40

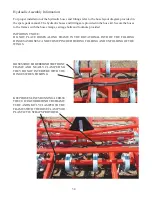

5) Install Red Safety Reflectors #600475132 on bothrear fold brackets and sides of the 2900 centre

section.

RED REFLECTORS on Rear

Hinges and side bar

If the rear reflector position could be blocked from view by harrow mounting brackets then the reflector

can be place in an alternate position on the rear corner of the toolbar to provide better visibility.

RED REFLECTORS on

Rear Toolbar Tube and Side Bar

Summary of Contents for VIBRO TILL 2900 Series

Page 44: ...44 660 005 033 February 2016...