7

GB-096B_f.

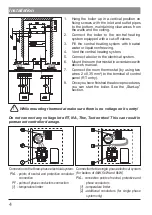

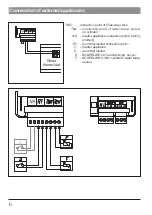

Room thermostat (RT entry) –

when the voltage free contact gets opened the boiler

will stop heating. The entry is responsible for boiler's control depending on the room

temperature (room thermostat connection details – section 'Installation ', sub clause 7).

Master appliance (NA entry)

– you can limit the power used, i.e. the boiler can be

switched off while another appliance consumes electricity. To do it, an electrician should

install in line an extra open contact to the NA entry (voltage free entry), so that when

a master appliance gets on, the contact will be opened the boiler switched off. When the

NA contact gets opened, heating will get off and the pump stopped. The EKCO.LN2 and

EKCO.L2 model may also work as second boiler. If it is so, the master boiler by opening

the NA entry will stop heating of EKCO. However, the mode of the three-way valve

control stays on so a DHW cylinder is charged by the heat from the different heat source.

WE-019/01 cylinder water temperature sensor (Thw entry) -

for connection details

please, refer to the figure. If there is need to extend the wire- it is necessary to make

it as short as possible. If the wire is too long there may occur disturbances and it may

not work properly. The wires should not run close to mains cables and they must not

go around other electric wires.

Note! To activate sensor and DHW cylinder heating function, please follow the

instructions in section „Advanced settings”.

Three way divert valve (TWV entry) -

the valve has to be connected in accordance

with the diagram on page 18-19 depending on the model. Note: in order to activate

DHW function one must follow the instructions in the section 'Advanced settings'.

WE-027 outside temperature sensor (Text entry) -

for connection details please, refer to

the figure. If there is need to extend the wire- it is necessary to make it as short as possible.

If the wire is too long there may occur disturbances and it may not work properly.

The wires should not run close to mains cables and they must not go around other

electric wires. It is recommended to mount the sensor on the northern or north-west

facade of the building away from windows and exhaust fans.

Note! If outside temperature sensor hasn't been connected then it is necessary

to switch off weather compesation (heating curve coefficient, weather

compensation switch off > C=0 )