6

Introduction

LED Display - Alarm Settings

By default, the Koolance audio alarm will sound if the primary sensor reaches

55ºC (131ºF). When the system alarm sounds, the LED temperature will

fl

ash in

the display and the radiator fans will increase to 100% power.

To change this setting with the LED Display, press and hold

▲

+

▼

together for

3 seconds. The alarm temperature will begin

fl

ashing. You may change this value

from 0ºC (32ºF) up to 99ºC (210ºF). The normal temperature reading will resume

if you do not press any buttons for 4 seconds.

To reset the temperature alarm to the default (55ºC / 131ºF) setting, press and

hold the

ºC/F

button until “dEF”

fl

ashes in the display. NOTE: This will also reset

the fan speed mode to “auto”.

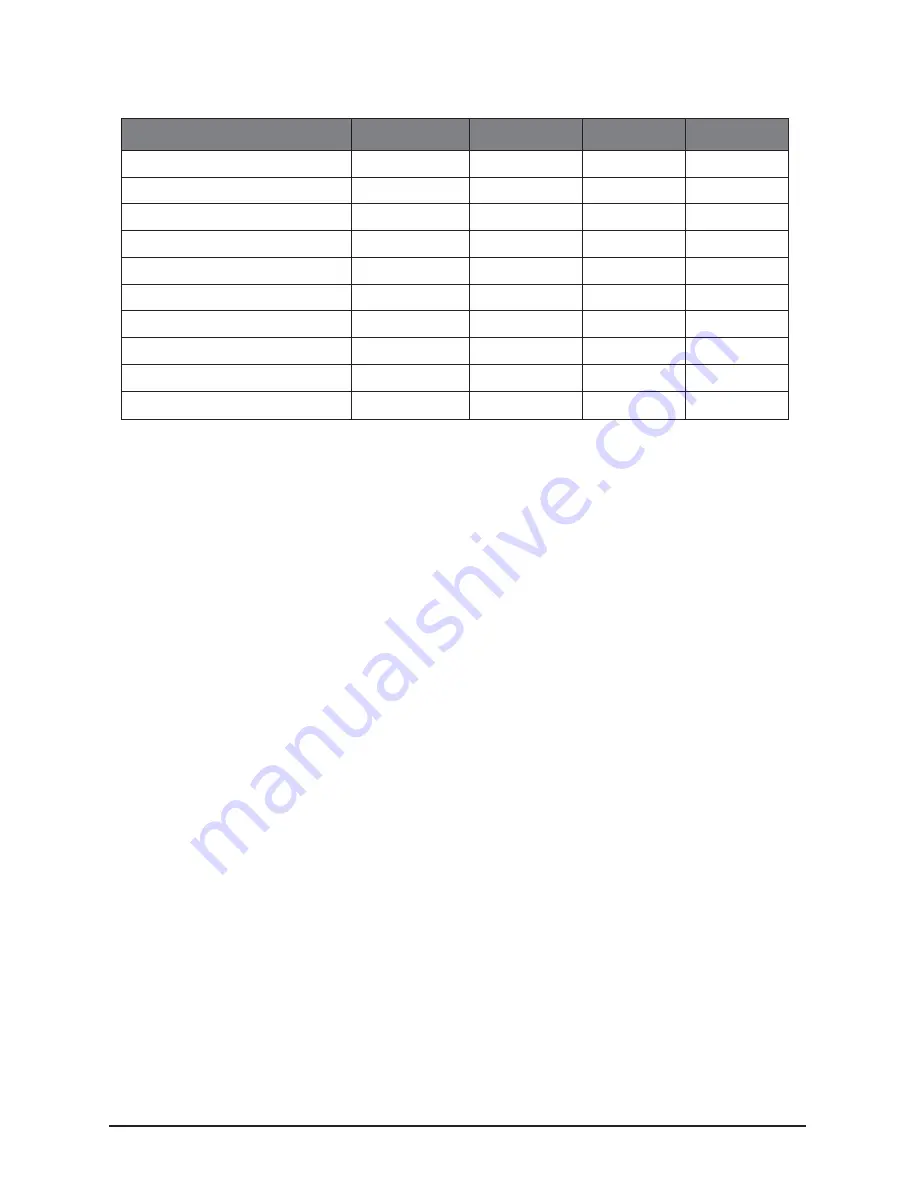

Auto Mode

Manual Mode

Fan Power %

Total CFM

Fan RPM

0 - 35ºC (32 - 95ºF)

1

30

84

720

36 - 37ºC (97 - 99ºF)

2

35

99

840

38 - 39ºC (100 - 102ºF)

3

40

114

960

40 - 41ºC (104 - 106ºF)

4

45

129

1080

42 - 43ºC (108 - 109ºF)

5

50

141

1200

44 - 45ºC (111 - 113ºF)

6

60

171

1440

46 - 47ºC (115 - 117ºF)

7

70

198

1680

48 - 49ºC (118 - 120ºF)

8

80

225

1920

50 - 51ºC (122 - 124ºF)

9

90

255

2160

52 - 99ºC (126 - 210ºF)

10

100

282

2400

Details on fan modes are as follows: