FS-107

3-2

1

O

UTLINE

2

UNIT EXPLANA

TION

3

D

IS./ASSEMBL

Y

(4)

Install by reversing the removal procedure.

Caution:

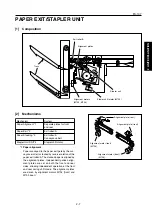

In case of fixing the tray frame to the fixed

fittings, make sure the set screws are fas-

tened so that the tray is horizontal.(Use

the 6 marks at each of the front and rear as

guides for horizontal adjustment.)

Set screws

Lids

Paper conveyance cover

Set screws

Plate spring rollers

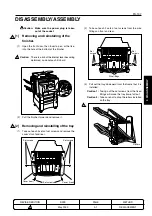

[3] Replacing the paper exit roller/A

(1)

Remove the finisher from the main body.

(2)

Take off 5 lids and 6 set screws and remove the

paper conveyance cover.

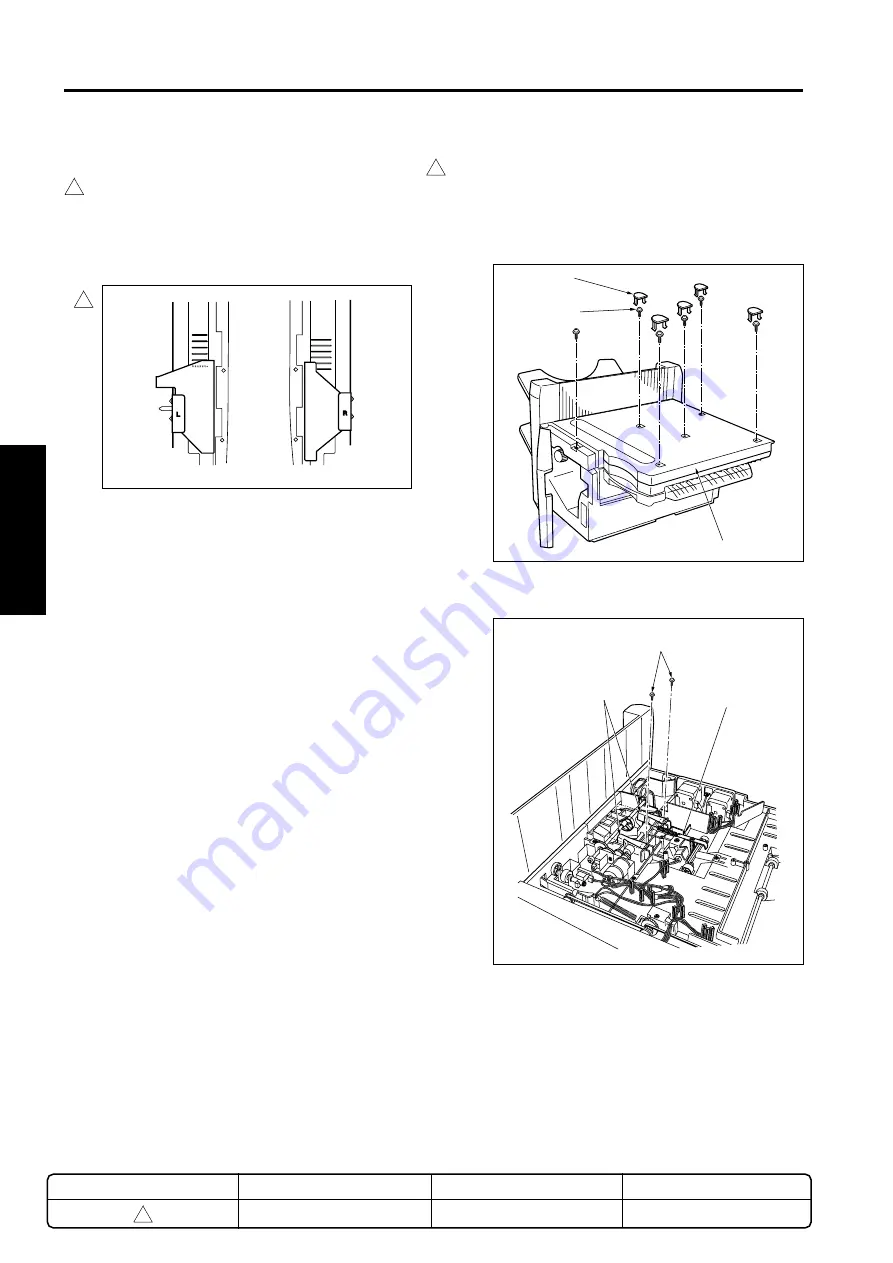

(3)

Take out each of the single springs and set screws

and remove the plate spring roller.

Caution:

Do not remove the screws for the spring

adjustment plate.

Spring

adjustment

plate

METHOD

REPLACEMENT

PAGE

3-2

DATE

May 2000

REVISED EDITION

1

1

1

1

Rear

Front

Summary of Contents for FS-107

Page 2: ...CN26NF1780 KONICA CORPORATION COPYRIGHT 2001...

Page 4: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Page 5: ...1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY OUTLINE 1...

Page 6: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Page 14: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Page 15: ...1 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY UNIT EXPLANATION 2...

Page 16: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Page 32: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Page 33: ...1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY DISASSEMBLY ASSEMBLY 3...