11

Installation

Always check the direction of rotation of the motor

prior to mounting. Rotation of the Multicutter rotor

is anti-clockwise viewed from the motor side.

If the Multicutter rotor rotates in the opposite

direction, the knives cutting edge will be damage

immediately. Do not rotate the rotor manually in

the opposite direction as even a few rotations in

wrong direction may damage the knives.

Application

The Multicutter is designed for cutting down trims of

plastic foils, aluminum foils, paper and cardboard.

The maximum thickness of plastic foils is 400 my, while

the maximum thickness of aluminum foils is 50 my.

The maximum weight for trims of paper and cardboard

is 500 g/m

2

.

The Multicutter is designed for mounting in an

enclosed pipe system, that is, with a pipeline mounted

both at the inlet and outlet of the Multicutter.

Only use the Multicutter for cutting the materials it

is designed for due to risk of knives destruction or

damage.

Always check the direction of rotation of the motor

prior to mounting. Rotation of the Multicutter rotor

is anti-clockwise viewed from the motor side.

If the Multicutter rotor rotates in the opposite

direction, the knives cutting edge will be damage

immediately. Do not rotate the rotor manually in

the opposite direction as even a few rotations in

wrong direction may damage the knives.

The Kongskilde Multicutter may only be operated

and serviced by responsible and properly instructed

people.

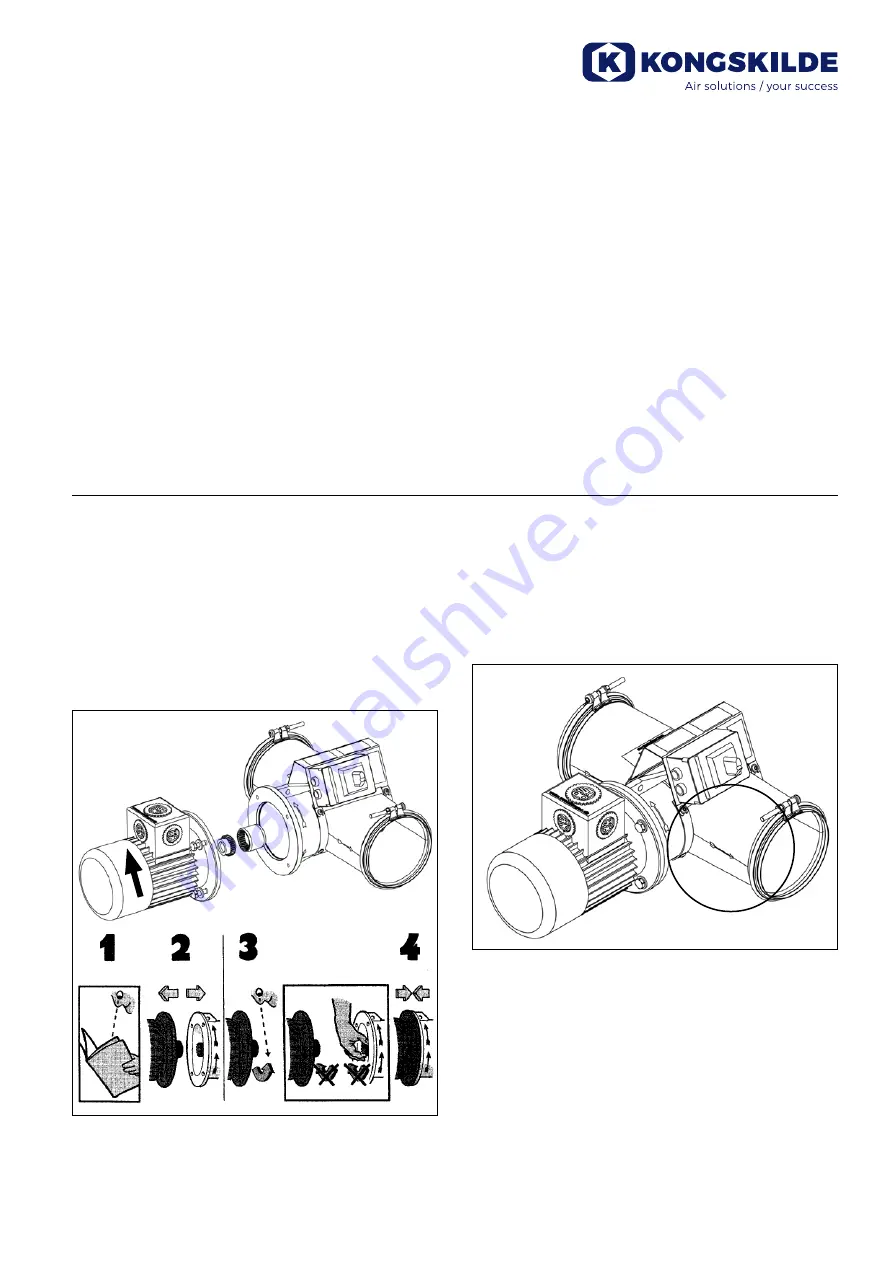

Mounting the motor

The Multicutter is designed for mounting in an

enclosed pipe system, that is, with a pipeline mounted

both at the inlet and outlet of the Multicutter.

Make sure the material is passing through the

Multicutter in the direction indicated by the arrow at the

inlet.

If the Multicutter is suspended in a pipe system it

must be secured with a wire or similar attaching

the Multicutter to the building in order to prevent

the Multicutter from loosening and falling down by

accident.

Flow direction