12

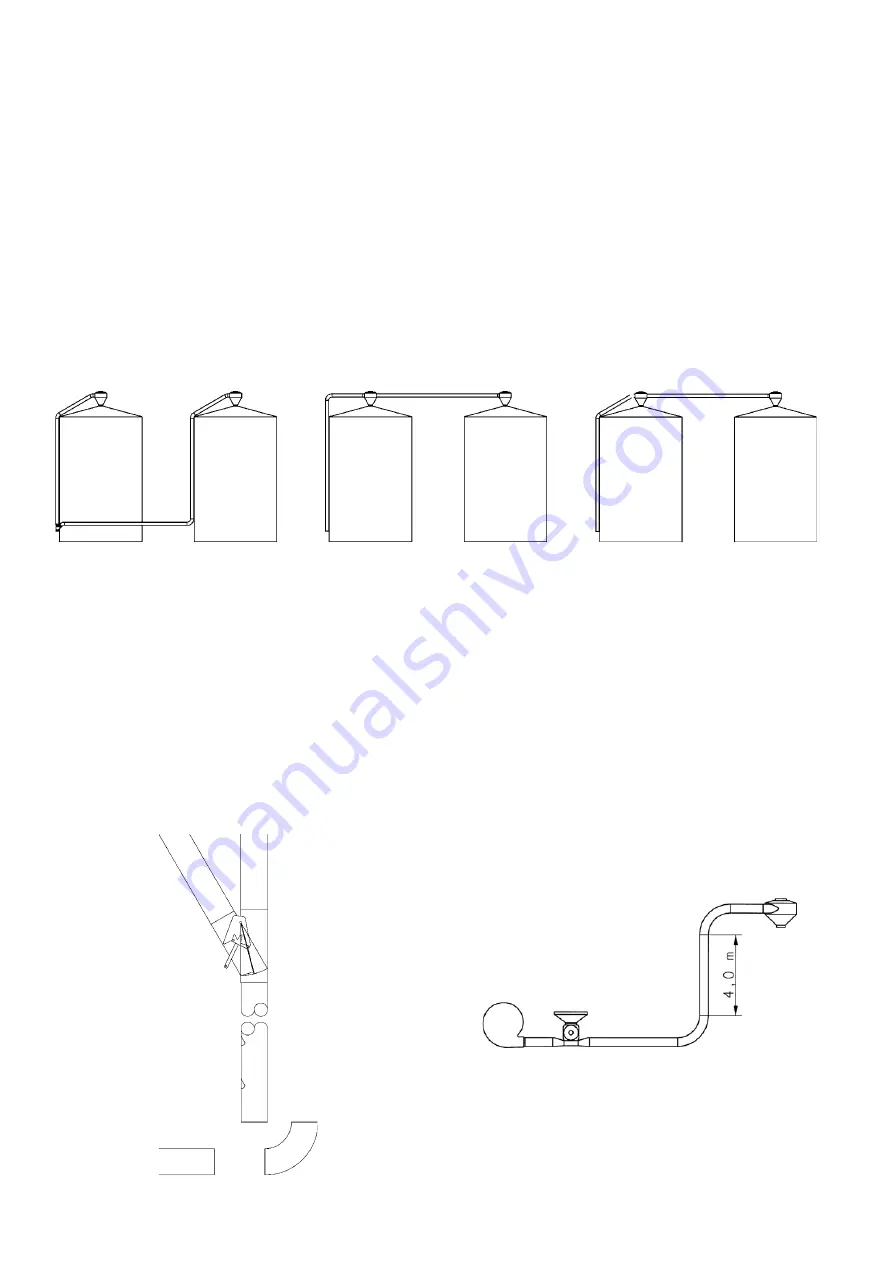

Pipe layout:

Direction of pipeline

Keep the pipeline horizontal or vertical. Longer sloped

rising or falling distances will result in wear on the

pipes, risk of plugging of pipes, damage to the material

and capacity loss. The only time sloping pipe layout

is advisable is right before the material reaches its

destination.

Conveying to two or several difficult accessible

destinations

When conveying grain through areas, where service

is difficult, e.g. high silos, it can be considerably less

expensive long term to use several separate pipelines,

as in example 1. Investment is slightly more expensive

than example 2, but it is normally easier and less

expensive to make service on this plant, and wear on

the pipes is reduced considerably, becausen not all

grain for both silos should pass through the same pipe.

Right

Wrong

Eks. 1

Eks. 2

Right

Condensed water in outdoor piping systems

With outdoor piping systems condensed water

will arise in the pipes especially in the winter time.

Therefore it is recommended to disconnect a pipe or

a bend at the lowest points, when the system is not

to be used for a longer time in order to avoid water

accumulation and rust.

If diverters are installed outdoor, these should stay

in the middle position so that water can not be

accumulated here thus reducing rust and corrosion.

If possible blower, rotary valve and diverters shall

always be placed indoor/ under roof.

Conveying capacity (grain):

Conveying capacity in tons per hour for normal clean,

dry barley.

The capacities stated apply to a standard pipeline.

The standard pipeline consist of a number of metres

horizontal piping, 4 m (13 ft) vertical piping, two 90°

bends and an outlet cyclone.

Note: Equipment performance may vary with type

of material and operating conditions. Please consult

with the manufacturer for more detailed performance

specifications.

Standard pipeline

(13 ft)