34

A: Bed knife

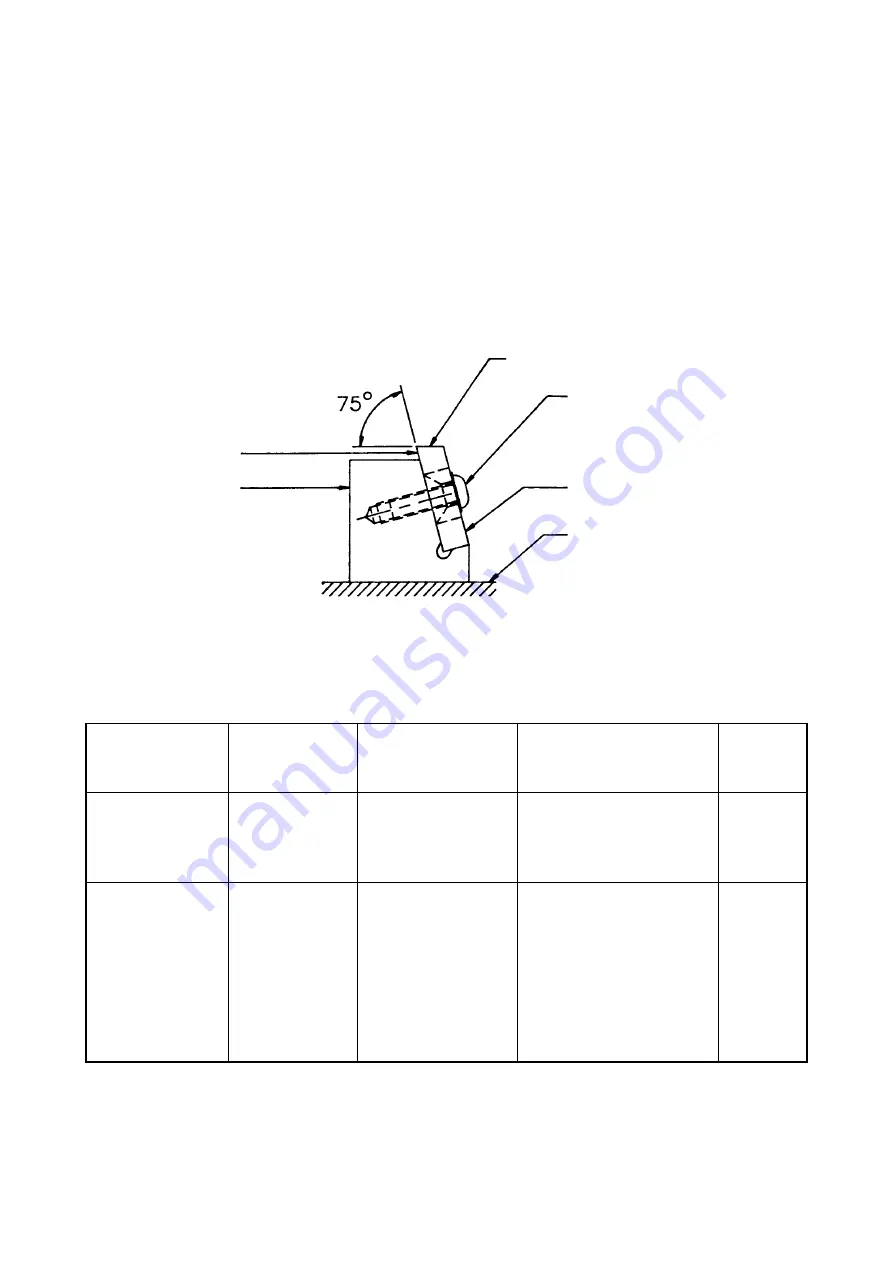

Remove nicks in cutting edge by uniformly grinding surfaces A and/or B (FIG. 3.), remo-

ving as little material as necessary. Surface A may be ground by fixing the knife flat to the

grinding table (surfaces A and C must remain parallel on the finished knife). Grind surface

B by fixing bed knife in an angled vise or the fixture (part # 121 116 251). Grind knife flat,

straight and parallel within 0.013 mm (0.0005 in).

Surface A

Bed knife grinding

fixture (part # 121 116 251)

Surface B

Button head cap screws with

disc springs (items 10 and15)

Surface C

Grinder table

FIG.3

Surface grinding parameters

Type of knife

CPM-10V

Tungsten

carbide

Type of

grinding wheel

32A60H8

D100/120

N100B or

D220N100B

Surface speed of

wheel m/sec.

(SFPM)

20.3-30.5

(4000-6000)

25.4-30.5

(5000-6000)

25.4-30.5

(5000-6000)

Grinding wheel

advance/pass

Rough: 0.025-0.075 mm

(0.001”-0.003”)

Finish: 0.013 mm

(0.0005”)

Rough: 0.0075 mm

(0.0003”)

Finish: 0.0025 mm

(0.0001”)

Rough: 0.0075 mm

(0.0003”)

Finish: 0.0025 mm

(0.0001”)

Coolant

Yes

Yes

Yes

Summary of Contents for KG 3000

Page 15: ...15 FIG 10 ...

Page 29: ...29 FIG 10 ...

Page 43: ...43 FIG 10 ...

Page 57: ...57 FIG 10 ...

Page 71: ...71 FIG 10 ...

Page 85: ...85 FIG 10 ...

Page 99: ...99 FIG 10 ...

Page 113: ...113 FIG 10 Sección de entrada Dirección de giro de cuchillas ...

Page 127: ...127 ...

Page 129: ...129 ...

Page 130: ...130 ...

Page 131: ...131 ...