15

Service and maintenance:

Bearings

All bearings are lubricated for life from the factory,

and requires no maintenance.

Gear for screen drum

The gear is supplied from

the factory with synthetic

oil, ISO VG 680. Check

the oil level in the gear on

a regular basis. Change

oil every 20.000 running

hours, or latest after 4

years (at synthetic oil). At

mineral oil, the intervals will be halved.

Oil type

See separate manual for the gear drive.

Never mix synthetic oil and mineral oil. If you want

to change oil type, it is necessary to clean the gear

very carefully.

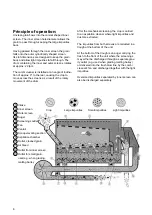

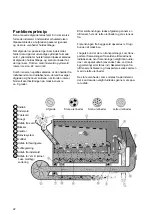

Greasing of intermediate bearing on trough

auger

The intermediate bearing on the trough auger is

positioned in the bottom trough in the middle of the

cleaner.

The bearing construction is a steel shaft running in

a nylon bushing with facility for greasing.

Greasing of the bearing is extending lifetime of the

nylon bushing. It is beneficial to grease the bearing

each 40 hours of running. Preferable grease type

is: Mobiltemp SHC 460 Special, or similar grease

with content of graphite or/and MoS

2

.

Belt tensioning

Check at regular intervals that the belt is taut, espe-

cially while it is new. The first belt tensioning should

normally take place after 2 - 3 hours of operation.

Re tightening

In a new machine, all screws and bolts should be re

tightened after the first day of operation. Make sure

that they are always securely tightened.

Cleaning

Clean the machine if it is to stand idle for a consid-

erable period of time. Keep gear and motors free

from dirt, which may reduce the cooling.

Storage

If the cleaner is used for outdoor installation, and

will be out of use for a longer period, it is recom-

mended to open the outlets from the auger to avoid

water being collected in the bottom of the machine.

Technical data:

Max. capacity, pre-cleaning of grain

app. 80 t/h

Screen area

• Inner screen ............................................7,75 m

2

• Outer screen ..............................................

9,9 m

2

Motor output / motor rpm (50 Hz)

• Screen drum .................

2,2 kW (3 HP)/1500 rpm

• Fan ...............................

4 kW (5,5 HP)/3000 rpm

• Auger .........................

1,1 kW (1,5 HP)/1500 rpm

Motor output / motor rpm (60 Hz)

• Screen drum ................................

3 HP/1750 rpm

• Fan ..............................................

5 HP/3500 rpm

• Auger ........................................

1,5 HP/1750 rpm

Screen drum .................................................22 rpm.

Weight

• Without screens ...................................... 1425 kg

• With screen ............................................ 1480 kg

Connections

• Inlet, uncleaned crop .................................FK250

• Outlet, cleaned crop ..................................FK250

• Discharge opening, fan ............................OK200

• Outlet, auger .............................................OK200

Intermediate bearing

Summary of Contents for KDC 8000

Page 1: ...KDC 8000 Combi cleaner Manual Brugsanvisning...

Page 35: ...35...