1 - 133

OTHER ADJUSTMENT

[20] FNS Adjusting the Paper Exit-

Opening Lower Guide Plate

1. Tools used

• Screwdriver (Phillips)

• Scale

2. Preparation

(1) Remove the following parts.

• Rear cover

• Top cover

• PI-108 (if installed)

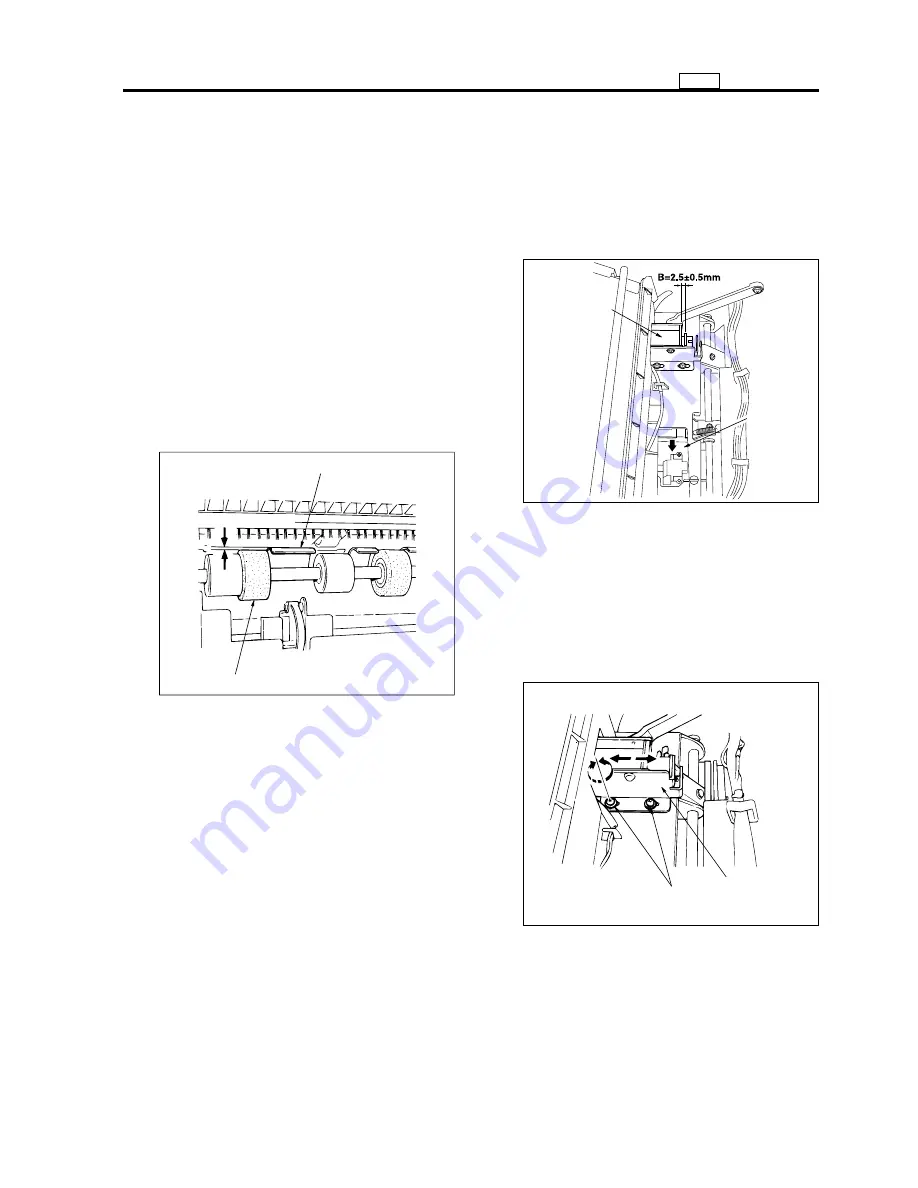

(2) With SD4 (paper exit-opening solenoid) OFF,

confirm that the paper exit-opening lower guide

plate is a sufficient distance (distance A) higher

than the sponge rollers.

