SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVA60 M / UVA120 M installation manual 21-01

20

EN

5.

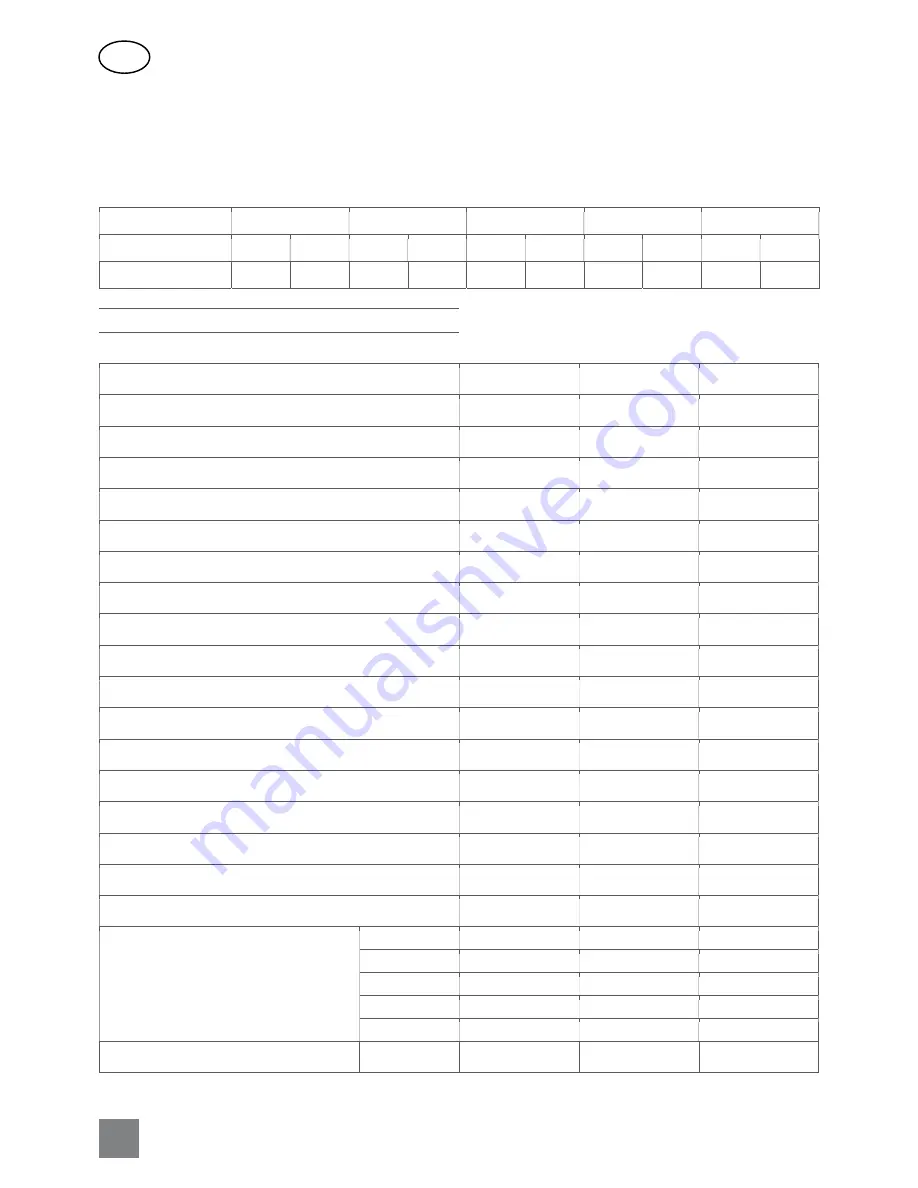

PERIODICAL INSPECTIONS

It is a mandatory requirement of EN 15650 standard that all fire dampers must be checked at least twice a year.

Below is

Komfovent recommended maintenance inspection checklist.

Year of inspection

Year 1

Year 2

Year 3

Year 4

Year 5

Date of inspection

01.01.21

Inspected by

Installation date:

Checked by / date:

RECORDS OF THE FIRE DAMPER

Accepted by / date:

PERIODICAL INSPECTIONS

Fire damper ref. No.

FD 25

Location

Server room 121

Damper type and size

UVA120M-200

Mounted in wall (w) or slab (s) thickness

W100

Access to the damper compliant

Yes

Installation in acc. to manufacturer’s instructions

Yes

Correct operation of the fire damper

Yes

Damper cleanness (accumulated dust, grease)

No

Lubricate all moving Parts (done/not done)

Yes

Damper condition (corrosion, rust)

No

Fusible link or thermosensor was replaced

No

Damages or modifications

No

Blade and sealing material are undamaged

Yes

Wiring of the end switches is undamaged and connected

Yes

Wiring of the actuator is undamaged and connected

NA

Pass / fail blade drop test

Pass

End switches indicate blade closing

Yes

Fire damper left in OPEN position

Yes

Year of inspection

1

x

2

3

4

5

Comments

Summary of Contents for UVA120 M

Page 1: ...2021 ...