24

UAB KOMFOVENT we reserve the right to make changes without prior notice

RHP PRO_22-01

EN

Pipes of water heater and cooler are connected to a water mixing unit (PPU) that supplies hot/cold water from the build-

ing’s water system. Heat exchangers for direct evaporation (DX) coolers/heaters are factory-filled with nitrogen gas. Before

connecting a heat exchanger to a refrigerant system, nitrogen gas is discharged through a valve which is then cut off and

heat exchanger connections are soldered to a pipeline. Coils for water or DX coolers are fitted with condensate trays to which

a siphon and drainage piping must be connected (see Chapter “Connection of a Condensate Drain”).

Electrical heater sections require a separate power supply.

All connections to the heating or cooling system piping and mains must be performed by a qualified

specialist.

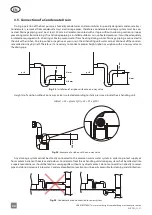

Fig. 20.

Connection of sleeves

When connecting sleeves of water heaters/coolers, use two pipe wrenches to secure sleeves, otherwise they will be dam-

aged. If water is used in the heater, for frost protection return water temperature sensor (B5) must be installed on the return

water pipe as close to the heater as possible. It can be screwed

1

into a special opening or fixed with a strap on the pipe. Fix

the sensor in a way that its metal part has good contact with a surface of the pipe. The sensor must be thermally insulated

so that the room temperature does not distort water temperature measurements.

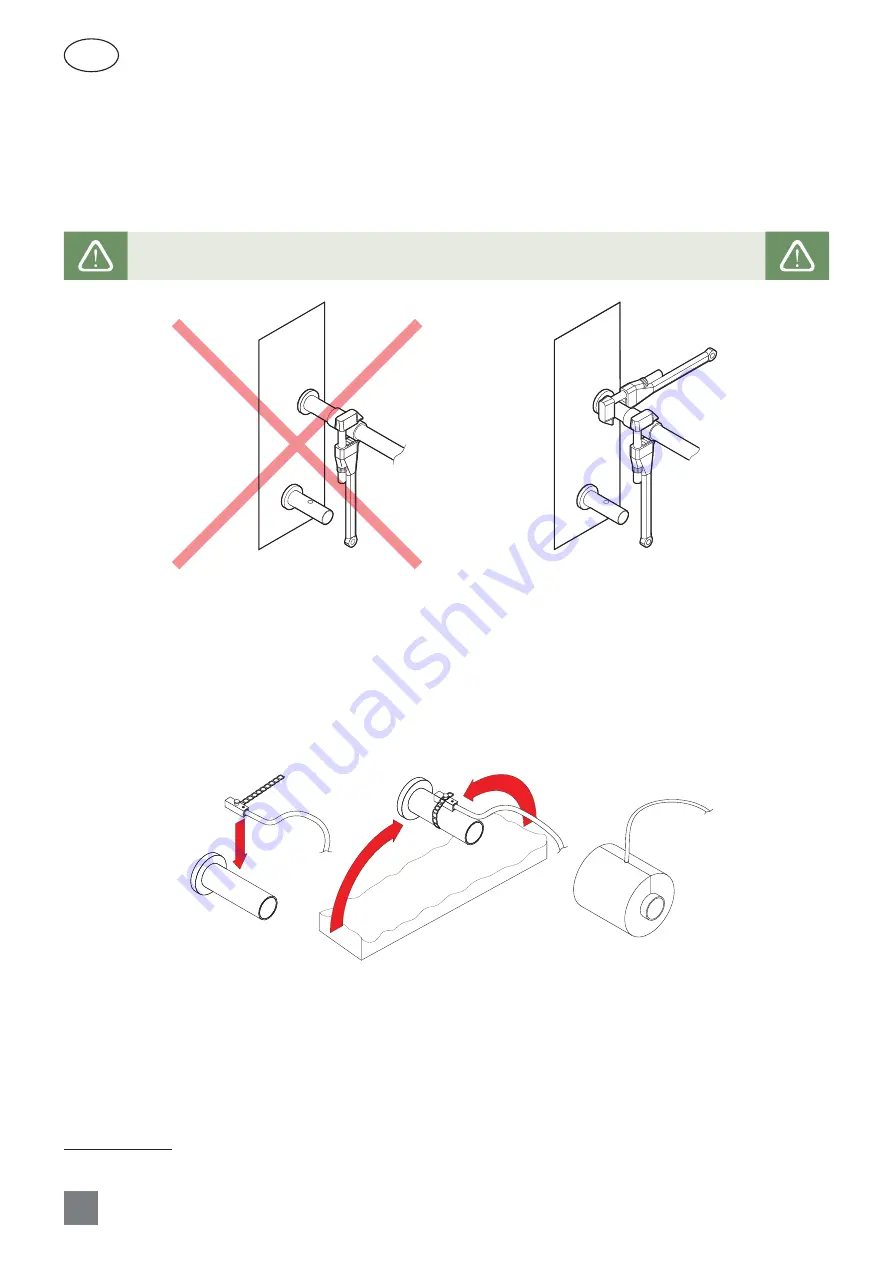

Fig. 21.

Installation of a surface-mounted return water temperature sensor

2

1

Depending on the order.

2

Depending on the order.