5

4

User Manual

4

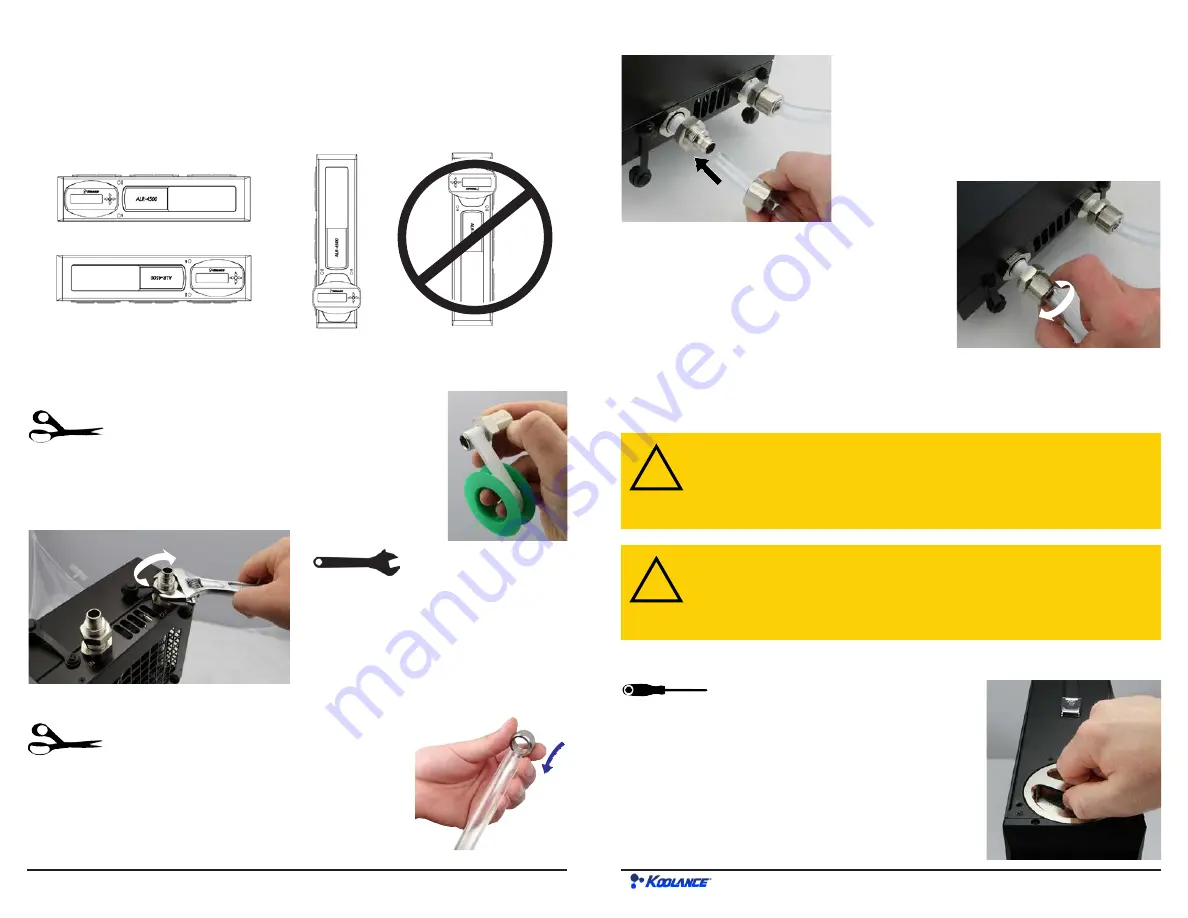

Positioning the System

This product must be operated in a valid upright orientation (shown below). Invalid

orientations can prevent the coolant pump from operating properly.

Coolant Filling and Powering-On

WARNING

:

Most coolants are electrically conductive. Use caution

when filling the system, and keep all liquids away from electronics and

power cables. Keep the primary AC power cable unplugged whenever

filling or draining coolant.

!

CAUTION

:

The cooling system’s pump can not be run dry for any

period of time. Do not power-on the unit without sufficient liquid in

the reservoir. Dry-running (and thereby damaging the pump) is not

covered under the Koolance product warranty.

!

Cut tubing into two segments. You

will need to connect each to the rear

fittings.

Each tubing connection will use a threaded compression

ring or tube clamp to keep it secure. Be sure to thread

the compression ring or tube clamp onto the tubing

before attaching it.

Squeeze the tube while pushing it firmly over

the fitting. Tubing should completely cover the

fitting or barb. This step can be eased by first

dipping the end of the tubing in water.

Tighten the connection by sliding the compression

nut down over the fitting and screwing securely.

For barbed fittings, use pliers to move the clamp

into the proper position before releasing.

Tube fittings are purchased separately.

Threading for the tube fittings is tapered 1/4-inch

NPT. Plumber’s tape (PTFE) is required to seal

them properly.

Tube Fittings

After wrapping with tape, the inlet and

outlet fittings should be inserted by

hand, then finished with a wrench for

the last 1-2 rotations.

Once all devices (cold plates, fittings,

etc.) have been connected with tubing,

the system can be filled with coolant.

The fill port is located above the reservoir. With the fill

port oriented upright, remove the large reservoir cap

by hand or with a hex wrench.