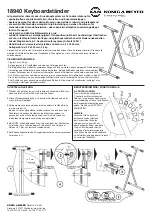

B. SETUP VARIATIONS

CHECK, MAINTENANCE, CLEANING

In the event of workstation maintenance pay attention to possible risks

(the stand is bumped into, pinching/ wedging). To care for the product

use a damp cloth and a non-abrasive cleaning agent.

FAULT FINDING (F) & REMEDY (R)

F: Stand is not stable:

F:

B: Adjust balance end caps, check surface.

F: Height/width of the stand does not fit:

F:

B: Select a different hole in the disk.

F: Keyboard is not firmly placed on the stand (unstable):

F:

B: Check the bottom of the keyboard for uneven surfaces.

F:

B: Adjust the width of the stand.

F: The keyboard is not placed on the rubber rests:

F:

B: Adjust the back rubber rings to the proper position.

C. DIMENSIONS

Transportation setting (cardboard packaging)

D. ADJUST BASES

The distances between the rubber rests can be adjusted

to the dimensions of the instrument. Just push the rubber

rests to the front until the correct distance has been

selected.

TECHNICAL DATA

Material

Tubes, struts: Steel, powder coated black

Screws, nuts, U-disks: Steel, galvanized

Locking pin: Steel, nickel plated

End caps, rubber rests/top:TPE, shore 59A

Handle, disk, caps: PA, PE

Load

max. 40 kg

Dimensions

Example: Height 620 x width 780 mm

Support tubes: ø 30 x 350 mm; Base tubes: ø 30 x 500 mm

Packaging

Box: 1020 x 520 x 102 mm

Weight

4.3 kg

Accessories

Carrying Case 18959-000-00, Stacker 18941-000-55

Keyboard “large”

Keyboard “small”

NOT OK:

Overlaps too much

NOT OK:

does not overlap

enough

NOT OK:

Not centered

OK:

Overlap

adequate

OK:

Overlap

adequate

OK:

Centered

NOT OK:

Overlaps too much

NOT OK:

Overlaps too much

OK:

Centered

OK:

- centered

- adequate

-

overlap

NOT OK:

- does not

-

overlap enough

-

overlaps too much

- not centered

E. TIPS on how to secure the keyboard