26775 Desktop monitor stand

INTENDED USE

- Height-adjustable desktop stand for monitors

-

and many other devices of this size

FEATURES & CAPABILITIES

- Load-bearing capacity up to 25 kg centered load

- Solid, flat stand with 4-point felt support and space for cables

- Functional monitor tray (W x D 205 x 245 mm):

-

- Variable angle adjustment up to 12.5° with safety ledge

-

- Movable to ensure that the load is centered

- Variable height adjustment, double reinforced tube combination

- Data: Height 350 - 500 mm, base 250 x 210 mm, Weight: 3.6 kg

SAFETY NOTES

Thank you for choosing this product. Please read and follow carefully the instructions. They

inform you about all important steps, that are required for a safe assembly and operation. Please

keep the instructions for future reference.

A. GENERAL

A.

- Load-bearing capacity max. 25 kg centered load

A.

- Careful handling required - during all phases of use (

A - F

)

A.

- ACTIVITIES AT THE STAND (change location, extend/retract tube, adjust tray) MUST

A.

-

ALWAYS BE DONE IN UNLOADED CONDITION (e.g. danger of tipping over)

A.

- Keep unauthorized personnel away from the stand

A.

- Only to be used indoors

B. INSTALLATION NOTES

B.

- The surface (desktop) must be suitable, i.e. level and load-bearing

B.

- Wear protective gloves during assembly, if needed

B.

- In particular, during assembly do not drop - or crush limbs

B.

- The side flaps of the tray must face downwards

B.

- Securely screw components (base, tube combination, joint, tray) together

C. STAND SETUP

C.

- Please consider the information provided in the SETUP INSTRUCTIONS

C.

- Screw connections between the base plate and the base tube and between the

C.

-

extension tube and the tray must always be tightened as far as they will go

2.1

C.

- The weight bearing load is not to be placed on the tray until the extension tube

C.

-

height has been adjusted, i.e. when: - the catch

4.4

is always clicked into place;

C.

-

height has been adjusted, i.e. when:

- the clamping screw

4.5

has been tightened

C.

- Note: initially the load is carefully and aligned centrally placed on the tray.

D. PRIOR TO USE

D.

- Prior and after use the stand should undergo visual inspection, to ensure that all

D.

-

components are there and in working order.

D.

- Damaged stands may not be used i.e. the stand must be repaired by a qualified

D.

-

technician.

E. DURING OPERATION

E.

Safety during operation is based on:

E.

1. ...FOLLOWING the points listed here under

A - F

.

E.

2. ...MASTERING the LATERAL FORCES (TIPPING DANGER).

E.

2.

Lateral forces should be avoided at all costs. It occurs in the following cases:

E.

2.

a.

the stand is tilted (uneven surface)

E.

2.

b.

the load bearing weight is not centered

E.

2.

c.

external shocks such as bumping into the stand, brushing into the stand, wind etc.

E.

2.

Lateral forces must be prevented by suitable measures. In the case of items

a.

E.

2.

and

b.

, this is done by correct assembly and placement, and in the case of item

E.

2.

c.

, possibly by safety measures or by maintaining safety distances for unauthorized

E.

2.

persons.

E. DISASSEMBLY

E.

