2 - F - 2

CORONA UNIT SECTION

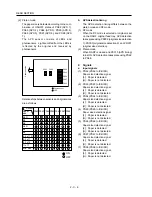

C CONT1

C CONT2

C SHIFT

SGND

G SHIFT

24VDC

PGND

C SIG

PRCB

DCPS2

HV1

CHARGING

MS2 MS1

2.

Signals

a.

Input signal

(1)C SIG (HV1 to PRCB)

Leak or short detection signal.

[L]: Normal

[H]: Abnormal

b.

Output signals

(1)C CONT1, 2 (PRCB to HV1)

Charging 1/2 output ON/OF control signal.

[L]: Charging voltage ON

[H]: Charging voltage OFF

(2)C SHIFT (PRCB to HV1)

Charging corona unit output level control signal.

The output to the charging corona unit is control-

led according to the duty ratio of the pulse (PWM)

signal sent from the PRCB.

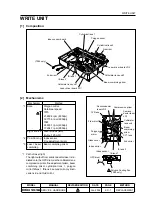

[3] Charging Control

Charging control is conducted by serial data transmitted

from PRCB (printer control board) to HV1 (high voltage

unit 1). The applied voltage for the charging wires are

supplied by HV1.

1.

Operation

a.

Charging

A Scorotron charging method is used. 24 VDC

supplied from DCPS2 is raised to a negative DC

voltage which is then discharged after being ap-

plied to the charging wire.

When the front door of this machine opens or

closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply to HV1,

stopping the voltage supply to the charging co-

rona unit and charging grid.

b.

Grid voltage

The grid voltage is output from HV1 to the charg-

ing plate.

3

C SHIFT duty

20% to 80%

Charging output range -500µA to -1900µA

(3)G SHIFT (PRCB to HV1)

Charging grid output level control signal.

The output to the charging grid is controlled ac-

cording to the duty ratio of the pulse (PWM) sig-

nal sent from the PRCB.

G SHIFT duty

20% to 80%

Grid voltage output range -400 V to -1000 V

METHOD

REPLACEMENT

MODEL

7075/7085

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3

DATE

Jan. 2002

PAGE

2-F-2

Summary of Contents for 7075/FORCE 75

Page 1: ...FEBRUARY 2003 CSM 7075 F75 7085 F85 SERVICE MANUAL MODELS 7075 FORCE 75 7085 FORCE 85...

Page 2: ......

Page 3: ...7075 FORCE 75 7085 FORCE 85 SERVICE MANUAL FEBRUARY 2003...

Page 39: ...OUTLINE 1...

Page 40: ...Blank page...

Page 55: ...1 15 MAIN BODY 11 Paper Exit Drive Section FRONT Paper exit roller Paper exit motor M10...

Page 58: ...1 18 MAIN BODY 14 Web Drive Section FRONT Web drive motor M16 Cleaning web...

Page 59: ...UNIT EXPLANATION 2...

Page 60: ...Blank page...

Page 62: ...2 A 2 EXTERNAL SECTION Blank page...

Page 120: ...2 K 6 TRAY 3 PAPER FEED UNIT Blank page...

Page 126: ...2 L 6 BY PASS TRAY Blank page...

Page 130: ...2 M 4 VERTICAL PAPER CONVEYANCE SECTION Blank page...

Page 154: ...2 O 8 FIXING UNIT Blank page...

Page 165: ...DISASSEMBLY ASSEMBLY 3...

Page 216: ...3 H 4 TONER SUPPLY UNIT Blank page...

Page 224: ...3 I 8 CLEANING TONER RECYCLE UNIT Blank page...

Page 232: ...3 J 8 PAPER FEED UNITS OF TRAYS 1 AND 2 Blank page...

Page 240: ...3 K 8 TRAY 3 PAPER FEED UNIT Blank page...

Page 292: ...3 O 18 FIXING UNIT Blank page 3 O 16...

Page 293: ...MODELS 7075 FORCE 75 7085 FORCE 85 SERVICE SECTION FEBRUARY 2003...

Page 294: ......

Page 315: ...ADJUSTMENT 1...

Page 316: ......

Page 343: ...1 19 25 ADJUSTMENT Blank page 1 19 2...

Page 372: ...1 44 25 ADJUSTMENT 1 ADJUSTMENT Blank page...

Page 458: ...1 114 OTHER ADJUSTMENT Blank page 1 112 2...

Page 497: ...ISW 2...

Page 498: ......

Page 511: ...SERVICE 3...

Page 512: ......

Page 514: ...Blank page...

Page 550: ...3 18 SERVICE Blank page...

Page 551: ...ELECTRICAL PARTS LIST WIRING DIAGRAMS 4...

Page 552: ......

Page 611: ...JAM ERROR CODE LIST 5...

Page 612: ......

Page 625: ...5 13 JAM CODE LIST Blank page 5 11 2...

Page 659: ...TIMING CHARTS 6...

Page 660: ......

Page 678: ...6 18 TIMING CHARTS Blank page...

Page 679: ...INSTALLATION INSTRUCTIONS 7...

Page 680: ......

Page 692: ...Blank page...

Page 704: ...Blank page...

Page 724: ...Blank page...

Page 730: ...Blank page...

Page 736: ...Blank page...

Page 758: ...Blank page...

Page 780: ...Blank page...

Page 832: ...Blank page...

Page 833: ...APPENDIX 7085 OVERALL WIRING DIAGRAM...

Page 834: ......