16

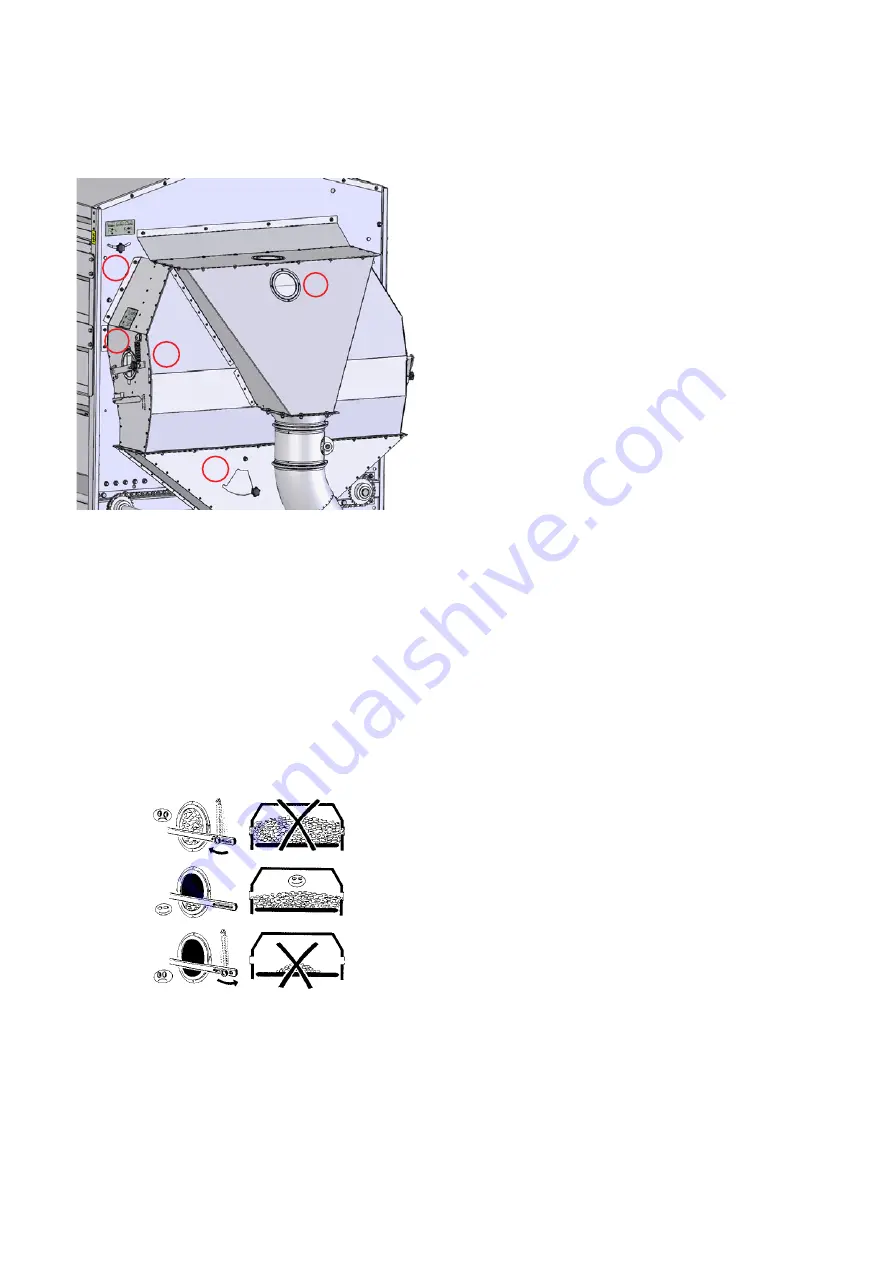

3. Adjust the spring-loaded device (C) of the "grain

shutter", so that the shutter will not open until there

is grain throughout the width of the shutter. This may

be checked through the inspection window (2) on

the sides.

Loosen the thumbscrew, push to the desired posi-

tion and tighten. As a starting point, the handle

should be placed in the middle for wheat and barley.

For lighter crops, move the thumbscrew to the left,

and for heavier crops, move the screw to the right.

When the cleaner is running, the crop is checked

according to the illustration.

The spring load device determines how long the

grain remains in the aspiration chamber.

4. Adjust the air slot in the aspiration cleaner using the

handle (D), to avoid extraction of too many whole

grains. Loosen the thumbscrew, push to the desired

position and tighten.

This may be checked as follows

4.1 If there are many whole kernels in the

screenings, they will produce noise in blower and

pipeline.

4.2 Collect the screenings after the dust

cyclone and check that there are not too

many whole kernels.

4.3 The screenings can also be inspected

through the window on the back of the

aspiration cleaner.

5. When handling light crops, too many whole kernels

may be extracted, although the aspiration

cleaner is set to minimum extraction. In such cases,

open the damper (A) a little.

Control of cleaning / sorting efficiency

After the initial adjustment of the cleaner, and operation

at the capacity stated for two or three minutes, samples

should be taken to check if the desired final result has

been achieved.

Sampling can be done at the opening (E).

Loosen the thumbscrew, push the damper to the left

and extract the sample through the opening. Beware of

sharp edges, and remember to close the shutter after

finishing sampling.

If the cleaner is used for sorting, it is required that there

is a certain size difference between the two crops that

are to be sorted.

If the sorting between the two crops is too low, reduce

the capacity, and if it is too high, increase the capacity.

As crops will vary, however, it will be wise to allow for a

minor safety margin.

If the capacity is changed, new samples will have to be

taken. Continue this way until the desired grading result

of the finished product has been obtained. When the

correct capacity setting has been reached, it is recom-

mended to deliver a sample of the finished product to

the feedstuff dealer for testing, as the test screens are

intended as a guide only.

B

C

E

1

2