8

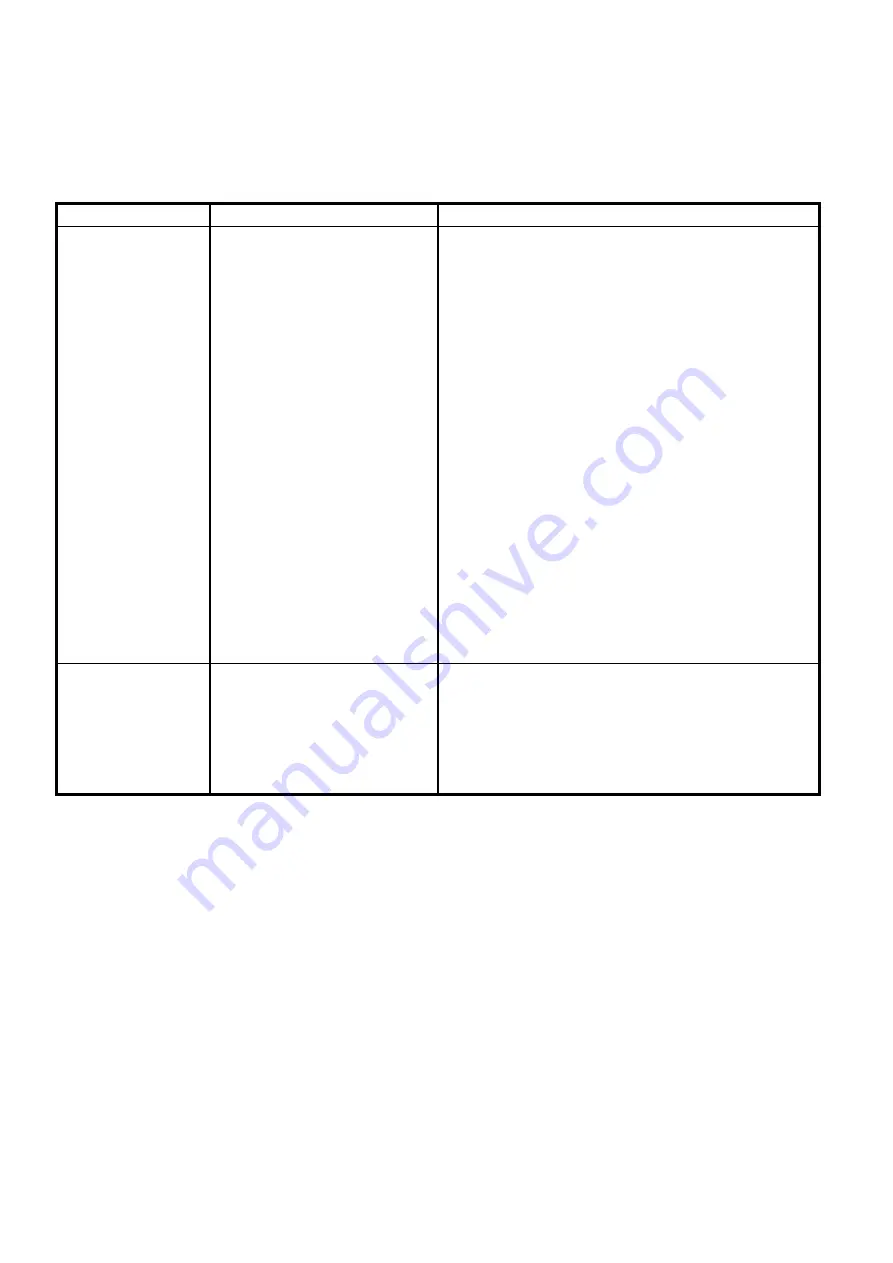

Troubleshooting:

Fault

Cause

Remedy

Poor capacity

Feed not correctly adjusted.

Piping incorrectly installed.

Rotation direction of blower (or

rotary valve) incorrect.

Material being blown into contai-

ner with inadequate air outlet.

Worn seals in rotary valve.

V-belts are too slack or possibly

worn out.

Intake regulator shutter cannot

move freely.

The rotary valve / venturi does

not match the blower.

Rotary valve / venturi is pointing

in wrong direction

See section ”Start”.

See section ”Pneumatic conveying”.

Change direction of rotation. Correct direction is shown

in section “Electrical installation”.

Open container to allow air to escape.

Replace seals.

Tighten or replace the V-belts. See section “Service

and maintenance”.

The shutter is not released from start position, or the

function of the shutter is impeded by impurities, and ne-

eds to be cleaned.

Use the correct feed. See section “Conveying capa-

city”.

Reverse the feed – see arrow on rotary valve / venturi

Conveying stopped

but blower continues

to operate

Pipe blockage.

Rotary valve rotor blocked by

impurities in the material

Close the intake shutter at the rotary valve, and see

whether the blower itself is able to clear the piping. If

this is not possible, the piping must be dismantled and

emptied.

Remove impurities, and check whether rotor has been

damaged