Spec value: A = 1.5mm and greater

Lower Guide Plate

Sponge Roller

A=1.5mm and greater

(3) Hold down the paper exit-opening lower guide

plate with your hand so that the paper exit roller

makes contact, and check that the remaining

stroke for solenoid SD4 (distance B) is within

spec.

Spec value: B = 2.5±0.5mm

SD4 (Paper Exit

Opening)

Paper Exit

Lower

Guide Plate

(4) If either measurement is out of spec, carry out

adjustment as described below.

3. Adjustment Procedure

(1) Loosen the 2 set screws holding the solenoid

bracket in place, and adjust the position of the

bracket so that distances A and B are within spec.

Screws

Solenoid Bracket

(2) Retighten the 2 bracket set screws.

(3) Reassemble in the reverse sequence to removal.

Summary of Contents for 7075/FORCE 75

Page 1: ...FEBRUARY 2003 CSM 7075 F75 7085 F85 SERVICE MANUAL MODELS 7075 FORCE 75 7085 FORCE 85...

Page 2: ......

Page 3: ...7075 FORCE 75 7085 FORCE 85 SERVICE MANUAL FEBRUARY 2003...

Page 39: ...OUTLINE 1...

Page 40: ...Blank page...

Page 55: ...1 15 MAIN BODY 11 Paper Exit Drive Section FRONT Paper exit roller Paper exit motor M10...

Page 58: ...1 18 MAIN BODY 14 Web Drive Section FRONT Web drive motor M16 Cleaning web...

Page 59: ...UNIT EXPLANATION 2...

Page 60: ...Blank page...

Page 62: ...2 A 2 EXTERNAL SECTION Blank page...

Page 120: ...2 K 6 TRAY 3 PAPER FEED UNIT Blank page...

Page 126: ...2 L 6 BY PASS TRAY Blank page...

Page 130: ...2 M 4 VERTICAL PAPER CONVEYANCE SECTION Blank page...

Page 154: ...2 O 8 FIXING UNIT Blank page...

Page 165: ...DISASSEMBLY ASSEMBLY 3...

Page 216: ...3 H 4 TONER SUPPLY UNIT Blank page...

Page 224: ...3 I 8 CLEANING TONER RECYCLE UNIT Blank page...

Page 232: ...3 J 8 PAPER FEED UNITS OF TRAYS 1 AND 2 Blank page...

Page 240: ...3 K 8 TRAY 3 PAPER FEED UNIT Blank page...

Page 292: ...3 O 18 FIXING UNIT Blank page 3 O 16...

Page 293: ...MODELS 7075 FORCE 75 7085 FORCE 85 SERVICE SECTION FEBRUARY 2003...

Page 294: ......

Page 315: ...ADJUSTMENT 1...

Page 316: ......

Page 343: ...1 19 25 ADJUSTMENT Blank page 1 19 2...

Page 372: ...1 44 25 ADJUSTMENT 1 ADJUSTMENT Blank page...

Page 458: ...1 114 OTHER ADJUSTMENT Blank page 1 112 2...

Page 497: ...ISW 2...

Page 498: ......

Page 511: ...SERVICE 3...

Page 512: ......

Page 514: ...Blank page...

Page 550: ...3 18 SERVICE Blank page...

Page 551: ...ELECTRICAL PARTS LIST WIRING DIAGRAMS 4...

Page 552: ......

Page 611: ...JAM ERROR CODE LIST 5...

Page 612: ......

Page 625: ...5 13 JAM CODE LIST Blank page 5 11 2...

Page 659: ...TIMING CHARTS 6...

Page 660: ......

Page 678: ...6 18 TIMING CHARTS Blank page...

Page 679: ...INSTALLATION INSTRUCTIONS 7...

Page 680: ......

Page 692: ...Blank page...

Page 704: ...Blank page...

Page 724: ...Blank page...

Page 730: ...Blank page...

Page 736: ...Blank page...

Page 758: ...Blank page...

Page 780: ...Blank page...

Page 832: ...Blank page...

Page 833: ...APPENDIX 7085 OVERALL WIRING DIAGRAM...

Page 834: ......