EN

UAB KOMFOVENT we reserve the right to make changes without prior notice

RHP-C5.1_21-01

34

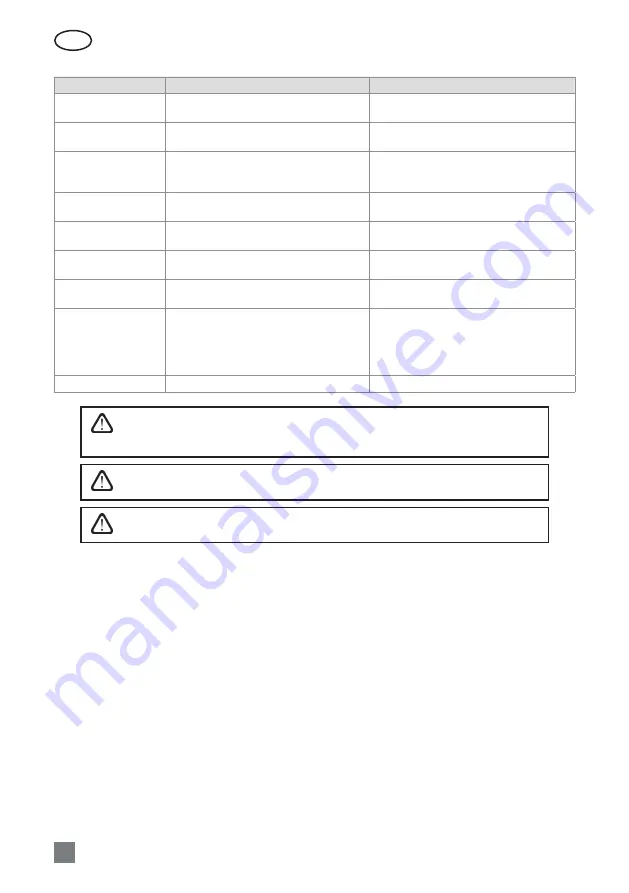

Message

Possible cause

Elimination

Exhaust fan drive

overload

The exhaust fan drive is overloaded.

Check the condition of the exhaust fan drive

and its cooling.

Exhaust fan motor

failure

The exhaust fan is broken.

Check the exhaust fan and replace it if

necessary.

Exhaust fan motor

overload

The exhaust fan is overloaded.

Check the condition of the exhaust fan and

make sure that the resistance of the ventila-

tion system is not exceeded.

Rotor drive failure

A fault signal has been received from the

rotor drive.

Check the rotor drive and its messages.

Rotor drive overload

The rotor drive is overloaded.

Check the condition of the rotor drive and

its cooling.

Rotor motor failure

The rotor motor is broken.

Check the rotor motor and replace it if neces-

sary.

Rotor motor overload

The rotor motor is overloaded.

Check the condition of the rotor motor and

make sure that the rotor is not blocked.

Communication error

No communication with the internal com-

ponents of the air handling unit (controller

extension modules, frequency converters,

fans, etc.) or one / several of them are

broken.

Check internal connections and functioning

of separate components.

Controller failure

Main controller module fault.

Replace the main controller.

The emergency protection of the electrical heater against overheating can be

reset with the RESET button only if the cause of the overheating of the heater has

been clarified and eliminated.

If the unit is shut down and a failure text message is shown on the control panel,

the fault must be eliminated!

Before performing any jobs inside the unit make sure that the unit is stopped and

disconnected from the electrical power supply.

After failure has been eliminated and power supply connected the error messages should be de-

leted. However if the failure has not been eliminated, unit either starts operating and after some time it

stops again, or it does not operate and failure message is indicated.