8

2-3 Check before installation

The voltage at working place should be reported to dealer in advance.

The power input jack of machine power is on the left side of equipment back.

The temperature of air-conditioning in room should be sufficient to following

temperature (15 - 35

℃

).

Customers should prepare appropriate tool to install the machine in advance: a

forklift over 1-ton or a crane over 1-ton. Customers must notify Printer company

all tools used, otherwise the resulting delay will be charged.

In the absence of engineers , the customer cann’t open the boxes. Any damage to

boxes should be photographed before the engineer arrives and immediately

report to the dealer.

Customers must finish all preparation and cleaning work before the engineer

arrives because dust may cause some damage to the machine.

Customers should prepare other necessary device such as Apple Computer and

Photo shop, Freehand, Illustrator etc. software that Apple Computer uses and

100M computer network.

During the installation, there’re at least two skilled computer operators next to

the machine. It’s better if they have printing experience.

Customers should be trained before starting production alone if their operators is

lack of enough experience.

The ink takes long time from order to delivery, In order not to affect the

production, customer should place orders in advance.

To minimize downtime, the manufacturer has chosen to provide some spare parts

and advise clients to buy some spare parts. If these parts have been used, please

order from Kanger immediately to make sure no shortage

Summary of Contents for KM1024

Page 1: ...1 Printer KONICA KM256 512 1024...

Page 21: ...17...

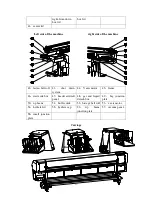

Page 22: ...18 5 2 KM256 512 1024 carriage board connection and factory writer KM512 1024...

Page 23: ...19...

Page 24: ...20 KM256...

Page 25: ...21 5 3 power outlet Main power Heater power Main power outlet Heater power outlet vacuum...