413764/B

47

1

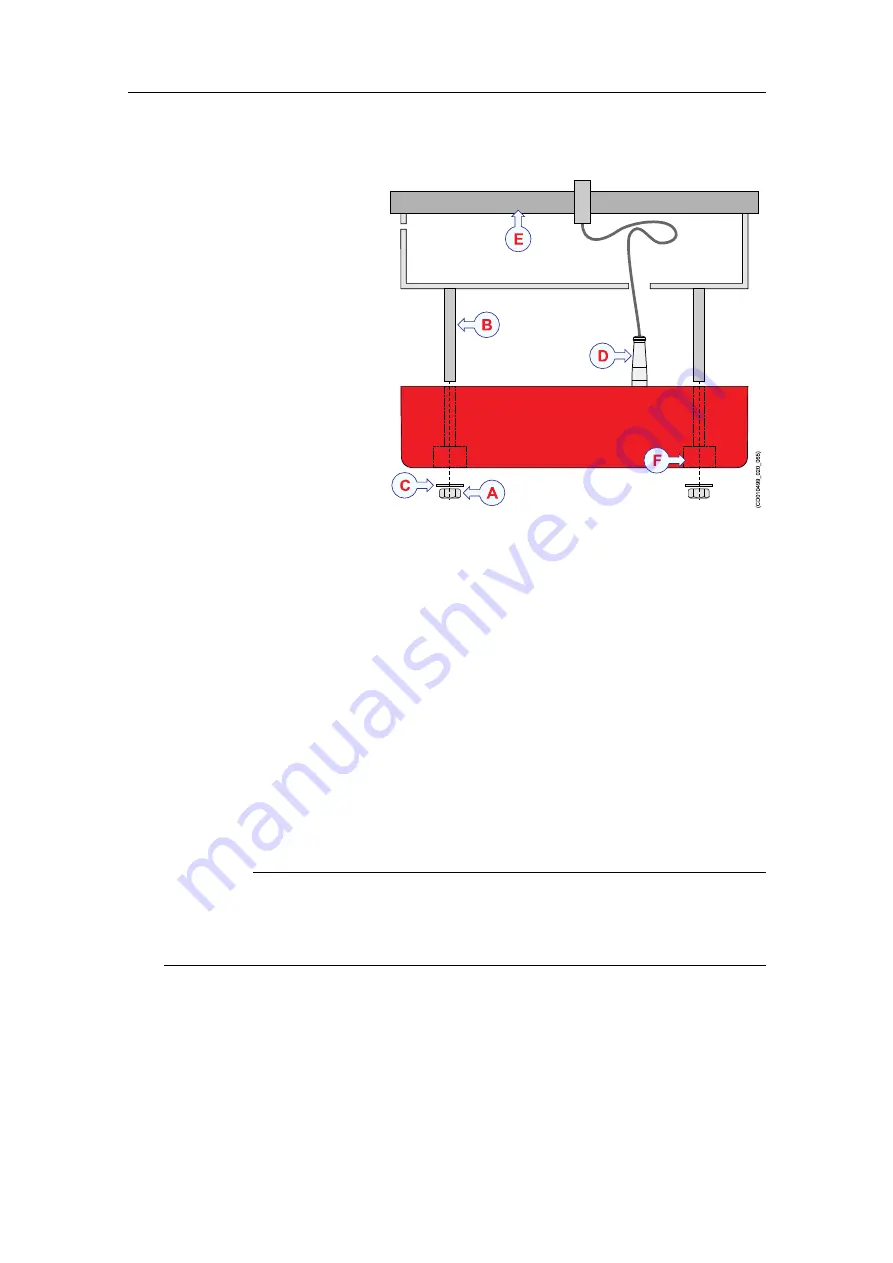

Nut

2

Threaded rod with suitable

diameter and length,

welded to the bottom of

the fairing

3

Washer

4

Transducer cable

5

Hull

6

Fill with suitable filling

compound (putty) to

reduce flow noise

Procedure

1

Lift the transducer up into

is location, and align the

holes on the transducer

with the threaded rods welded to the fairing.

Observe the direction of the transducer. The "forward" marking must point towards

the bow of the vessel!

2

Push the transducer in place.

3

Fasten the two nuts on the end of each threaded rod.

Use Loctite 290 to secure the bolts.

4

Fill the two bolt holes in the transducer with a suitable filling compound (putty),

and smooth out the surface of the transducer face.

Any obstructions, cracks, dents or unevenness on the transducer face may cause

flow noise.

5

When the transducer has been fastened, inspect the plating around the transducer

face.

Important

Make sure that the surface of the transducer face, as well as the plating and putty

around the transducer is as even and smooth as possible. Obstructions on these

surfaces will create problems with turbulent flow, and may cause noise.

6

If required, allow the relevant maritime authority and/or classification society to

inspect and approve the transducer installation.

Summary of Contents for EA640

Page 62: ...62 413764 B 388697 WBT outline dimensions EA640 Installation Manual ...

Page 63: ...413764 B 63 Drawing file ...

Page 64: ...64 413764 B 400930 WBT Cabinet outline dimensions EA640 Installation Manual ...

Page 65: ...413764 B 65 Drawing file ...

Page 66: ...66 413764 B EA640 Installation Manual ...

Page 67: ...413764 B 67 Drawing file ...

Page 93: ......

Page 94: ... 2018 Kongsberg Maritime ...