12

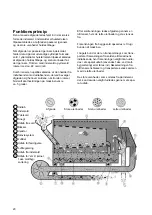

3. Adjust the spring-loaded device (C) of the "grain

shutter" so that the shutter will not open until

there is grain throughout the width of the shutter.

4. Adjust the air slot in the aspiration cleaner using

the handle (D), to avoid extraction of too many

whole grains.

This may be checked as follows

4.1 If there are many whole grains in the

screenings they will produce noise in fan

and pipeline.

4.2 Collect the screenings after the dust

cyclone and check that there are not too

many whole grains.

4.3 The screenings can also be inspected

through the window on the back of the

aspiration cleaner.

5. In handling light crops too many whole grains

may be extracted, although the aspiration

cleaner is set to minimum extraction. In such

cases, open the air slide (A) a little.

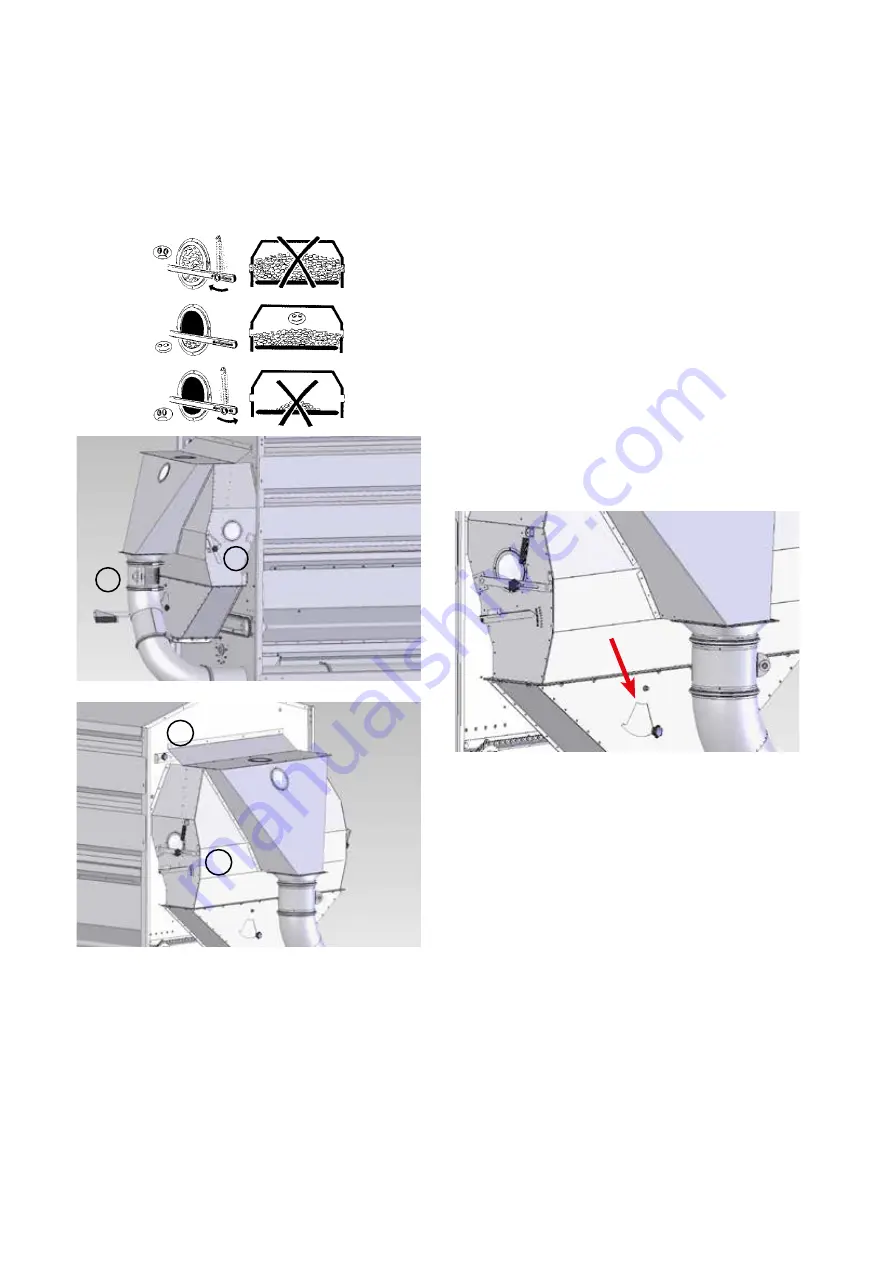

Control of cleaning efficiency

After the initial adjustment of the KDC 4000 and

operation at the capacity stated for two or three

minutes, samples should be taken to check if the

desired final result has been achieved.

The finger knob is loosened, the throttle is pushed

to the right, and a test sample can be taken through

the opening. Watch out for sharp edges, and re-

member to close the throttle after use.

Malting barley grading

In the grading of malting barley, the small-sized

grains are separated on the outer screen.

Considerably larger quantities are to pass through

the outer screen when grading malting barley than

in ordinary pre-cleaning of grain. In the grading of

malting barley it is therefore normally the capacity

of the outer screen that determines the capacity of

the cleaner.

In the grading of malting barley the impurities from

screens and aspiration cleaner are usually kept

apart, as it is not desirable that the small grains mix

with the impurities from the aspiration cleaner.

Therefore remove the covering plate from the outlet

(B) of the trough auger.

Use, for instance, a Kongskilde TRL blower with a

venturi to discharge the small grains.

B

C

D

A