31

The blades should be ground in a special grinder to achieve the correct cutting edge and

accurate centring of the rotor shaft.

Correct grinding and adjustment of the Multicutter or granulator is necessary in order to

achieve a satisfactory result and a long working life (Please study the grinding instructions

below).

Cutting and grinding Theory

Reconditioning your cutter as specified in these instructions will restore its orginal precise

cutting capability.

The cutter works on a rotary cutting principle. Material is cut at the interface between a

fixed bed knife and rotor-mounted knives to provide two or six cuts for each complete rota

-

tion of the rotor.

Knife Clearance

True cutting requires the clearance between the rotor and bed knives be less than the

thickness of the material being cut.

The resharpening and knife setting methods result in knife clearances down to 0.0064 mm/

0.00025 in (0.0127 mm/0.0005 in for MC 5000) with no knife contact. Cutters set to this

clearance will cut all types of thin films.

Very close clearances also provide longer useful knife life. The closer the starting clea-

rance, the longer will be the operating time before the knives wear to the point they will no

longer cut.

The rotor knives of the model MC cutters or granulators are at a shear angle. This reduces

both the cutting force and the operating noise level.

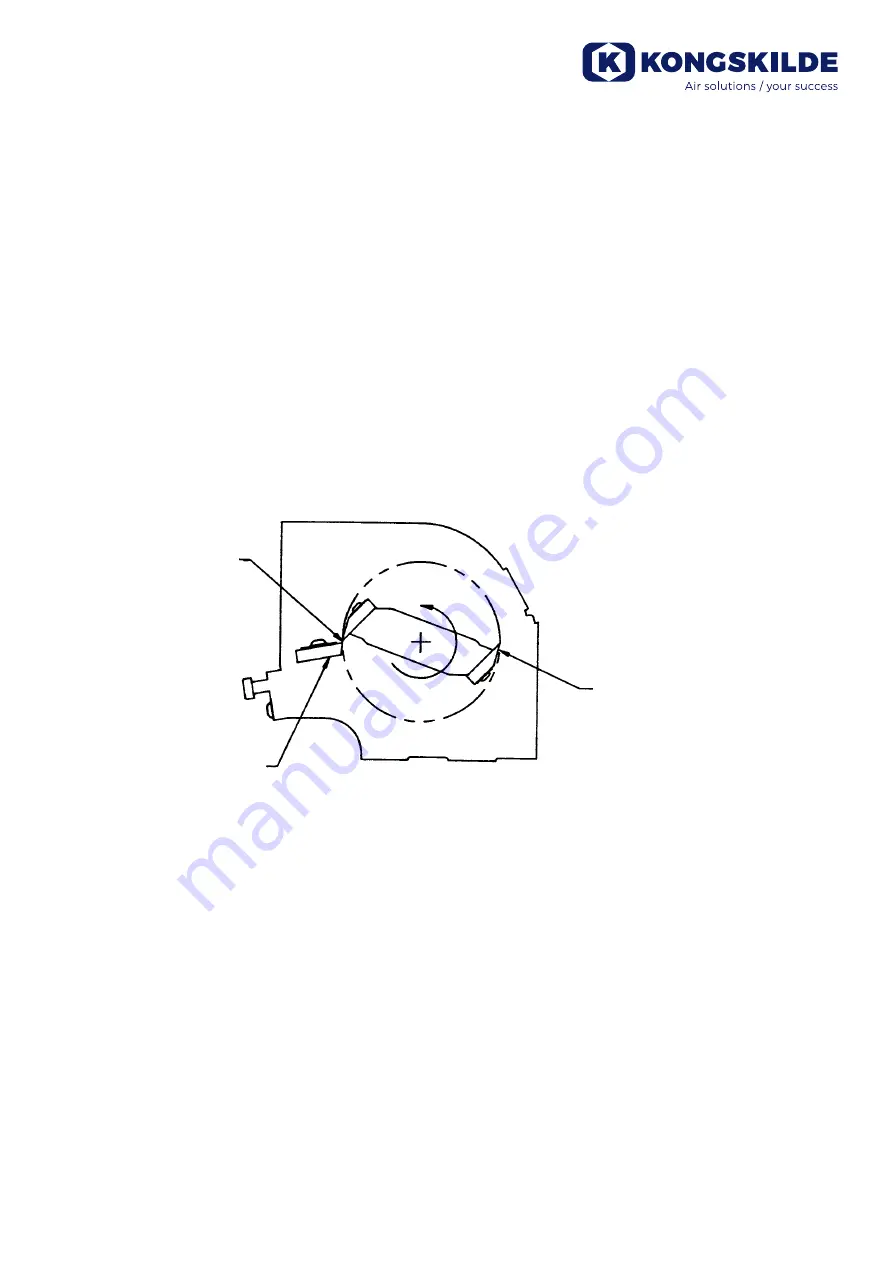

Interface

Fixed bedknife

Rotor knives

FIG.1

Summary of Contents for KG 3000

Page 15: ...15 FIG 10 ...

Page 29: ...29 FIG 10 ...

Page 43: ...43 FIG 10 ...

Page 57: ...57 FIG 10 ...

Page 71: ...71 FIG 10 ...

Page 85: ...85 FIG 10 ...

Page 99: ...99 FIG 10 ...

Page 113: ...113 FIG 10 Sección de entrada Dirección de giro de cuchillas ...

Page 127: ...127 ...

Page 129: ...129 ...

Page 130: ...130 ...

Page 131: ...131 ...