Summary of Contents for Flexview

Page 1: ...Installation Manual Flexview Multibeam Sonar ...

Page 2: ......

Page 8: ...6 922 20207011 1 0 Flexview ...

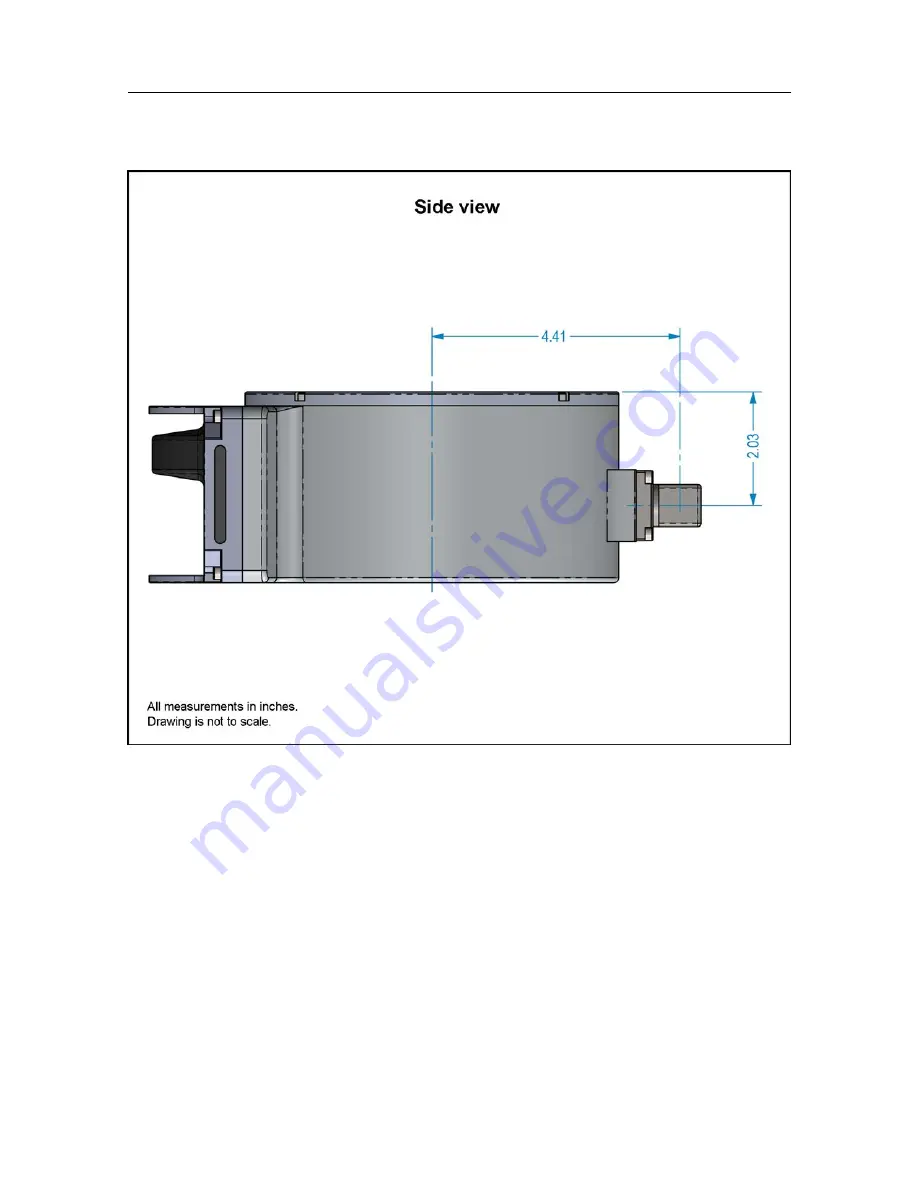

Page 95: ...922 20207011 1 0 93 Flexview Sonar Head 500 kHz outline dimensions Drawing file ...

Page 96: ...94 922 20207011 1 0 Flexview Installation Manual ...

Page 97: ...922 20207011 1 0 95 Drawing file ...

Page 99: ...922 20207011 1 0 97 Drawing file ...

Page 100: ...98 922 20207011 1 0 Flexview Installation Manual ...

Page 126: ... 2019 Kongsberg Mesotech ...