36

driven from it´s drive end using the grinder drive or an external motor. Spin grind per the

parameters below. To ensure precise clearances, do not remove knives from rotor after “in-

cutter” spin grinding.

Spare rotor set-up (“Pre-ground” method)

Locate spare rotor between centres of cylindrical grinder and square knives with grinding

wheel. Drive the rotor with the grinder/granulator drive and spin grind per the below para-

meters.

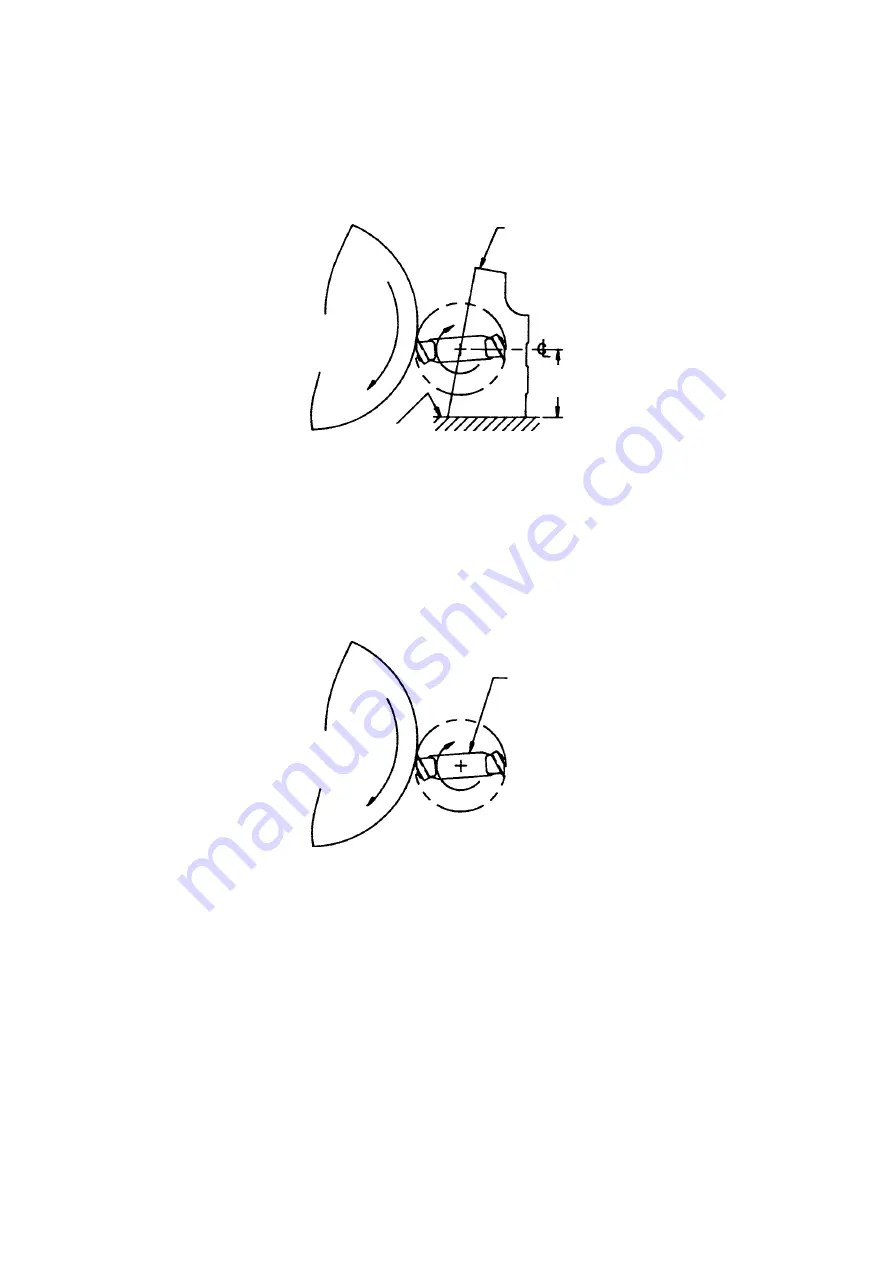

Cylindrical grinding parameters

Grind knife tips until the newly ground surfaces (or “lands”) are approximately 0.8 mm

(1/32’’) wide at the centre of the knife’s 174.6 mm (6-7/8”) length. Due to the 3-degree

shear angle, the lands on the knife ends will be larger than in the centre.

FIG. 5

FIG. 6

Cutter set on

outlet flange

Cylindrical grinder wheel

Grinder table

129 mm (5.08’’)

Cylindrical grinder wheel

Spare rotor be-

tween centres

Summary of Contents for KG 3000

Page 15: ...15 FIG 10 ...

Page 29: ...29 FIG 10 ...

Page 43: ...43 FIG 10 ...

Page 57: ...57 FIG 10 ...

Page 71: ...71 FIG 10 ...

Page 85: ...85 FIG 10 ...

Page 99: ...99 FIG 10 ...

Page 113: ...113 FIG 10 Sección de entrada Dirección de giro de cuchillas ...

Page 127: ...127 ...

Page 129: ...129 ...

Page 130: ...130 ...

Page 131: ...131 ...