47

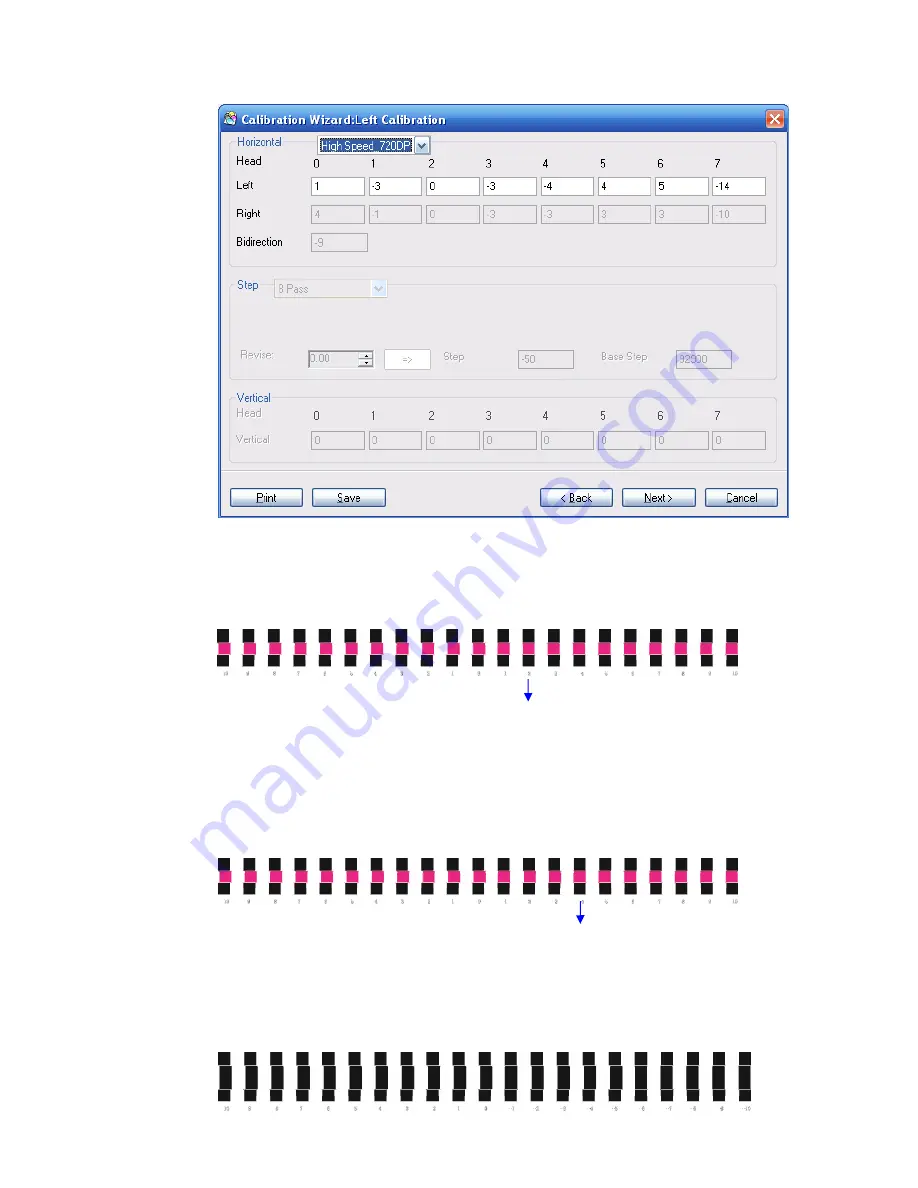

Choice speed: High speed; Medium speed or low speed

The horizontal left calibration, perform the print, check the printed pattern, take M as an

Example, see figure:

This position M and K completely to uneven

The choice pattern to the uneven position, and input correspondence numeral, the method

is adds together in the original foundation. Duplication this step, is most uneven until 0

position arrangement.

Click next, the horizontal right calibration, perform print, check the pattern, take M as

an example, see figure:

This position M and K completely to uneven

The choice pattern to the uneven position, and input correspondence numeral, the method

is adds together in the original foundation. Duplication this step, is most uneven until 0

position arrangement.

Click next, the Bidirection calibration, perform print, check the pattern, see figure:

Summary of Contents for KM1024

Page 1: ...1 Printer KONICA KM256 512 1024...

Page 21: ...17...

Page 22: ...18 5 2 KM256 512 1024 carriage board connection and factory writer KM512 1024...

Page 23: ...19...

Page 24: ...20 KM256...

Page 25: ...21 5 3 power outlet Main power Heater power Main power outlet Heater power outlet vacuum...