16

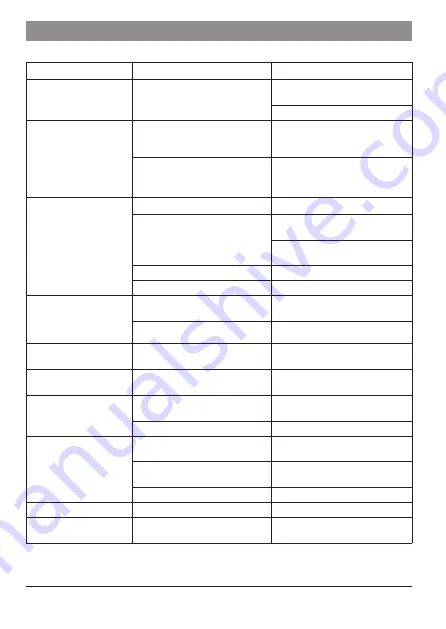

Symptom

Reason

Action

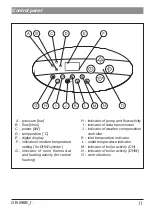

the indicators on

control panel are off

lack of boiler power supply

check parameters of power

network and fuses

contact authorised service

A indicator flickers

insufficient pressure (below

0,5 bar)

shift the controller to the pressure

view, increase pressure within the

installation to required level

pressure sensor failure

switch the controller to pressure

preview, if display E indicates "--"

contact authorised service

H indicator flickers

pump's blockage

unblock pump's rotor

lack of medium's flow through the

boiler- boiler's blockage

an air-bound central heating system,

vent the installation, pump and boiler

check patency of CH installation

and clean the filter

failure of pump's power supply

contact authorised service

failure of pump or flow sensor

contact authorised service

G indicator is off (in

winter mode), room

thermostat indicates

heating on

failure of installation that con-

nects room thermostat

check connecting installation

failure of electronic module

contact authorised service

K indicator flickers

failure of inlet temp. sensor, boiler

shifted to failure condition

contact authorised service

L indicator flickers

failure of outlet temp. sensor,

heating blockage

contact authorised service

G indicator flickers and

the boiler doesn't work

failure of installation that connects

master appliance

check connecting installation

failure of electronic module

contact authorised service

EKCO.LN2M and EKCO.

L2M model doesn’t heat

the cylinder

failure of cylinder's temp. sensor

or thermostat

contact authorised service, replace

temp. sensor or thermostat

failure of three-way valve servo-

motor

replace rotor

failure of electronic module

contact authorised service

J indicator flickers

failure of external temp. sensor

contact authorized service

N indicator flickers (red) failure of cylinder water temp.

sensor

contact authorized service

Failures