35

Combination

E

F

G

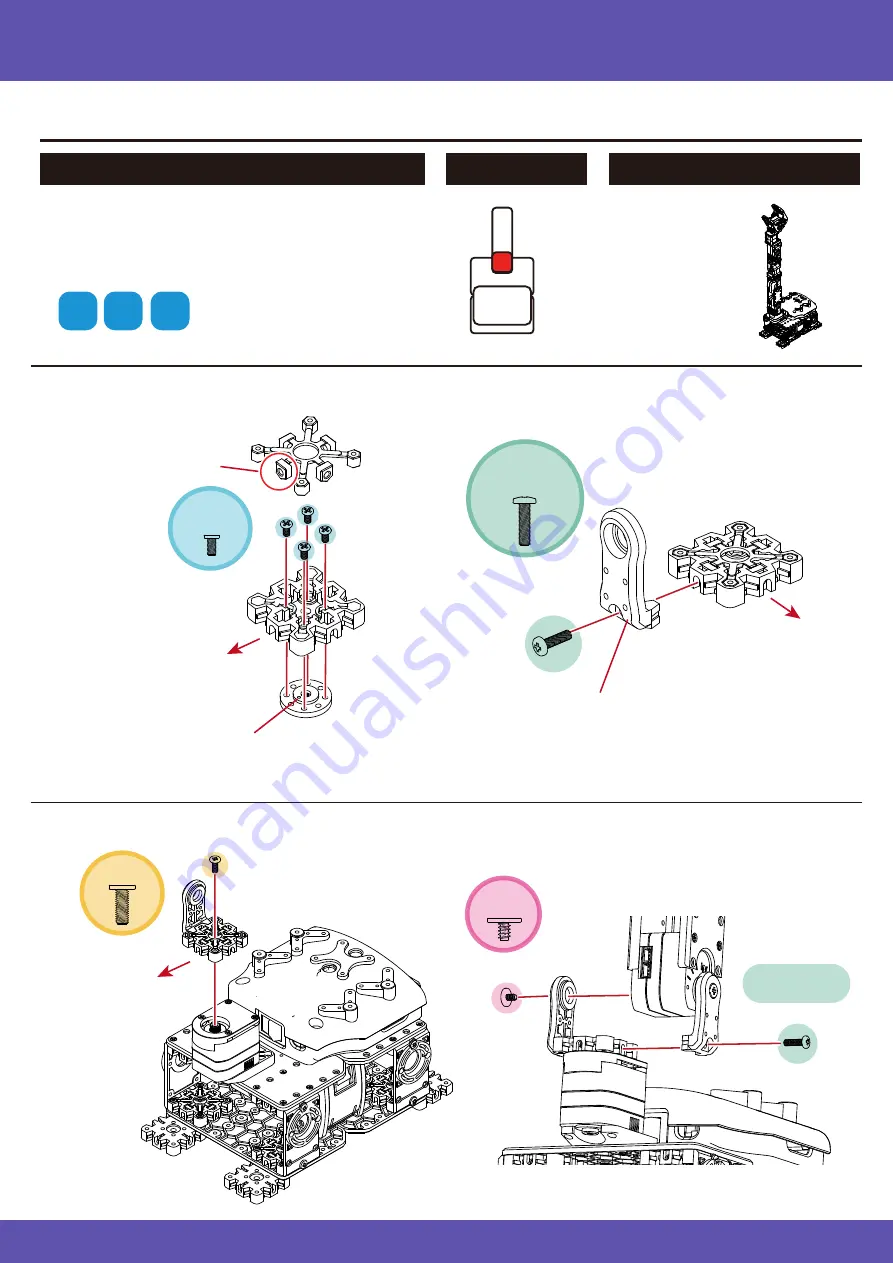

◯Joint base x1

◯Joint nut x1

◯Bottom arm 3300-26 x1

◯Cable guide X x1

◯Horn B x1

◯M2 ー 4 x4

◯M2 ー 6 x1

◯M2.6 ー 10 x2

◯M3 ー 8 x1

◯2.6 ー 4 x1

◯ZH Connection cable 2

120mm x1

160mm x1

④

③

2.6 ー 4

M2.6 ー 10

M2 ー 4

x4

①

②

Joint nut

Bottom arm 3300-26

Joint base

Horn B

Make sure the arm is installed

so that the origin faces the front.

Front

Front

Front

M2.6 ー 10

M3 ー 8

*It would be helpful to

mark the origin side

with a marker, etc.

*The origin side can

be cut to mark it.

■

Atach the arm.

Assemble part

Assembly parts completed

Parts used

Parts Combination 1

Joining

KXR-A5

Summary of Contents for KXR KXR-A5

Page 58: ......