37

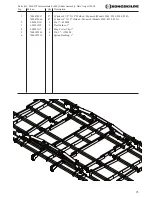

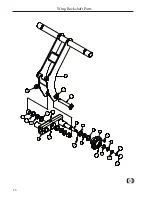

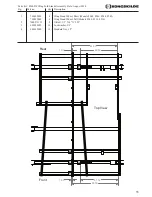

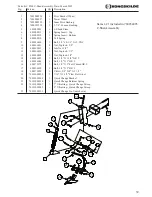

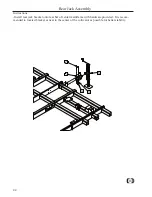

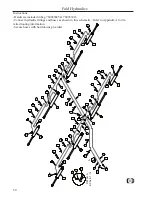

Parts list / 8200 DF Tine Assembly. Date: March 2014

Fig.

Part no.

Qty Description

1a

101003154

1 16.3mm Coil

1b

101003159

1 13.3mm Coil

2

101000837

1 Stem, 50mm x 10mm

3a

760031123

1 16.3mm Coil Clamp

3b

760031122

1 13.3mm Coil Clamp

4

6100323128

2 M12 x 48mm Share Bolt with Hex Nut

5

600355030

1 Bolt, 5/8" x 5-1/2" - UNC Gr.8

6

600366031

1 Nut, Toplock 5/8"- UNC

7

600373076

1 Bolt, 5/8" x 1-3/4" - UNF Gr.8

8

600366025

1 Nut, Toplock 5/8" - UNF

9

101002004

1 4" 8mm Heavy Duty Sweep

10

101002003

-

4" 6mm Sweep

11

101002002

-

2-3/4" 6mm Heavy Duty Goosefoot Share

12

101002005

-

7" 6mm Sweep

13

101002006

-

7" 8mm Heavy Duty Sweep

14a

760033023

-

VTH - 16.3mm Tine and Coil Assembly (Includes Items 1a,2,7,8)

14b

760033022

-

VTH - 13.3mm Tine and Coil Assembly (Includes Items 1b,2,7,8)

760034001

-

VTH - 16.3mm Heavy Duty Tine Package (Includes Items 3a,4,5,6,14a)

760034000

-

VTH - 13.3mm Standard Duty Tine Package (Includes Items 3b,4,5,6,14b)

�����

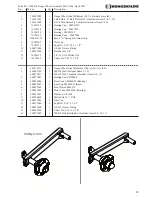

Summary of Contents for 8200 DF Series

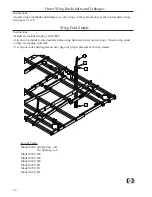

Page 8: ...8 Center Rockshaft Parts...

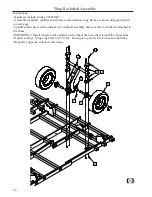

Page 26: ...26 Wing Rockshaft Parts...

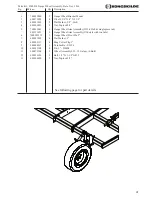

Page 42: ...42 Gauge Wheel Assembly Parts 1 2 11 6 7 9 8 10 12 5 3 4 13 14 14 Old Style Arm...

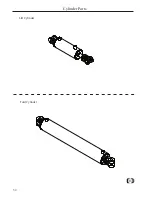

Page 52: ...52 Cylinder Parts Lift Cylinder Fold Cylinder...

Page 62: ...62 Decal Placement Instructions Attach decals to clean surface as shown below...

Page 68: ...68 Appendix B Torque Chart...

Page 70: ...760000229 May 2015...