4

5

User Manual

4

System Diagram

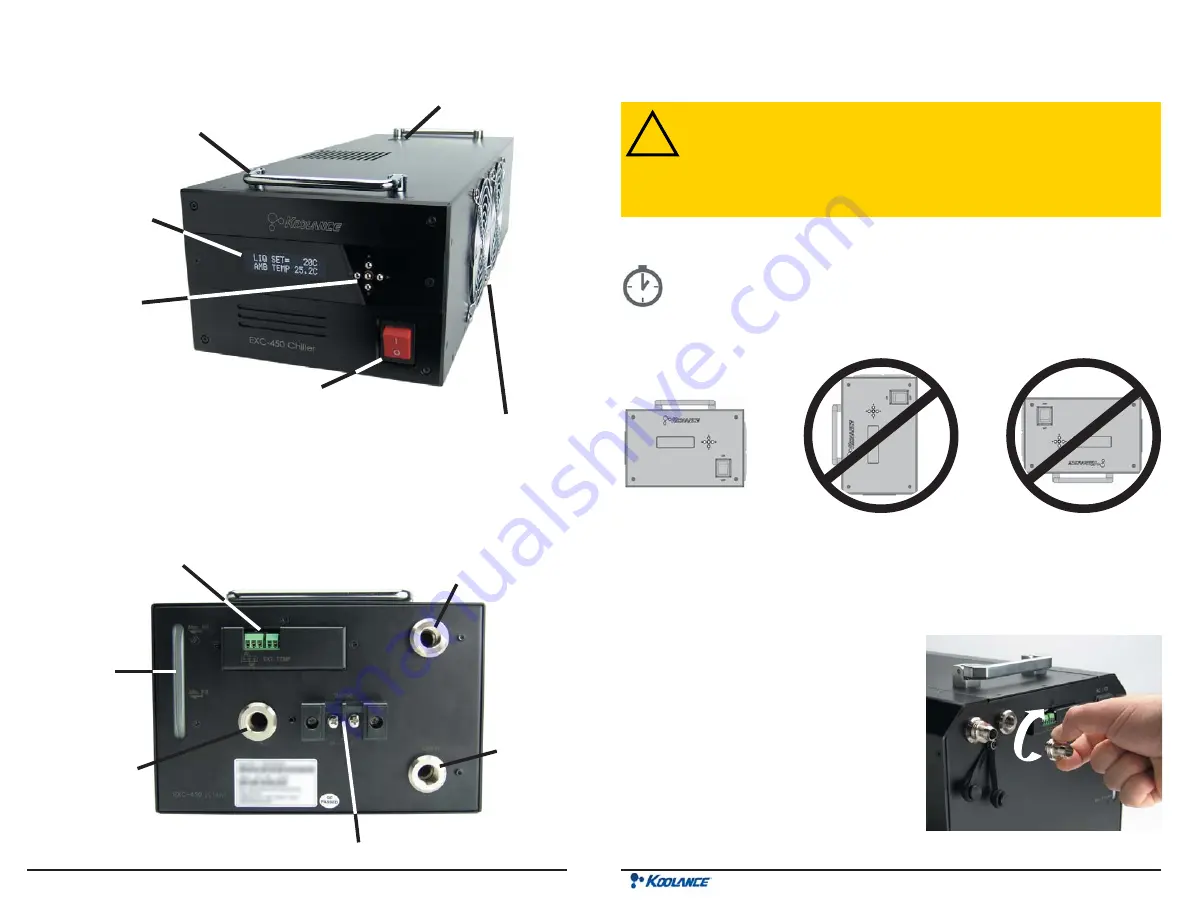

Condenser Fans

LED Display Panel

Carrying Handles

Control Panel

Power Switch

Fill Port

Coolant Outlet

Power Connection

Relay & Thermocouple

Terminals (Optional)

Reservoir

Level

Drain Plug

CAUTION:

Always keep the chiller upright during operation. Additionally,

THE UNIT MUST BE KEPT UPRIGHT FOR AT LEAST 24 HOURS

BEFORE POWERING ON. This is to allow enough oil to reach the

compressor. Powering-on the unit too early can permanently damage

the compressor and is not covered by the product warranty.

!

Positioning the System

The chiller must be run upright at all times. Upon arrival of this product via

transport or courier shipping,

it must be kept upright FOR AT LEAST 24

HOURS BEFORE BEING POWERED ON

to

allow enough oil to reach the

compressor.

OK!

NO!

NO!

External Fittings

Install G 1/4 BSPP threaded fittings you

have purchased into the “Inlet” and “Outlet”

ports. It’s recommended to hand-tighten

all fittings to avoid damaging the cooling

unit.

Parallel threads seal at their o-ring. Do

not use any plumber’s tape or putty on

the threads, which can interfere with the

o-ring seal.

Leave the “Drain” plug installed. This is only

opened when emptying coolant.

Coolant Inlet