10

Mode of operation:

Screen selection

To obtain optimal efficiency, it is important to use

screens of correct slot/hole dimensions (see section

"Screen sizes").

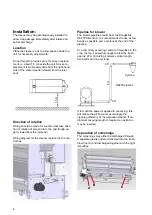

Screen replacement

Always stop the cleaner before removing the

guards for the screen drum, and avoid unintentional

start of the cleaner during replacing the screens.

Lock e.g. the on/off switch on the built in control box

or a safety switch mounted in the electrical installa-

tions to avoid unintentional start of the cleaner dur-

ing replacing the screens.

Never turn the screen drum by switching on the

gear motor, when replacing the screens - the drum

can easily be turned by hand.

Always use gloves when replacing screens. The

screens may have sharp edges.

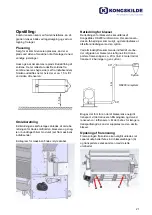

Both the inner and outer screens have a quick-re-

lease system attached to the screens to allow easy

replacement. Always mount the screens on the

screen drum with the handle of the quick-release

clamps turning in the direction shown, in order to

avoid unintentional release.

The clamps are released by pushing their sides

together. The clamp tension can be adjusted by

turning the T thread rod.

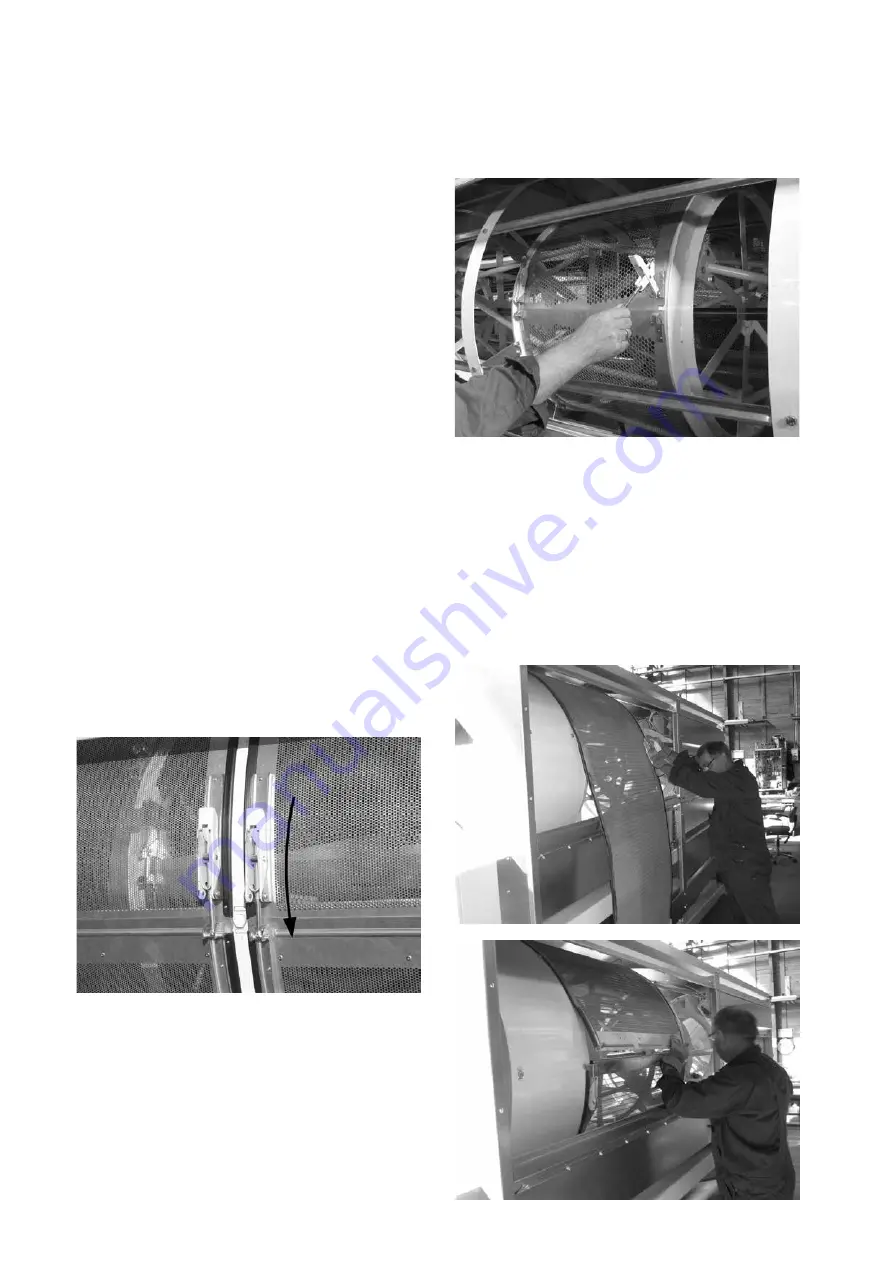

Remove the screws for the covers, and set aside

the covers. Thereafter remove the middle sprosse.

Installation of inner screen

The inner screen is installed by guiding it around

the screen drum, and turning the drum to enable

the screen ends to be clipsed together. The cleaner

contains 3 inner screens.

Installation of outer screen

Outer screen replacement is most easily done from

the right-hand side of the cleaner (viewed from the

inlet end).

The outer screen is installed by placing the screen

end opposite of the quick release clamps under

the cleaner. Thereafter the u profile is hooked onto

the cross bar on the drum, in the screen end with

the quick release clamps. The drum is now turned,

enabling the screen clamps to be clipsed together

as shown. The cleaner contains 2 outer screens.