UAB KOMFOVENT we reserve the right to make changes without prior notice

RHP-C5.1_21-01

33

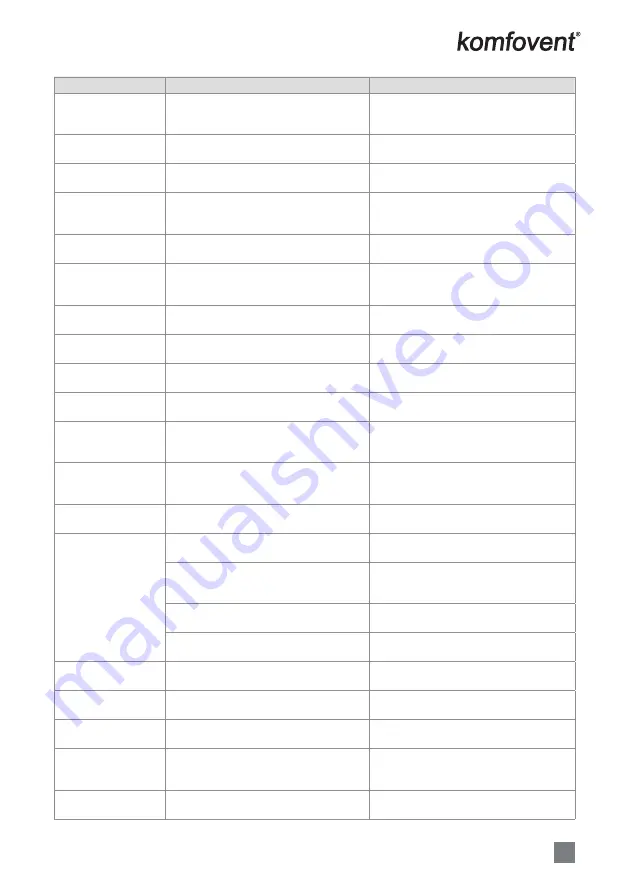

Message

Possible cause

Elimination

Return water tempera-

ture low

Return water temperature of the heater

dropped below the permissible limit.

Check the status and operation of the circula-

tion pump, heating system and mixing valve

actuator.

Internal fire alarm

Fire danger in the ventilation system.

Check the ventilation system. Find the

source of the heat.

External fire alarm

A fire signal has been received from the fire

signalization system of the building.

Delete alarm message and restart the unit

when the fire signal disappears.

External stop

A signal from an external device (switch,

timer, or sensor) has been received.

As soon as the auxiliary device is switched

off, the unit will operate in the previous

mode.

Heat exchanger failure Blocked or not rotating rotor, by-pass

damper failure.

Check the rotor drive, replace the belt or

check the by-pass channel operation.

Heat exchanger icing

Icing may form under a low outdoor tem-

perature and high room humidity.

Check the operation of the rotation heat

exchanger drive or the air bypass damper

of the plate heat exchanger.

Low supply air tem-

perature

The heating equipment fails to operate or

its capacity is insufficient.

Check the heating equipment.

High supply air tem-

perature

The heating equipment is not controllable

(mixing valve or contactor is blocked).

Check the heating equipment.

Electric heater

overheat

The emergency overheating protection of

the electrical heater has actuated.

Protection can be reset only by pressing the

RESET press-button on the heater.

Evaporator air tem-

perature sensor failure

The evaporator air temperature sensor is

not connected or broken.

Check connections of the sensor or replace

the sensor.

Evaporator icing

The evaporator is iced over due to exces-

sively high humidity content in the exhaust

air and low outdoor temperatures.

Check the operation of the evaporator

defrost system.

High pressure on

compressor

Compressor system operated in an over-

load mode as a result of too high tempera-

ture in the condensing unit.

Indentify the cause and eliminate it.

Low pressure on

compressor

Compressor system is leaky or the

amount of refrigerant is insufficient.

Indentify the cause and eliminate it.

Compressor failure

No power supply.

Check supply voltage on the circuit breaker

and/or make sure whether it is on.

Supply voltage mismatches.

Check that the supply voltage is on all three

phases, if necessary, swap the two phase

conductor positions.

Compressor motor failure.

Check the compressor motor and replace it

if necessary.

Compressor drive failure.

Check the operation of the compressor drive

and replace it if necessary.

Supply fan drive

failure

A fault signal has been received from the

supply fan drive.

Check the supply fan drive and its messages.

Supply fan drive

overload

The supply fan drive is overloaded.

Check the condition of the supply fan drive

and its cooling.

Supply fan motor

failure

The supply fan is broken.

Check the supply fan and replace it if neces-

sary.

Supply fan motor

overload

The supply fan is overloaded.

Check the condition of the supply fan and

make sure that the resistance of the ventila-

tion system is not exceeded.

Exhaust fan drive

failure

A fault signal has been received from exhaust

fan drive.

Check the exhaust fan drive and its messages.