oil to the set pressure. Then, the starting motor rotates to

start the engine.

Maintenance-Free Braking System

Service brakes employ two hydraulically-actuated

independent circuits which are adjustment-free, fully-sealed,

wet disc units, preventing intrusion of dirt and dust. Since the

brake system does not use air, it provides many features

such as absence of condensation, dependable braking even

in cold conditions, no need for

drainage, and rust free piping.

What's more, charging time after

engine starting is drastically

shortened and pedal depressing

effort is reduced.

High-rigidity Frames and Loader Linkage

The front and rear frames and the loader linkage have more

torsional rigidity to secure resistance against increased

stress. Frame and loader linkage are designed to

accommodate actual working

loads, and simulated

computer testing proves

its strength.

Flat Face-to-Face O-Ring Seals

Flat face-to-face O-ring seals

are used to securely seal

hydraulic hose connections

and to prevent oil leakage.

In addition, buffer rings are

installed to the head side of

the all-hydraulic cylinders to

lower the load on the rod

seals and maximize

reliability.

Cathion Electrodeposition Primer Paint/

Powder Coating Final Paint

Cathion electrodeposition paint is applied as a primer

paint and powder coating is applied as topcoat to the

exterior sheet metal parts. This process results in a

durable paint finish, even in the most severe environments.

Some external parts are made of plastic providing long life

and high impact resistance.

Sealed DT Connectors

Main harnesses and controller connectors are equipped

with sealed DT connectors

providing high reliability, water

resistance and dust resistance.

buffer rings

dust seal

rod packing

nipple

hose

O-ring

Simple Checks, Easy Maintenance

The main monitor and the maintenance monitor (EDIMOS II)

are neatly arranged on the instrument panel for a quick, clear

reading of machine functions at all times. The main monitor

also has a diagnostic function.

Main monitor

Maintenance monitor

Large Side Door

Right side door is easy to open

and provides accessibility for

maintenance.

Fuel Tank Cap

with Mud Cover

and Large Tool

Box

Rear Access Stairs

For the purpose of boarding and exiting machine, rear

access stairs with handrail is provided. The step width,

clearance, and the step angle have been designed for

climbing both up and down. A step light provides light for

night boarding.

Auto-Greasing System (optional)

The periodic lubrication points, except for drive shaft, are

greased automatically according to a preset amount and

interval. Quick-change grease canisters make replacement

easy and clean.

VHMS (Vehicle Health Monitoring System) (optional)

VHMS is a management system for large equipment for

use in mining, which enables detailed monitoring of fleet

via satellite communications. Komatsu and distributors can

analyze “vehicle health” and other operating conditions and

provide the information to job site using the internet from a

remote location on a near-real time basis.

Satellite

communication(option)

Personal Computer

terminal

(for downloading data)

WebCARE Server

Komatsu

distributors

KOMATSU

Customer

job site

Photo may include optional equipment.

WA900

-3E0

Rear axle

Engine

Torque converter

Damper

Transmission

Front axle

Tool box

Fuel tank cap