Service manual EKCO.T/EKCO.TM

10

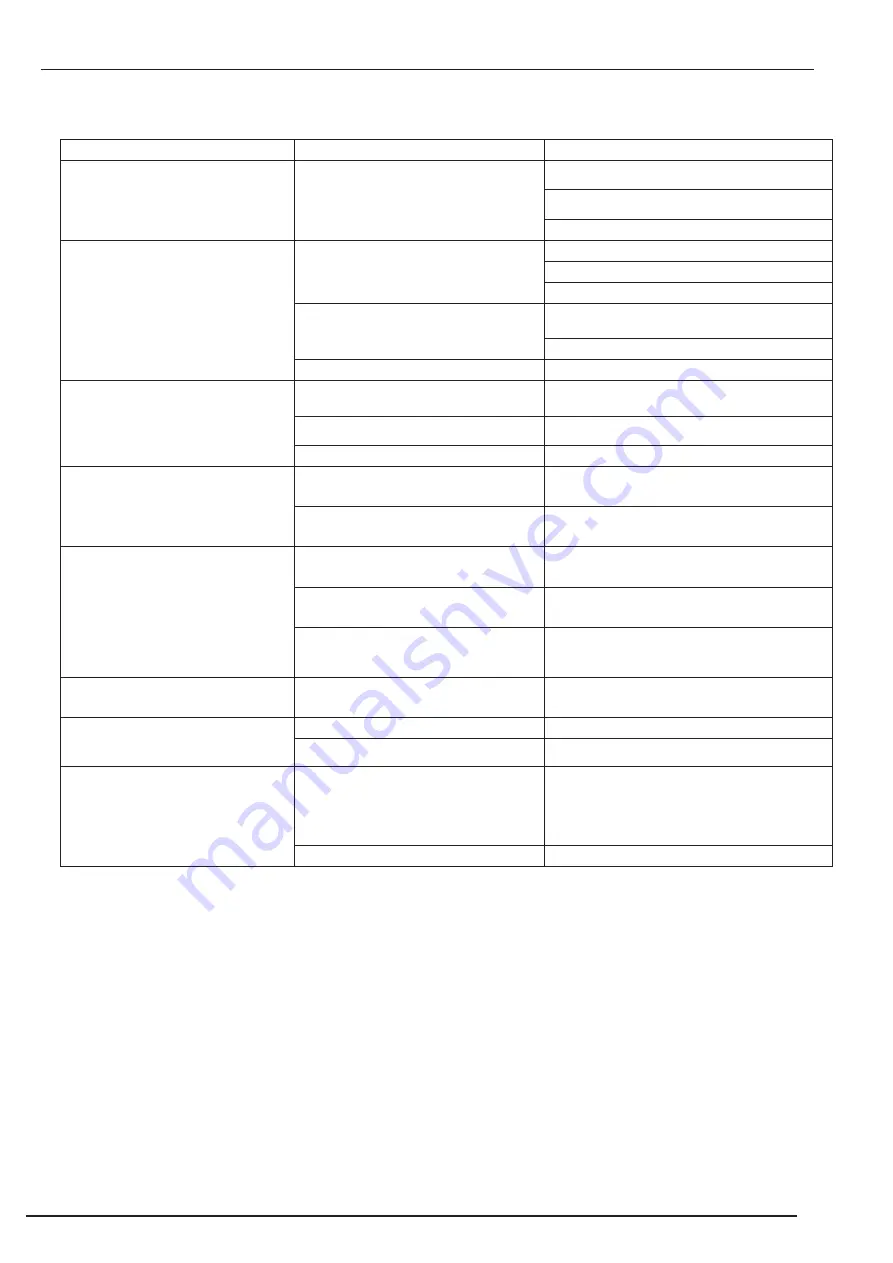

Tab.1 Failures

Symptoms

Reason

Operation

Control panel

JOEJDBUPSTBSFPò

Power supply failure.

Check the mains and the main fuses.

$IFDLUIF85UFNQFSBUVSFDVUPò

Replace the control panel.

indicator "2" is blinking.

The flow value is „0” or is to low.

(below value of 12 l/min)

Heating is blocked.

Check the pump fuse on ZIO23 board.

Air lock in the heating system, solve the problem.

Deaerate the pump and the heating system.

Circulating pump is blocked.

Circulating pump is blocked. Make a manual pump

run. Use the screw to rotate the rotor.

Replace pump.

Flow sensor failure.

Replace flow sensor.

Room thermostat start heating

and the "3" indicator on the

DPOUSPMQBOFMJTOPUPò

The room thermostat wiring connection

failure.

Check the room thermostat wiring connection.

Room thermostat failure.

Replace room thermostat.

ZIO 23 failure.

Replace ZIO 23 board.

The "1" indicator is on

The boiler is heating only central heating

The three-way valve failure

Check the servo. Replace the servo of valve

ZIO 23 failure

Replace ZIO 23 board

DHW temperature is too low.

The boiler is heating only the heating

system.

5IFJOEJDBUPSJTPò

The DHWT thermostat or DHWT electronic

Sensor (DS 1820) failure

Replace DHWT thermostat or electronic sensor

(DS 1820)

ZIO 23 failure

Replace ZIO 23 board

Too low DHWT temperature settings

Set the higher temperature on the DHWT

thermostat or rise the DHWT temperature on the

control panel (for the electronic sensor DS 1820)

The supply temperature is too low

Heating box failure.

Check or replace heating box.

The NA connector is opened by the

superior device.

The "3" indicator does not blink

RP connector opened

Check the room thermostat

Control panel failure PSK.P4

Replace front panel

Control panel indicators

are blinking or temperature indicator is

blinking or the

return or supply temperature

JOEJDBUPSJTTIPXJOH¡$

Return or supply temperature sensor.

Use the right arrow to view the return inlet and

flow outlet temperature. If the „E” symbol or 99 is

displayed replace the required sensor.

(Nominal resistance of the temperature sensor

LȰBU¡$

Control panel failure

Replace the control panel PSK.P4

3.2

Failure modes of PSK.P4 front panel.

Summary of Contents for ECKO.TM

Page 1: ...1 KOSPEL S A KOSZALIN ul Olchowa 1 SERVICE MANUAL EKCO T ECKO TM 17 11 2020 ...

Page 5: ...5 Pic 1b EKCO TM boiler 5 01216 19 01220 23 00035 32 6 01217 ...

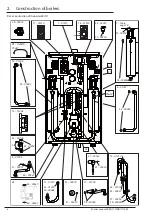

Page 7: ...7 Pic 2bConstruction of the boiler EKCO TM ...

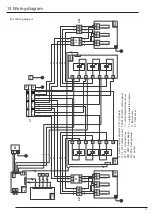

Page 26: ...Service manual EKCO T EKCO TM 26 14 2 Pump Wilo Yonos Para alarm status Tab 7 Alarm status ...