- First remove the load from the tray - then retract or dismantle the stand

SETUP INSTRUCTIONS

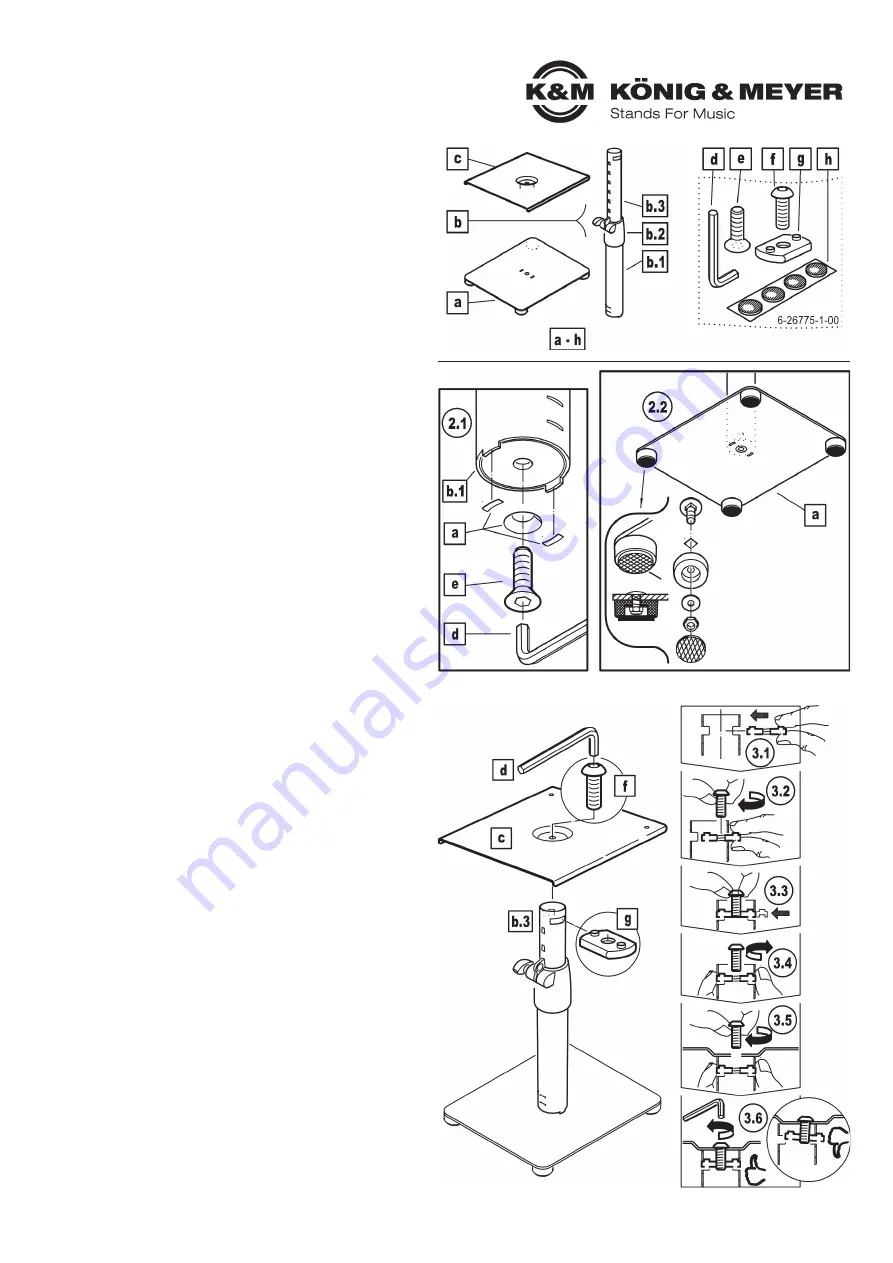

1. COMPONENTS (a-h)

Please carry out a visual inspection to ensure that all parts are included and, as far as can

be seen, are OK:

a

Base plate with the feet

b

Tube combination cpl.:

b.1

base tube,

b.2

clamp,

b.3

extension tube

c

Tray

Accessories bag:

d

Allen key SW5 -

e

countersunk screw M8 x 20 mm

Accessories bag:

f

pan head screw M8 x 20 mm 6.4 mm -

g

threaded link plate M8

Accessories bag:

h

rubber pads (4x)

SETUP

2. STAND

2.1

Insert the two pins of the base tube

b.1

into the slots of the base plate and connect

2.1

both parts using the countersunk screw M8 x 20 mm

e

. Use the SW5 Allen key

d

for

2.1

this purpose.

2.2

Now set up the stand and carefully place it on the surface. To protect it, the base plate

2.2

has 4 feet with a felt pad. Tighten the loosened stand legs again with a socket wrench

2.2

(SW8 = M5).

3. MONITOR TRAY (work with two people if necessary)

3.1

Hold the threaded link plate

g

with the pins facing upwards a little way into one of the

3.1

two side slots of the extension tube

b.3

.

3.2

Loosely screw the pan head screw

f

into the threaded link plate.

3.3

Center the pan head screw so that the threaded link plate fills both side slots of the

3.3

extension tube.

3.4

Hold threaded link plate sideways and remove pan head screw.

3.5

Position the tray

c

centrally and screw in the pan head screw again.

3.5

NOTE: The side flaps of the tray always face downwards.

3.6

Now align the tray as desired and fix this position by tightening the pan head screw

f

3.6

using the Allen key

d

.

3.6

NOTE: The two pins of the threaded link plate g must be located inside the

3.6

extension tube. If they can be seen in the slot or even outside, they must be be

3.6

corrected (see

3.3

).

1. COMPONENTS

2. STAND

3. MONITOR TRAY

M5 / SW8