5

No.03146 No.03147(6pcs)

KRS-3302 ICS

x 11

No.03115 No.03116(6pcs)

KRS-3301 ICS

/

x4

x4

x2

x4

x2

x4

E

No. 02304

No. 02304

No. 02303

No. 02303

No. 02302

No. 02302

x4

x1

x2

x2

x2

x1

x1

x1

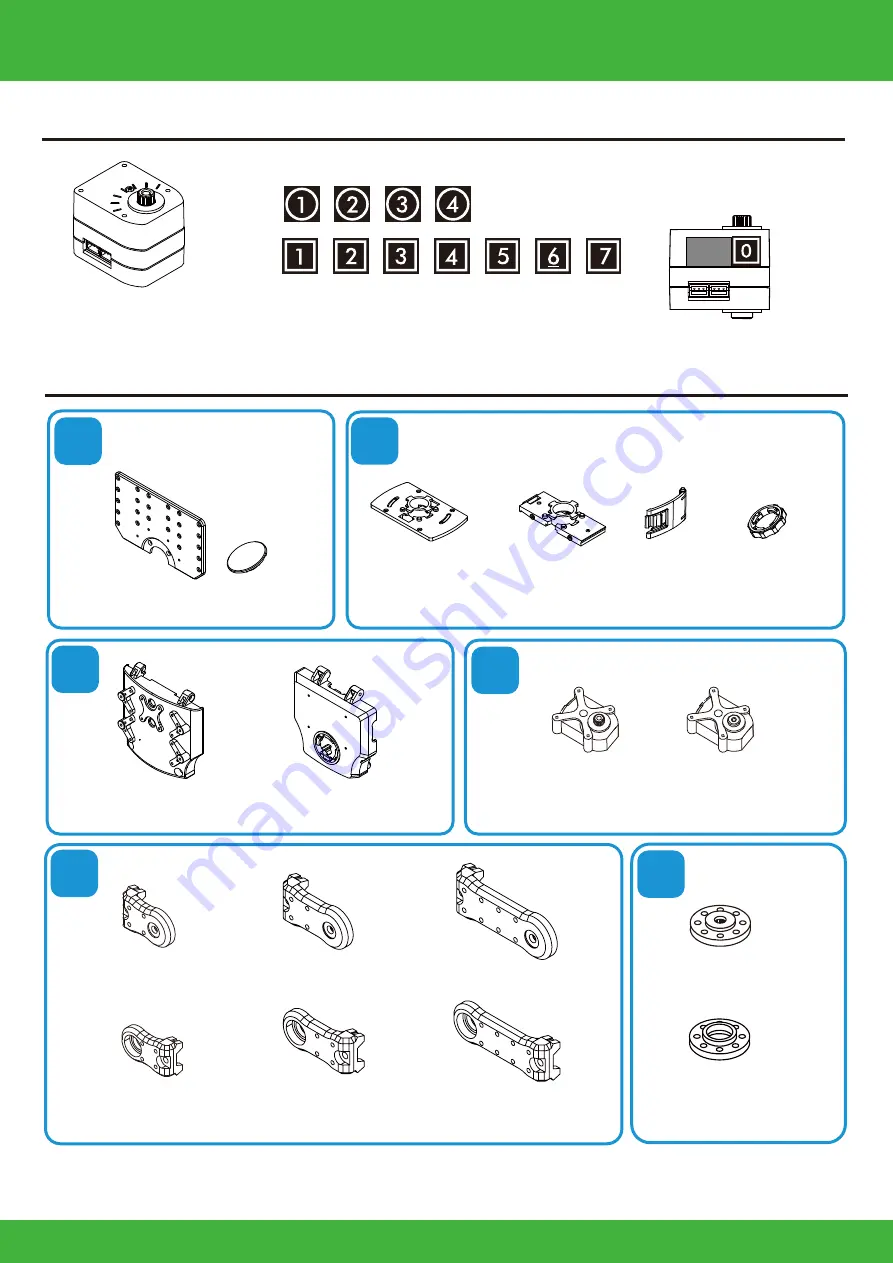

A

B

C

No. 02313

No. 02313

No. 02312

No. 02312

No. 02313

No. 02311

No. 02313

No. 02311

x1

x1

D

No. 02309

No. 02309

F

x2

x3

No. 02157

No.02159

Example of ID sticker

application

■

Frame Parts

*There may be more parts included in the set than the number used.

*No. xxxxx is the option part number. Use this number for searches and inquiries.

■

Servo

Upper Arm 3300-26

Bottom Arm 3300-26

Upper Arm 3300-26

Bottom Arm 3300-26

Upper Arm 3300-38

Bottom Arm 3300-38

Body Panel

Lock Ring Cap

Lock Ring

BT Box Plate

BT Side Plate BT Hatch

Back Pack Cover

Back Pack Base

Small Diameter

Horn C

Dummy Servo

-Upper

Dummy Servo

-Bottom

Small Diameter

Horn B

Prior to Assembly

List of Parts Used (1)

KXR-L4N

Summary of Contents for KXR-L4N

Page 42: ...42 Complete Assembly completed KXR L4N ...

Page 65: ......