7

Location

The cleaner can advantageously be installed, so that

the crop is cleaned both when it is being put on stock,

and when it is taken out of stock again.

The capacity is generally dependent on the requirement

for purity, as less load of the screens, provides better

opportunities for the removal of impurities.

The transport system must therefore be designed so

that it is possible to regulate the supply of material to

the cleaner.

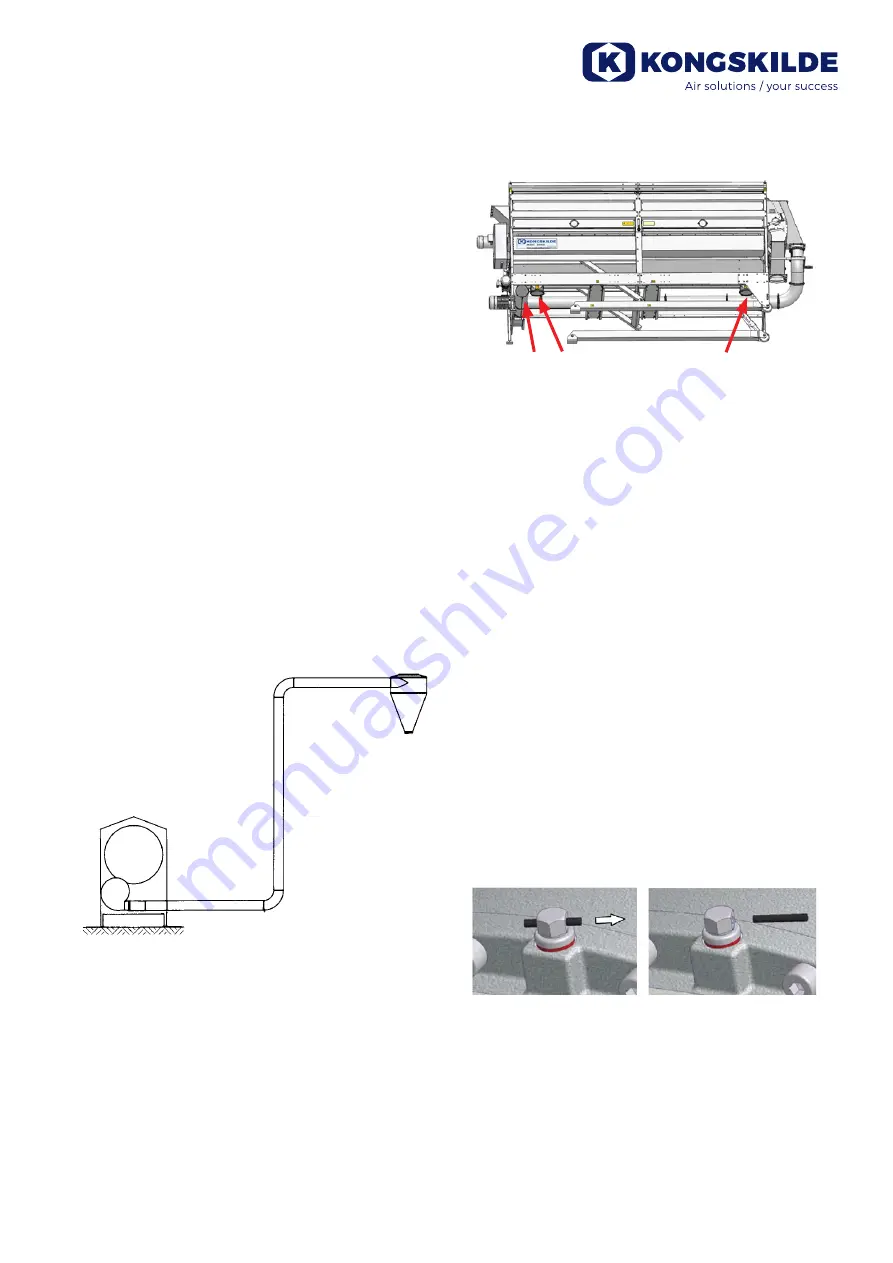

Make sure there is clearance next to the cleaner, to

make the necessary adjustments and service.

Also, remember that there must be room for replacing

the screens. It is easiest to replace the screens at the

right side of the cleaner (seen from the inlet end). The

screens are easily replaced if there are approx. 1,5 m

clearance beside the cleaner.

Pipeline for blower

The blower pipeline should be of the Kongskilde OK200

dimension. It is recommended to use as few bends as

possible and a cyclone at the end of the pipeline.

At a commonly occurring content of impurities in the

crop, the blower is powerful enough to blow the screen-

ings approx. 20 m (including 4 meters vertical length,

two bends and one cyclone).

If to much blower power is applied to conveying, this

will reduce the air flow and, accordingly, the

cleaning efficiency of the aspiration cleaner. If addition

-

al conveying length is required, an extra blower may be

inserted.

Separation of screenings

The screenings may either be discharged through a

separate gravity outlet or delivered into the trash blow

line (A) and discharged together with the light impuri-

ties.

Impurities separated by screens and aspirator dis-

charged into the trash blow line

Mount the enclosed covering plate in the outlet (B) and

(C) of the trough auger.

Impurities separated by screens and aspirator dis-

charged separately

Remove the covering plate from the outlet (B) of the

trough auger. If desired, a shutter may be fitted instead

of the covering plate.

Oversized impurities separated by inner screens can

also be discharged separately.

Oversized impurities separated by inner screens

discharged separately

Remove the covering plate from the outlet (C) of the

trough auger. If desired a shutter may be fitted instead

of the covering plate.

Be aware of the danger of touching the rotating auger,

see section "Warning notes" and the warning sign on

the bottom trough.

Drum gear motor

In order to avoid oil spills during transport, the gear vent

is closed with a blunt rubber cord. This sealing cord

must be removed before using the cleaner.

B

C

A

90°

90°

4 m

Cyclone

OK200 pipe system