Summary of Contents for EA640

Page 62: ...62 413764 B 388697 WBT outline dimensions EA640 Installation Manual ...

Page 63: ...413764 B 63 Drawing file ...

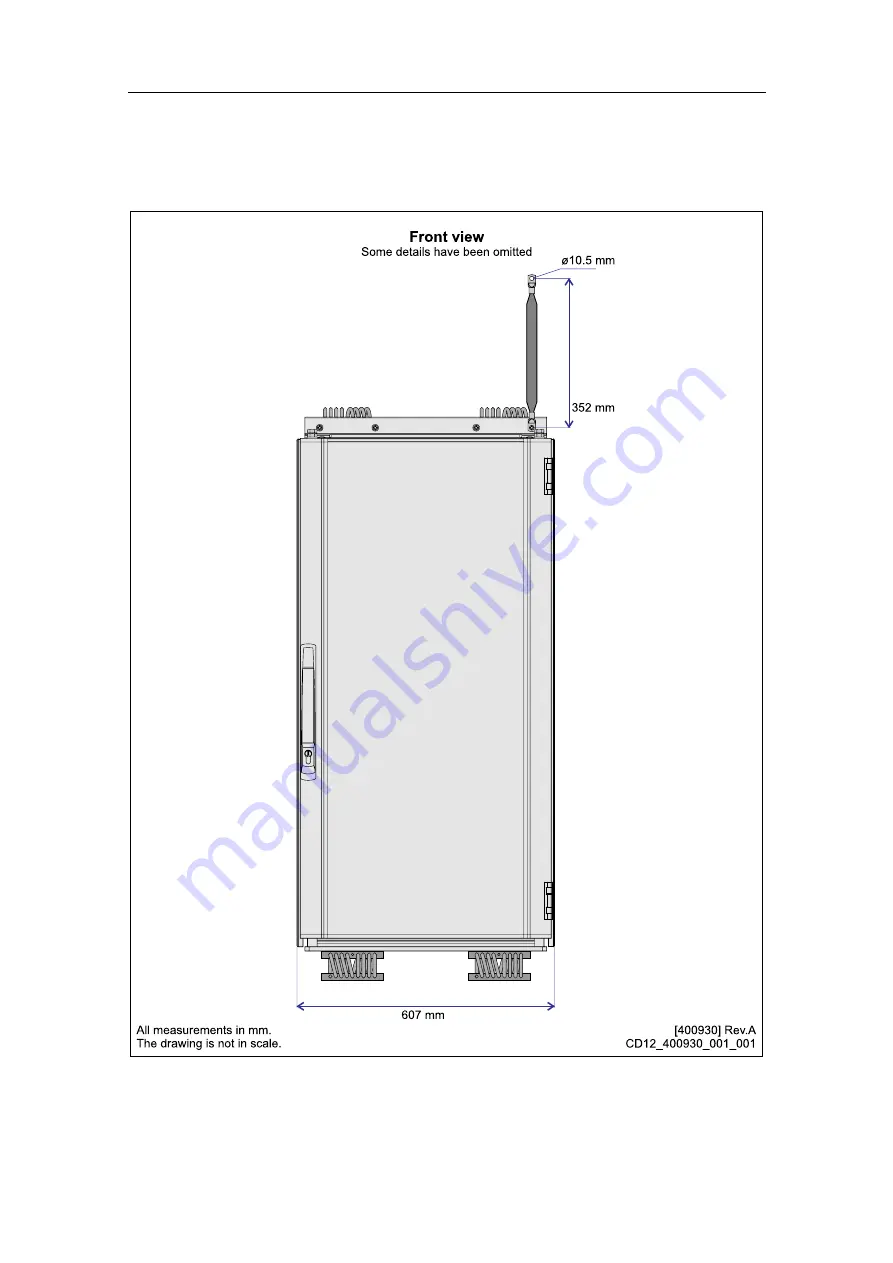

Page 64: ...64 413764 B 400930 WBT Cabinet outline dimensions EA640 Installation Manual ...

Page 65: ...413764 B 65 Drawing file ...

Page 66: ...66 413764 B EA640 Installation Manual ...

Page 67: ...413764 B 67 Drawing file ...

Page 93: ......

Page 94: ... 2018 Kongsberg Maritime ...