8

9

User Manual

8

User Manual

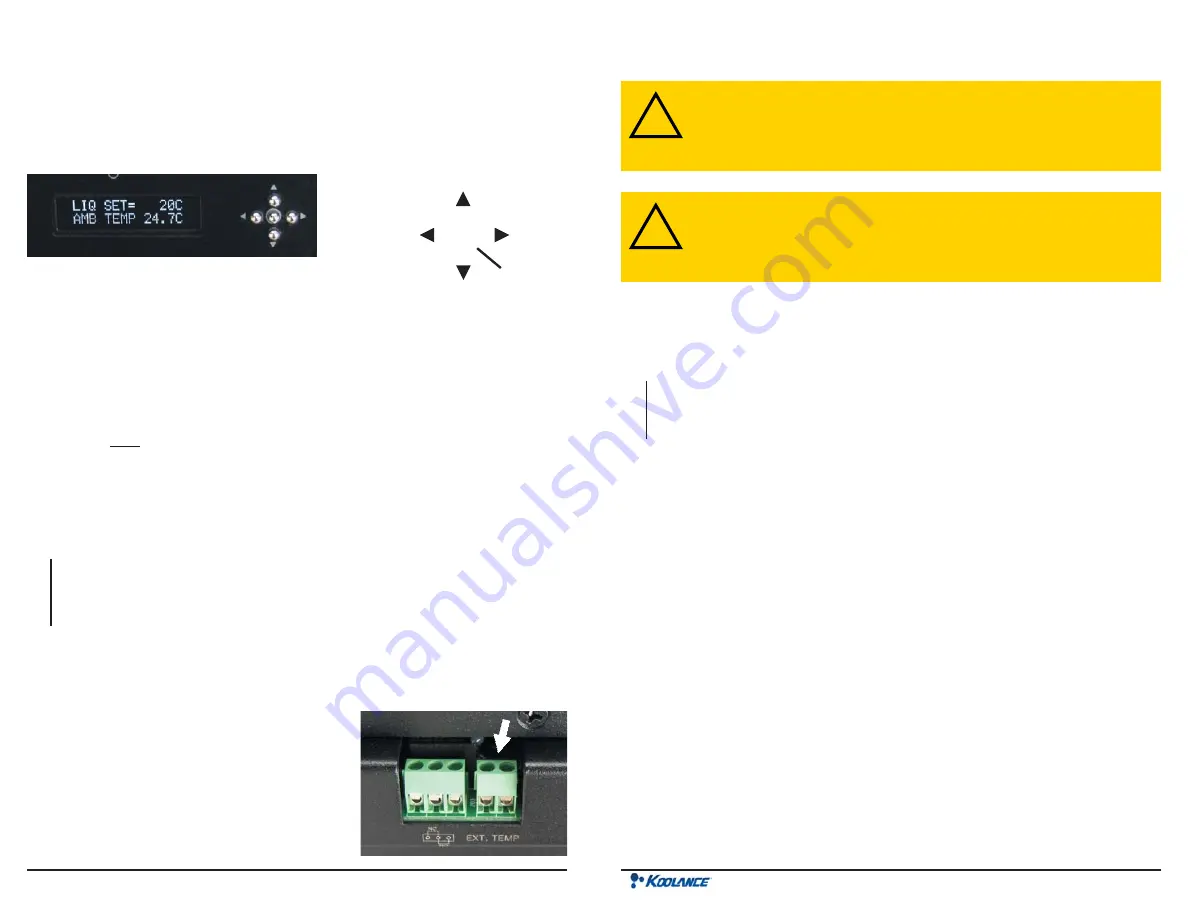

Display Panel

The Koolance display panel allows control and monitoring of various aspects of

the cooling unit. 5 buttons are used, with directional arrows to navigate or change

settings, and a center button to select/exit.

• On the main screen, hold

◙

for 3 seconds to change display units between

°C/°F and LPM/GPM.

• You can exit any menu and return to the main screen by holding

◙

for 2

seconds.

• To reset

ALL

settings to default, hold

▼

+

▲

for 3 seconds.

Main Menu

To enter the main menu, briefly press

◙

. The selected option will begin flashing.

Use

▼

and

▲

to navigate this menu.

TEMP SET

: Temperature set-point adjustment

ALARM SET

: Alarm settings

RELAY SET

: Relay Trigger settings

PUMP SET

: Pump speed settings

DISPLAY SET

: LCD display settings

When in the top menu, press

◙

to enter one of the above categories. To exit from

here, press

◄

.

External Sensor

This unit provides a terminal on the rear for

connecting a K-type thermocouple (not included)

for external monitoring and temperature

configuration.

Navigate Up,

Increase Setting

Navigate Down,

Decrease Setting

Navigate

Left

Navigate

Right

Enter/Exit

◙

▲

▼

Under “TEMP SET”, you can select the active temperature sensor and set-point

the chiller will try to follow. There are four temperature options to select from.

Press

▼

and

▲

to scroll among these options:

LIQ TEMP

: Liquid temperature (Range: 1 to 50°C)

EXT TEMP

: Rear sensor, if attached (Range: 1 to 149°C)

LIQ-AMB

: Delta-T between liquid & ambient (Range: -50 to 50°C)

EXT-AMB

: Delta-T between rear sensor & ambient (Range: -50 to 50°C)

The sensor currently displayed in this menu is what the chiller will follow.

Only one can be active.

Press

◙

to adjust the target temperature value using

▼

and

▲

. Below are some examples:

LIQ TEMP= 28C

Maintain coolant coming from the chiller at 28°C

EXT TEMP= 50C

Maintain the external sensor at 50°C (if attached)

LIQ-AMB= -5C

Maintain a difference between the liquid and ambient

air of -5°C (keep liquid 5°C below ambient)

EXT-AMB= 5C

Maintain a difference between the external sensor and

ambient air of +5°C (keep sensor 5ºC above ambient)

Press

◙

again to exit configuration of the sensor. Press

◄

to return to the previous

menu.

With these settings, it’s possible to set the liquid temperature below the environmental

air temperature. If liquid temperatures reach the ambient dew point, condensation

(water droplets) can form on tubing and cold plates connected to the chiller. Unless

condensation is prepared for,

it is recommended to keep the chiller on “LIQ-

AMB” with a minimum value of 0°C (which keeps liquid at ambient).

▲

▼

TEMP SET

CAUTION:

This cooling system can chill liquid below the ambient air

temperature, which may cause condensation to form on tubing and

cold plates. It is highly recommended to keep the temperature at or

above the ambient temperature. (See below for details.)

!

CAUTION:

Do not use a temperature set-point that is below the

coolant’s freezing point. This may damage the cooling unit and is not

covered by the product warranty. It is recommended to always keep

the temperature set-point at or above ambient temperature.

!