Responsibility of the operator

The operator must ensure the safe operation of the stand and strictly observe the following speci-

fications.

Safe operating condition of the stand

u

Keep unauthorised persons away.

u

Immediately repair any damage. Do not use a damaged stand.

u

Only use original spare parts supplied by the manufacturer.

u

Adhere to the general and local accident prevention regulations.

Responsibility towards the staff

The following requirements must be met:

u

The staff disposes of the required qualifications and has obtained the necessary instructions to

u

operate the stand.

u

The staff has read and understands the operating instructions pertaining to work.

u

The staff should always have access to the operating instructions; therefore, they should be

u

kept near the stand.

Staff requirements

The following requirements must be met by the operating staff:

u

Persons whose ability to react is influenced, for example, by drugs, alcohol or medication are

u

not allowed to carry out any work on the stand.

u

Personnel must observe safety and hazard instructions.

u

Personnel should wear, as appropriate, protective equipment.

u

Personnel must keep the stand and workplace clean.

u

Unauthorised persons are not allowed near the stand.

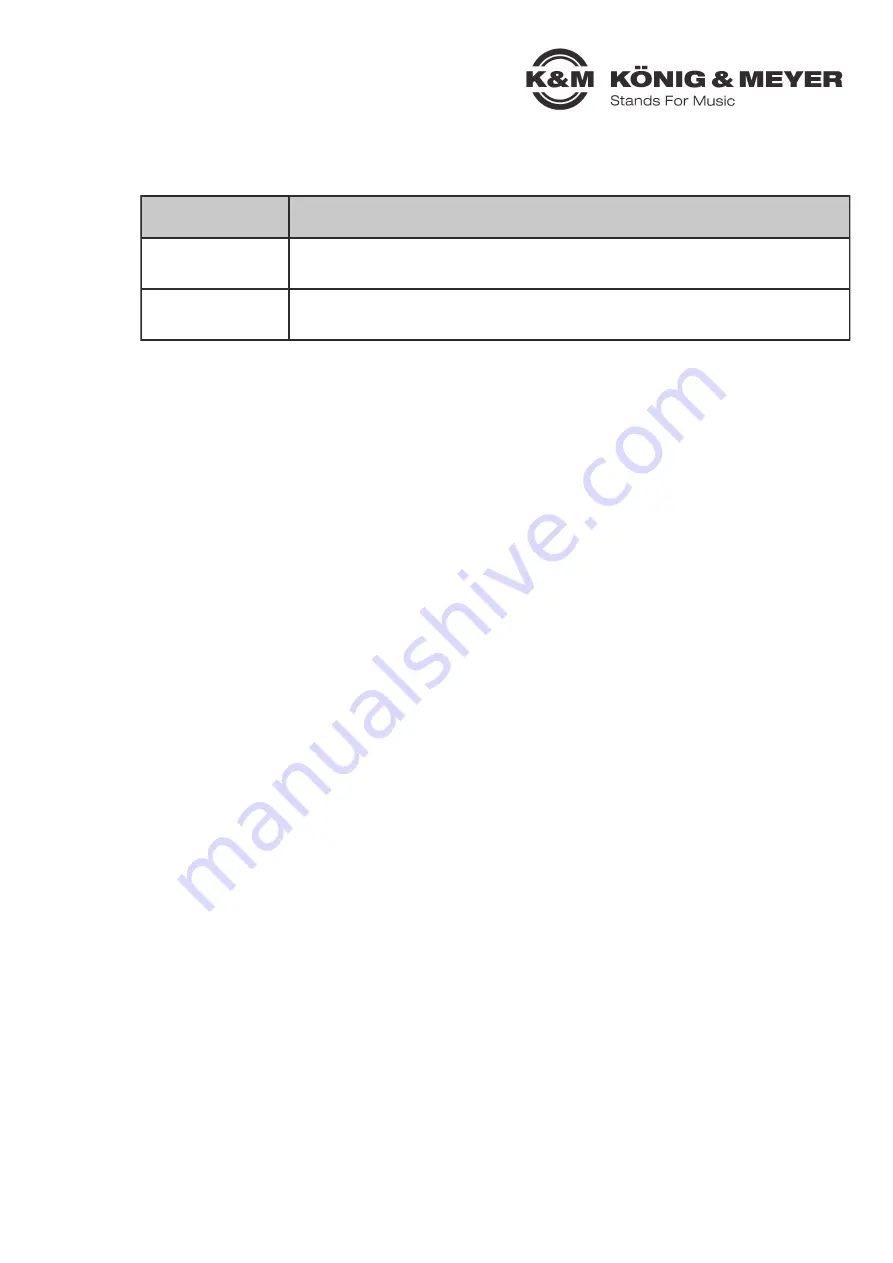

Meaning of signal words and pictograms

The following signal words are used in this document:

Signal word

Meaning, consequences of misapplication

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may

result in minor injuries.

16