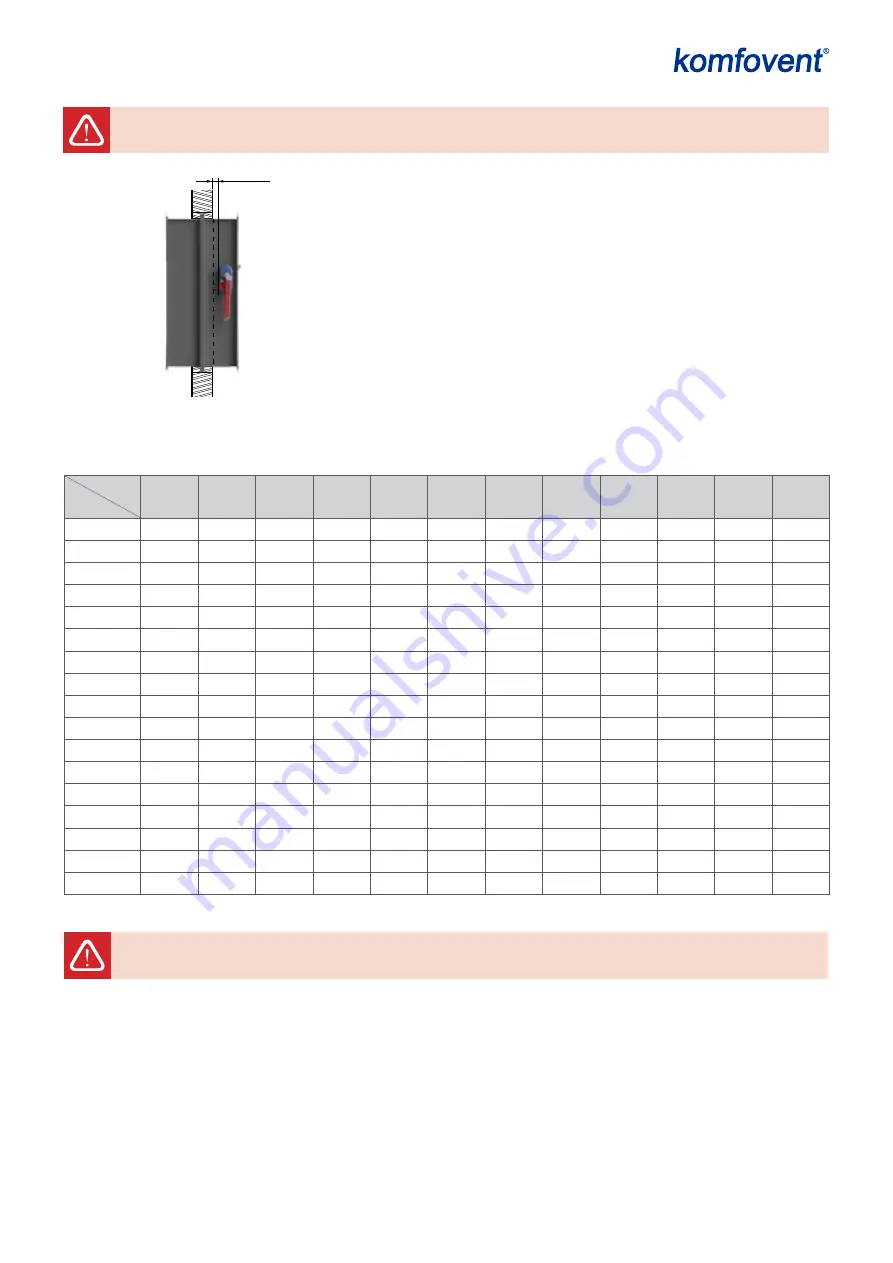

8 ... 10 mm

SIA KOMFOVENT reserves the right to make changes without prior notice

Fire damper UVS120 H (Two-Bladed design) ∙

I

nstallation manual ∙ 21-01

9

1050

1100

1150

1200

1250

1300

1350

1400

1450

1500

1550

1600

200

21.1

21.9

22.5

23.3

23.9

24.7

25.3

26.1

26.7

27.5

28.1

28.8

250

23.1

23.9

24.6

25.3

26.1

27.1

27.7

28.5

29.3

30.0

30.8

31.6

300

25.0

25.9

26.6

27.3

28.3

29.5

30.0

32.9

33.8

34.6

35.4

36.2

350

27.0

27.9

28.7

31.9

32.8

33.7

34.6

35.4

36.3

37.2

38.1

39.0

400

31.1

32.1

33.0

34.0

34.9

36.0

36.9

37.9

38.8

39.8

40.7

41.7

450

33.1

34.2

35.1

36.2

37.2

38.3

39.3

40.3

41.3

42.4

43.3

44.4

500

35.0

36.2

37.2

38.4

39.4

40.5

41.6

42.7

43.8

44.9

45.9

47.1

550

37.0

38.2

39.3

40.5

41.6

42.8

43.9

45.0

46.2

50.6

51.8

52.9

600

38.9

40.1

41.3

42.6

43.7

45.0

49.4

50.7

51.8

53.1

54.3

55.5

650

40.9

42.1

43.4

44.8

49.7

51.0

51.7

53.1

54.3

55.6

56.9

58.1

700

42.8

44.1

48.7

50.1

51.4

52.8

54.0

55.5

56.7

58.1

59.4

60.8

750

44.8

49.3

50.7

52.1

53.5

54.9

56.3

57.8

59.2

60.6

62.0

63.4

800

49.8

51.3

52.7

54.2

55.7

57.2

58.6

60.2

61.6

63.1

64.5

66.0

850

51.5

53.1

54.7

56.2

57.8

59.2

60.9

62.6

64.1

65.6

67.1

68.7

900

53.2

54.9

56.5

58.1

59.8

61.2

63.2

65.0

66.5

68.1

69.6

71.3

950

55.0

56.7

58.4

60.2

61.9

63.3

65.5

67.3

69.0

70.6

72.2

74.0

1000

56.7

58.6

60.4

62.2

64.0

65.4

67.8

69.7

71.4

73.1

74.7

76.6

B

nom

H

nom

Note: for installation of a damper into a wall axle of the blade should be positioned horizontally only! Blade of a damper always has to be

placed INSIDE the supporting construction. Main mechanism can be used as a guide to find right damper’s position:

Recommended distance between supporting construction (wall or

ceiling) edge and main mechanism of the fire damper is 8 to 10 mm.

It is extremely important that the blade is positioned into the

supporting construction, if possible closer to its center.

Red duct tape can be used as a guide to identify fire damper’s blade

position.

It is important to select only appropriate fastening for fire damper supporting based on its weight, kg:

Please be advised, that after installation of the damper periodical inspections will be held in accordance with p. 4 and it is necessary to

ensure access to the main mechanism of a fire damper.