5

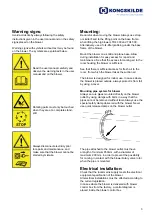

Start

Conveying

Interrupted

Star position

Delta position

Rotary valve

Start the rotary valve when the blower has reached

full speed. (The blower can also be delivered with

automatic start of the rotary valve).

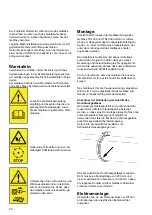

The conveying capacity is regulated by means of the

intake shutter on the rotary valve. For blowers with

air intake regulator the biggest capacity is reached by

slowly opening the intake shutter of the rotary valve

until the indicator on the blower intake regulator is

about 10mm (3/8 in.) from the left stop. For blowers

without air intake regulator, maximum capacity can

only be achieved by trial and error.

Venturi

The venturi is self-regulating. It does not take in more

material than the blower can cope with. Where the

venturi is provided with an intake shutter, this must be

opened fully when the blower is started.

Stop:

If possible, run the pipe system clean before stopping

the blower. The rotary valve must therefore either be

stopped before the blower or at the same time. Never

stop the blower before the rotary valve, as this can

cause the pipe system to block.

Even in cases where the piping system is not clean

when the blower is stopped, this normally will not

cause problems. It is therefore also possible to

keep the rotary valve/venturi in the same position

while starting and stopping the blower.

Service and maintenance:

Always stop the blower prior to repair and maintenance

and avoid unintentional start of the blower.

Retightening

On a new blower, all bolts and screws are to be

retightened after the first working day. Apart from that,

make sure that they are tight at all times.

Cleaning

Regularly check the surfaces of the blower and motor

for dust and other impurities. If the dust layer is more

than 0,5 mm (0,02") thick, it must be removed. It will

depend on the dust content in the blower surroundings,

how often it is necessary to check/clean the blower

and motor.

Greasing

Except from TRL 500, all bearings on all TRL blowers

have been greased from the factory and do not need

any further greasing.

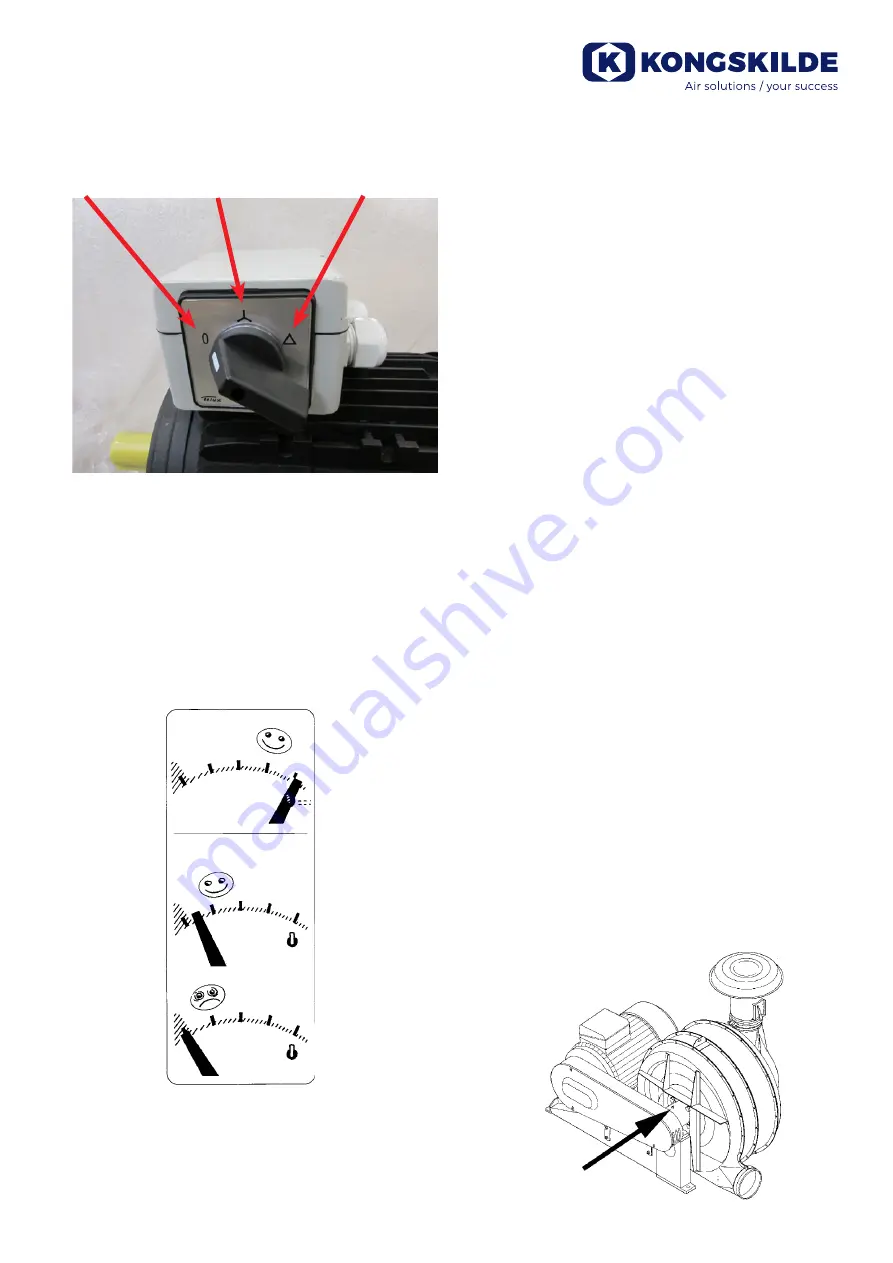

TRL 500 only:

Grease the bearings on the blower belt

side every 200 working hours. Use a lithium based

grease of minimum quality as Mobil Mobilux EP2 or

Esso Beacon EP2. Regrease with approx. 20 cm

3

= 20

gram (1.2 cub.in.) each time. Never over grease the

bearings. If the casing is filled with too much grease,

the bearings will get hot.

TRL 500